Sublimation Aluminum Sheets for Trailer Tool Case - Aluminum Embossed Panel Atlanta GA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Embossed Panel for Trailer Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Embossed Panel for Trailer Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Embossed Panel for Trailer Tool Case

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

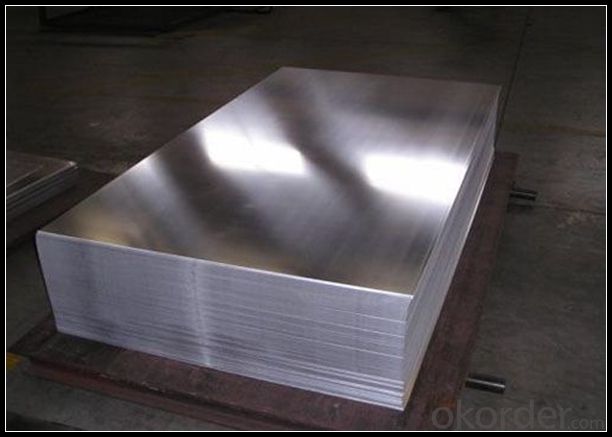

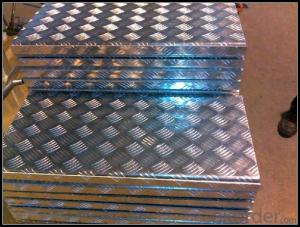

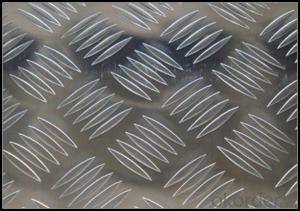

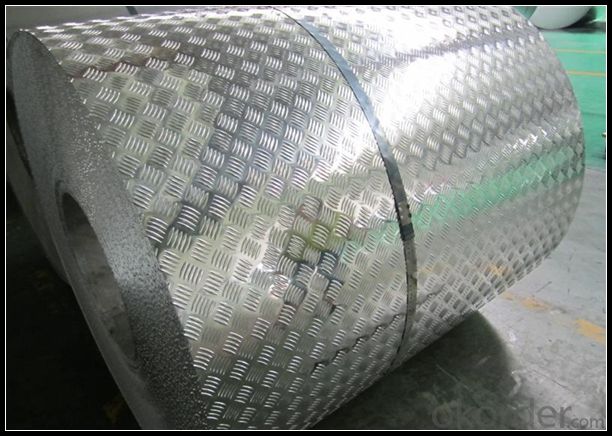

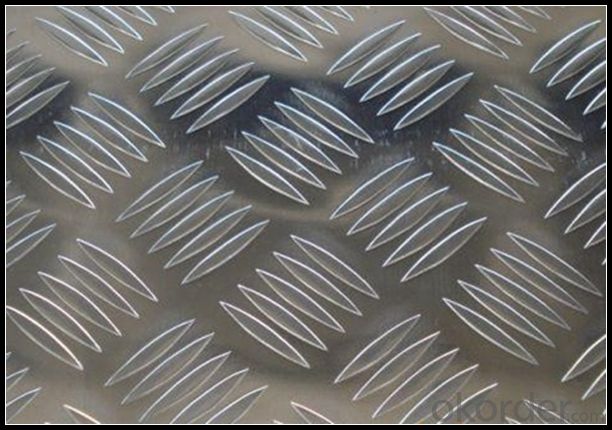

5. Image of Aluminum Embossed Panel for Trailer Tool Case

6. Package and shipping of Aluminum Embossed Panel for Trailer Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- How old are you do you not know how to cook of course it wont burn silly

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: What are the effects of utilizing aluminum sheets on the environment?

- <p>The environmental impact of using aluminum sheets includes both positive and negative aspects. On the positive side, aluminum is recyclable, and its use in construction and manufacturing can reduce the need for more energy-intensive materials like steel. However, the production process of aluminum is energy-intensive and generates greenhouse gases, contributing to climate change. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Despite these concerns, aluminum's lightweight nature can reduce energy consumption in transportation, and its durability can extend the lifespan of products, reducing waste. Overall, the environmental impact depends on the balance between these factors and the specific context of use.</p>

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: I'm buying a sword this afternoon for about 100 bucks i'm using it mainly to take pictures of and hang it on my wall. I looked up tips about buying swords and i think the sword i want is made out of aluminum. Could i use this sword as protection on an armed robber who would break into my house?

- Nothing wrong with buying a wall hanger. In a worst case scenario: sure. Pointy end goes into the other guy. But you are far better off with a kitchen knife, that has a whole lot less chance of breaking or shattering and injuring you, plus you don't need any room with it. Against an armed robber, more than likely you would get killed. Sword work even for guys trained with it, doesn't work great in tight spaces like halls. Having zero training with a sword and attempting to use it, will more than likely result in your injury even if you were just playing around and not attempting to fight for your life. If you are truly interested or worried about home protection, a shotgun is best, a handgun would be next, and even then some time at the range and some qualified instruction is needed. As a last resort matter of life or death, you are scrambling and only your wall hanger is available, sure it gives you a slight edge over being unarmed (maybe). It also hampers you, it ties up both of your hands, it requires space to use, and more than likely would break or severely bend the first time it contacts anything hard, it also elevates your threat level to an armed robber. Meaning he will be more willing to shoot you fearing his life is in danger. Or it could go the other way completely and scare the guy off... no telling. I wouldn't rely on it as a sole means of home protection, or even as an item of last resort (again see kitchen knife). For home protection, get a dog, get an alarm, and get a gun. Shotgun is point and shoot, without a lot of worry of penetration through walls and such injuring other members of your house. Handgun requires some training but is very effective. I can tell you that the unique sound of racking a shell on a pump action shotgun is a very effective intimidator and deterrant.

- Q: how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can be used in the construction industry. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various construction applications such as roofing, cladding, windows, and doors.

- Q: Are 101 aluminum sheets suitable for solar panel frames?

- Yes, 101 aluminum sheets are generally suitable for solar panel frames due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

Send your message to us

Sublimation Aluminum Sheets for Trailer Tool Case - Aluminum Embossed Panel Atlanta GA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords