Aluminum Extrusion Profiles 80/20 - Aluminum Sheet, Plate, Slab, and Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

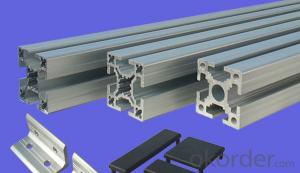

1.Structure of Product Description

Cold rolled and hot rolled and cold drawn and hot drawn aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22,O,FO,H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000,500*500,800*800,900*700mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum profiles suitable for use in exterior wall cladding systems?

- <p>Yes, aluminum profiles are commonly used for exterior wall cladding systems. They offer several advantages, including corrosion resistance, low maintenance, and durability. Aluminum profiles are lightweight, which makes them easy to install, and they can be designed to provide thermal insulation. Additionally, they can be powder-coated in various colors, offering aesthetic flexibility. However, it's important to ensure that the profiles meet the necessary standards for weather resistance and structural integrity.</p>

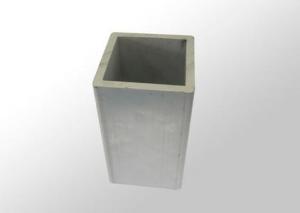

- Q: Can aluminum profiles be extruded into hollow profiles?

- Yes, like aluminum tubes. This is hollow

- Q: Can aluminum profiles be used in medical equipment manufacturing?

- Yes, aluminum profiles can be used in medical equipment manufacturing. Aluminum is a lightweight and durable material that offers various advantages for medical applications. It is corrosion-resistant, which is crucial in medical settings where equipment is often exposed to chemicals and sterilization processes. Aluminum profiles also provide excellent thermal conductivity, allowing for efficient heat dissipation in medical devices. Furthermore, aluminum profiles can be easily customized to meet specific design requirements, allowing for the creation of complex and precise medical equipment. They can be machined, welded, and formed into various shapes and sizes, making them suitable for a wide range of medical applications, such as surgical instruments, imaging equipment, patient beds, and wheelchairs. In addition to its mechanical properties, aluminum is environmentally friendly and recyclable, aligning with the growing sustainability requirements in the medical industry. It is non-toxic and does not release harmful substances, ensuring the safety of patients and healthcare professionals. Overall, aluminum profiles offer numerous benefits for medical equipment manufacturing, including durability, corrosion resistance, thermal conductivity, customization options, and sustainability.

- Q: Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: Is it possible to use aluminum profiles as a material for exterior walls or facades?

- <p>Yes, aluminum profiles can be used for exterior cladding or siding. They are known for their durability, low maintenance, and resistance to weather and corrosion, making them ideal for exterior applications. Aluminum profiles are lightweight, easy to install, and can be painted or finished in various ways to match architectural designs. They also offer excellent thermal performance and can be recycled, contributing to sustainability.</p>

- Q: This question asks for methods to ensure the reliable and durable installation of aluminum profiles.

- <p>To ensure the reliable and durable installation of aluminum profiles, follow these steps: Use high-quality aluminum materials that meet industry standards for strength and durability. Ensure proper alignment and level during installation to prevent warping or stress on the profiles. Use appropriate fasteners and adhesives recommended for aluminum to ensure a strong bond. Avoid over-tightening fasteners, which can cause deformation. Regularly inspect and maintain the profiles to check for signs of wear or damage, and address any issues promptly. This will help maintain the integrity and longevity of the aluminum profiles.</p>

- Q: This question asks for a list of various aluminum profiles that are utilized in the construction of building facades and cladding systems.

- <p>Aluminum profiles for facades and cladding systems come in various types, each serving specific purposes in construction. Common types include: 1. <strong>Aluminum Extrusions</strong>: Used for structural support and can be customized for specific design requirements. 2. <strong>Aluminum Channels</strong>: Often used for attaching panels or as a part of the support structure. 3. <strong>Aluminum Angles</strong>: Provide corner support and reinforcement. 4. <strong>Aluminum Flat Bars</strong>: Used for horizontal or vertical support in facade systems. 5. <strong>Aluminum Tubes</strong>: Can be used as a decorative element or for structural reinforcement. 6. <strong>Aluminum Louvers</strong>: Designed for sun shading and ventilation. 7. <strong>Aluminum Panels</strong>: Can be flat or profiled, used for the outer layer of the facade. 8. <strong>Aluminum Trims and Mouldings</strong>: Used for finishing and detailing around windows, doors, and edges. Each type is chosen based on the architectural design, structural requirements, and aesthetic preferences.</p>

- Q: Are aluminum profiles suitable for exterior cladding systems that need to withstand fire?

- <p>Yes, aluminum profiles can be used for exterior cladding systems that require fire resistance. Aluminum is a non-combustible material, which means it does not support combustion. However, it's important to note that while aluminum itself doesn't burn, it can melt at high temperatures. To enhance fire resistance, aluminum profiles can be coated with intumescent paint or used with fire-resistant materials in the cladding system. These measures can help to slow the spread of fire and protect the structure. Always ensure compliance with local building codes and fire safety regulations when selecting materials for fire-resistant applications.</p>

- Q: How to identify and distinguish the inferior aluminum profile and the poor aluminum profile four?

- Third, the chemical composition is not qualified.Some manufacturers in order to retain customers, at the incorporation of a large number of miscellaneous scrap aluminum, aluminum can greatly reduce the cost, but will lead to industrial aluminum unqualified chemical compositions, seriously endanger the life of aluminum.Fourth, reduce the wall thickness of profiles.

Send your message to us

Aluminum Extrusion Profiles 80/20 - Aluminum Sheet, Plate, Slab, and Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords