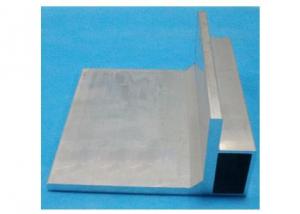

Shampagn Powder Coated Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 25,000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Fashionable

2) Different inner and outer color forms

3) Stable structure and sound texture, without fading

4) MOQ: 1 ton

Why chooses us?

1. ISO certified manufacturer in Guangdong,China,

2.Specialized in R&D ,maketing and production aluminium profile

3.about 28-year experience of aluminium profile

4.Annual output reaches 30,000 tons .

5.30% of our products export to over seas country

6.business range of aluminium profiles:

# for window ,door ,fence , screen ,surtain wall ,handrail, partition ,wardrobe,ect

#indstrial profile ,such as solar panel frames, exhibit shelf ,LED Frames, prodoction factility, ect

#any size tube, pipe ,angle,T profile, U channel

7.Engineering design and consultant ,we can do the design according to your samples or drawings .

What kind of products and service we can provide:

♣aluminum profile for construction, such as doors, windows, fence, screen, curtain wall, handrail, partition, wardrobe, greenhouses and sunroom, etc

♣ industrial aluminum profile for solar energy, LED, machinery, advertisement, transport, auto part, exhibit shelf, telecom etc.

♣ doors and windows system, including sliding door, side hung window, tilt and turn window, etc.

♣ machining for aluminum and S/S products: cutting, drilling holes, punching, milling, de-burr, chamfer, stretch bending, welding and so on

♣ Stainless steel welded tubes

♣ Engineering design and consultant |

1) Alloy: 6063, 6061, 6060, 6005, 6463, etc.

2) Temper: T4, T5, T6

3) Certificate: ISO9001:2000

4) Series of surface treatment:

*Mill Finish

*Anodizing

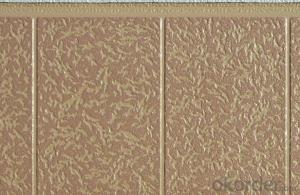

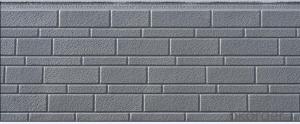

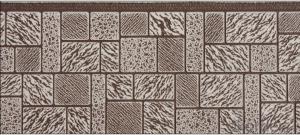

*Powder Coating

*Electrophoretic Coating

*Wood Grain(wood imitation)

*Thermal Break(heat insulation)

*Polish

5) Packing: Kraft paper, Pearl cotton foam, plastic film, or as the customer requires

6) Applications: windows, doors, curtain walls, cabinet, transportation, building, channel, railing, bracket, glasshouses, heat sinks, etc.

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Other |

Remain |

6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.4-0.6 |

0.1 |

0.1 |

0.15 |

Aluminum | |

6060 |

0.3-0.6 |

0.1-0.3 |

0.1 |

0.1 |

0.35-0.6 |

0.05 |

0.15 |

0.15 |

Aluminum | |

6061 |

0.4-0.8 |

0.7 |

0.15-0.4 |

0.15 |

0.8-1.2 |

0.04-0.35 |

0.25 |

0.15 |

Aluminum | |

6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.15 |

Aluminum |

Aluminum product requirement: | ||

Item |

Original Product |

Alternatives |

Standard for extrusion |

GB/T5237-2008

(Chinese national standard) |

EN-755-2/3/6/8,BS-1474.bs-1161(British standard)

JIS H4100(Japanese standard)

AS/NZS1866-1997(Australian Standard) |

Standard for anodizing |

GB5237.2-2008 |

BS1615:1987

BS5599:1993

Mil-A-8625E Type Ⅱ/Ⅲ |

Working /service procedure |

Die designing → die making → smelting & alloying→ extruding →cutting→ CNC → drilling → tapping→ surface treatment →welding→ assembling→ packing→ shipping→ after sales service | |

Quality oriented |

ISO 9001:2008 TS16949:2002 | |

Packing method |

1.standard packing: plastic sheet wrapped for each profile in order to protect the profiles’ surface, kraft paper wrapped in bundles

2.special packing: wooden cases + iron trays

3.bundles or boxes with wooden bars

4.EPE + carton boxes

5.customized packing methods are welcome | |

Loading weight |

20’GP for 13 tons, 40’ GP for 20 tons. LCL shipment will be acceptable. | |

- Q: What materials are required to be tested?

- Curtain wall works need to re-inspection materials The first is the keel material: channel, angle, some supervision also requires steel to be measured; followed by chemical anchor to do on-site drawing experiment, as if to do three groups; and then is the glass aluminum. Main profiles (including aluminum and steel profiles), screw bolts, drawing test, four-color inspection, hardware accessories The project is mainly hidden before the board, including steel keel, anti-corrosion operations, materials, such as inspection and other processes.

- Q: Aluminum alloy curtain wall profiles 130,140 series how much money a ton

- About twenty thousand dollars

- Q: Main wall thickness requirements greater than 1.4mm What is the meaning, as well as curtain wall.

- That is, the purchase of aluminum or other profiles to achieve the thickness of 1.4mm. In accordance with national standards, you ordered the profile or curtain wall is required 1.5mm, because the national standard plate 1.5mm minimum thickness of the negative tolerance of 01.38mm, basically can reach 1.4mm. If the procurement of 1.4mm profile curtain wall panels, the thickness is certainly less than 1.4mm. hope this helps!

- Q: Curtain wall aluminum is not broken bridge aluminum line okay

- Hidden curtain wall itself is the heat, the box wall is the existence of broken bridge insulation!

- Q: Hidden frame curtain wall, structural adhesive bonding surface treatment whether there is a standard?

- Structural silicone sealant for construction GB16776-2005 is specified.

- Q: What are the differences between aluminum oxide curtain wall materials and oxidation doors and windows? Is the thickness of the coating different?

- Aluminum alloy material, the thickness of the oxide film if there is no special requirements are the same. Just a curtain wall profile, one is the doors and windows profiles. Now the windows used in the works are broken bridge insulation profiles, even if they are oxidized materials, window profiles will be slightly more expensive than the curtain wall profile, more than a process, more than two insulation bars.

- Q: What are the glass curtain wall profiles? How to fix

- Glass curtain wall is widely used by modern buildings, so that this building is more transparent and sense of space, making the already beautiful building added a bit big momentum and contemporary atmosphere. Glass curtain wall heavy structure system can be divided into grid system and carbon plate system; from the installation method can be divided into briquetted, hanging and mosaic; from the vertical form can be divided into open frame glass curtain wall, semi-invisible Hengming vertical, vertical and horizontal), all-invisible glass curtain wall, hanging all-glass curtain wall, point-like all-glass curtain wall. For the performance of different architectural styles, the use of glass types are single glass, insulating glass, laminated glass, single-piece Rewan and spherical laminated Rewan glass to meet the different functional requirements and aesthetic requirements. Applicable to buildings with high lighting requirements such as hotels, office buildings and commercial, sports Expo buildings.

- Q: What are the insulation curtain wall aluminum profiles?

- Wear more common, that is, between the two ordinary aluminum profiles with two pieces of nylon material as a whole, nylon can transmit power at the same time can cut off the indoor and outdoor heat conduction, to achieve the purpose of saving

- Q: The offer is the construction side. All-inclusive, including aluminum alloy skeleton, artificial, glass and so on. Hurry.

- The cost of 700 yuan / square meter, if you offer generally in 800 yuan / ㎡

- Q: Full concealed glass curtain wall works, aluminum alloy column theoretical weight Column is 120 * 60 aluminum alloy beam is 60 * 60, the material is 6063-T5, the drawings do not have the standard thickness, the theoretical weight is how much,

- This problem I encountered, you get the drawings also need to deepen the design, especially the aluminum alloy profiles, depends on what brand you and what series, each brand will have its own profile, such as 120 profiles, cross-section will There are many forms of your company to choose, different cross-section manufacturers will give the weight of the profile is how much, so you will be accurate, this is not like a steel weight of the theoretical weight, the current curtain wall profiles more , Each have electronic or paper profiles, if you are the construction unit, of course, to choose to meet the original requirements of the drawings and the lightest weight of the profile

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 1999 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; Eastern Europe; Southeast Asia; Africa; Eastern Asia; South Asia; Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shunde,Huangpu,Shenzhen |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Shampagn Powder Coated Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 25,000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords