Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Led Strips Lighting Project From Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Led Strips Lighting Project From:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

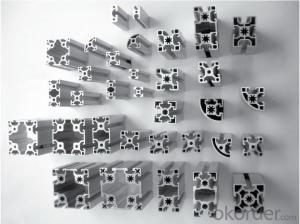

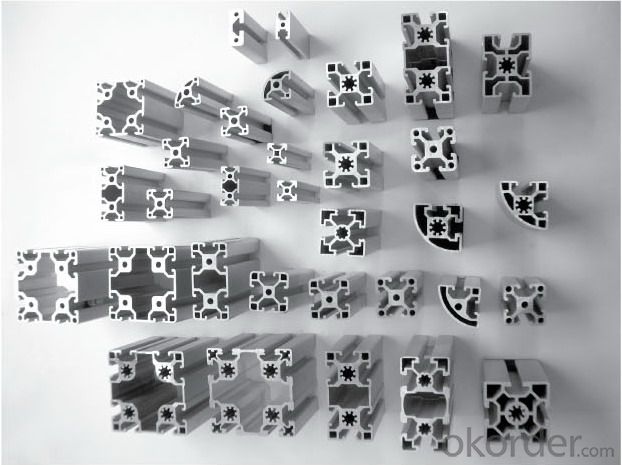

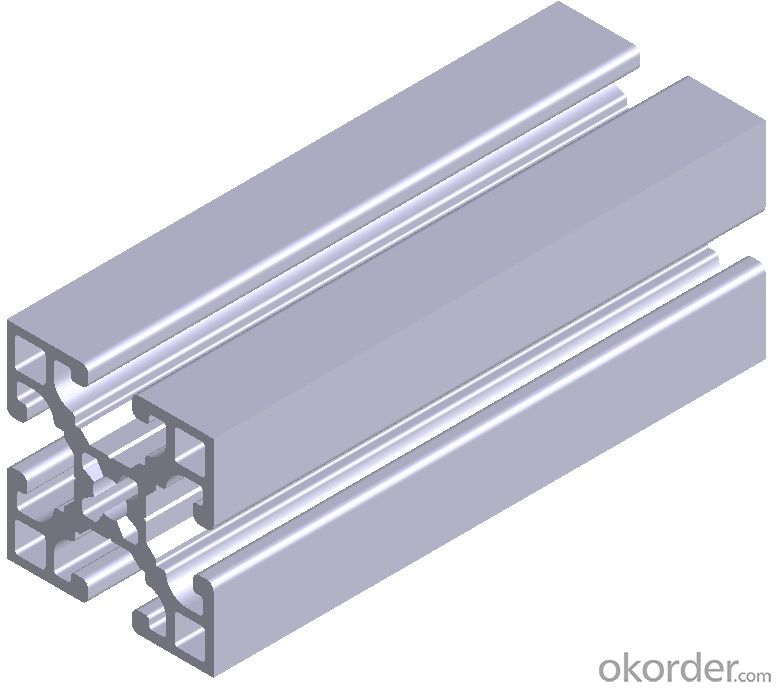

Images of the Aluminium Profile for Led Strips Lighting Project From:

Aluminium Profile for Led Strips Lighting Project From Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used for skylights?

- Yes, aluminum profiles can be used for skylights. Aluminum is a popular material choice for skylight frames due to its durability, strength, and resistance to corrosion. It is lightweight yet sturdy, making it suitable for supporting the weight of skylight glass while ensuring long-lasting performance. Additionally, aluminum profiles can be easily customized and shaped to meet specific design requirements, allowing for various skylight styles and sizes. The use of aluminum profiles in skylights also provides excellent thermal insulation properties, contributing to energy efficiency by reducing heat transfer and preventing condensation. Overall, aluminum profiles are a reliable and practical option for constructing skylights.

- Q: Can aluminum profiles be used in lighting fixture manufacturing?

- Aluminum profiles are indeed suitable for the manufacturing of lighting fixtures. In the lighting industry, aluminum is widely employed because of its many advantageous qualities. It possesses light weight, durability, and corrosion resistance, which make it perfect for both indoor and outdoor lighting fixtures. By easily molding and manipulating aluminum profiles, one can create diverse designs and forms, thereby enabling innovative and imaginative lighting solutions. Moreover, these profiles can be coated or anodized, thereby enhancing their visual appeal and providing extra protection against damage. All in all, due to their versatility, functionality, and aesthetic appeal, aluminum profiles are highly favored in the manufacturing of lighting fixtures.

- Q: Can aluminum profiles be used in modular construction systems?

- Yes, aluminum profiles can be used in modular construction systems. Aluminum is a popular choice for modular construction due to its lightweight, strong, and durable properties. It is versatile and can be easily customized to fit various modular construction needs, making it a suitable material for framing, cladding, and other structural components in modular buildings.

- Q: Aluminum prices are calculated by the meter, or how to quote the ah?

- Yes, for example, today's aluminum price, 10340+ processing fee 4000=14340, in addition to 1000 is equal to 14.34 yuan /KG

- Q: This question asks about the various types of aluminum profiles that are utilized in interior design applications.

- <p>Aluminum profiles are widely used in interior design for their strength, durability, and aesthetic appeal. Common types include: 1. Linear Profiles for creating sleek lines in furniture and architectural elements; 2. Structural Profiles for load-bearing structures like beams and columns; 3. Decorative Profiles for ornamental purposes, such as moldings and trims; 4. Frame Profiles for framing pictures, mirrors, and other wall-mounted items; 5. Slatwall Profiles for versatile display systems in retail spaces; 6. Handrail Profiles for stairways and balconies, ensuring safety and style; 7. Window and Door Profiles for modern, lightweight, and energy-efficient applications. Each type is chosen based on the specific design requirements and functional needs of the space.</p>

- Q: What are the different surface protection methods for aluminum profiles?

- There are several surface protection methods for aluminum profiles, including anodizing, powder coating, painting, and mechanical finishes. Anodizing is a popular method that creates a protective oxide layer on the surface, providing corrosion resistance and enhancing the appearance. Powder coating involves applying a dry powder onto the profile, which is then cured to create a durable and decorative finish. Painting is another option, where a liquid paint is applied and cured to protect the surface. Mechanical finishes involve processes like brushing or polishing to achieve a desired texture or appearance while still protecting the aluminum profile.

- Q: Are aluminum profiles suitable for conveyor rollers?

- Yes, aluminum profiles are suitable for conveyor rollers. Aluminum is a lightweight and durable material that offers various advantages for conveyor systems. Firstly, aluminum profiles provide excellent strength-to-weight ratio, making them ideal for conveyor rollers. They are strong enough to handle the weight of materials being transported while being light enough to reduce the overall weight of the conveyor system, resulting in energy savings and easier handling during installation and maintenance. Additionally, aluminum profiles offer excellent corrosion resistance, which is crucial for conveyor systems operating in harsh environments, such as those exposed to moisture or chemicals. This corrosion resistance ensures the longevity and reliability of the conveyor rollers, reducing maintenance requirements and costs. Moreover, aluminum profiles can be easily customized and fabricated to fit specific conveyor system requirements. They can be extruded into various shapes and sizes, allowing for the creation of conveyor rollers that perfectly match the application's needs. This versatility makes aluminum profiles highly adaptable and suitable for a wide range of conveyor systems, including those in industries such as manufacturing, packaging, and logistics. Furthermore, aluminum is a highly sustainable material as it is 100% recyclable, making it an environmentally friendly choice for conveyor rollers. By using aluminum profiles, companies can contribute to their sustainability goals and reduce their carbon footprint. In conclusion, aluminum profiles are indeed suitable for conveyor rollers due to their lightweight, durable, corrosion-resistant, customizable, and sustainable properties.

- Q: This question asks about the various finishing options that can be applied to aluminum profiles.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance and durability. Common types of finishes include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, a durable and customizable finish that offers a wide range of colors and textures. 3. Electrophoretic coating, which results in a smooth, even finish and is often used for automotive parts. 4. Polishing, which can produce a mirror-like finish. 5. Brushing, which creates a鍝戝厜 texture with a satin-like appearance. 6. Painting, which can be done with solvent-based or water-based paints for a variety of color options. 7. Wood grain transfer, which gives aluminum profiles the appearance of wood. Each finish has its own advantages and is chosen based on the specific application and aesthetic requirements.</p>

- Q: What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, including mechanical fastening methods such as screws, bolts, and rivets. Additionally, adhesive bonding and welding techniques can also be used to join aluminum profiles together. The choice of assembly method depends on factors such as the desired strength, aesthetics, and ease of disassembly if required.

- Q: What are the different surface finishing options available for aluminum profiles?

- There are several surface finishing options available for aluminum profiles, each offering different benefits and aesthetic appearances. Some of the commonly used surface finishing options for aluminum profiles include: 1. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This process not only enhances corrosion resistance but also provides a variety of color options. Anodized aluminum profiles are durable, easy to maintain, and have a smooth, attractive finish. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profile and then curing it under heat. This process creates a tough, decorative finish that is resistant to chipping, scratching, and fading. Powder coating offers a wide range of color options and can be customized to achieve different textures and effects. 3. Polishing: Polishing is a mechanical process that creates a high-gloss, reflective finish on the aluminum profile. It involves using abrasives and polishing compounds to remove surface imperfections and achieve a smooth, mirror-like appearance. Polished aluminum profiles are commonly used in decorative applications where a sleek and shiny finish is desired. 4. Brushing: Brushing involves using abrasive brushes or pads to create a textured, brushed finish on the aluminum profile. This process produces parallel lines or circular patterns on the surface, giving it a unique and stylish appearance. Brushed aluminum profiles are often used in architectural and interior design applications. 5. Electrophoretic Coating: Electrophoretic coating, also known as e-coating, is an immersion process where an electrically charged paint is applied to the aluminum profile. This process ensures uniform coating thickness and excellent corrosion resistance. E-coating provides a smooth, even finish and is commonly used in automotive and industrial applications. 6. Wood Grain Effect: Aluminum profiles can be treated with a special coating to mimic the appearance of wood grain. This option is popular in architectural applications where the durability and low maintenance of aluminum are preferred over natural wood. These are just a few of the surface finishing options available for aluminum profiles. The choice of finishing method depends on the desired appearance, functionality, and intended application of the aluminum profile.

Send your message to us

Aluminum Extrusion Profiles Japanese for LED Strips Lighting Project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords