Powder Coated Aluminum Alloy Cold Rolled Sheets with Best Price

- Loading Port:

- Shanghai

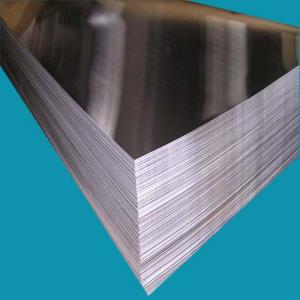

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

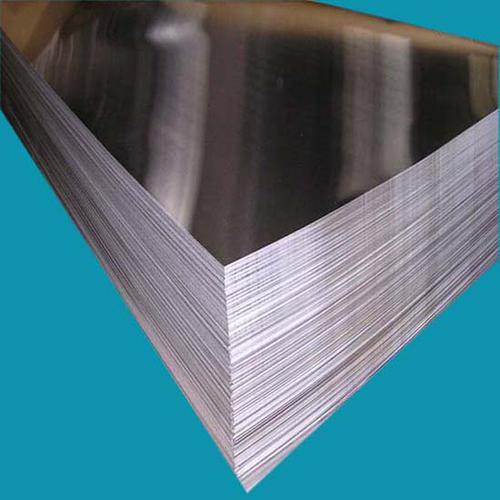

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What are the common sizes of aluminum sheets?

- The common sizes of aluminum sheets vary, but some of the standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely available and commonly used in various industries.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Indeed, automotive body panels can be manufactured using aluminum sheets. Aluminum, being a material that is both lightweight and robust, presents numerous advantages in the realm of automotive applications. Its high ratio of strength to weight enables enhanced fuel efficiency and superior overall vehicle performance. Furthermore, aluminum boasts exceptional corrosion resistance, rendering it suitable for enduring adverse environmental conditions. Moreover, its malleability and ease of manipulation facilitate the creation of intricate designs and shapes essential for automotive body panels. These attributes have established aluminum sheets as a highly favored option within the automotive industry for the production of body panels.

- Q: Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- That's a good question, I was wondering the same thing myself

- Q: Can aluminum sheets be used for automotive body panels?

- Yes, aluminum sheets can be used for automotive body panels. Aluminum is lightweight, strong, and resistant to corrosion, making it a suitable material for constructing car body panels. Its use can help reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it a popular choice for various aerospace applications. It is commonly used in the construction of aircraft structures, such as fuselages, wings, and panels. The use of aluminum sheets in the aerospace industry offers several benefits, including reduced fuel consumption due to the weight savings, improved maneuverability, and increased payload capacity. Additionally, aluminum exhibits good corrosion resistance, which is crucial for aircraft exposed to harsh environmental conditions. Overall, aluminum sheets are widely utilized in the aerospace industry for their favorable properties and performance.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- You should set this project aside. Ignore my advice? You're on track for a Darwin Award. You win!

- Q: What are the different methods of surface etching aluminum sheets?

- There are several methods of surface etching aluminum sheets, including chemical etching, electrochemical etching, mechanical etching, and laser etching. Chemical etching involves the use of corrosive chemicals to selectively remove the surface material, creating a desired pattern or design. Electrochemical etching uses an electrical current to dissolve the surface of the aluminum sheet, also creating a pattern. Mechanical etching involves physically abrading the surface using tools or abrasive materials. Laser etching utilizes a high-powered laser beam to selectively remove the aluminum material, creating precise and detailed patterns.

- Q: Can aluminum sheets be used for insulation jackets?

- Indeed, insulation jackets can indeed employ aluminum sheets. Aluminum possesses exceptional thermal conductivity characteristics, enabling it to proficiently deflect heat and hinder the transmission of thermal energy. Consequently, it becomes the perfect substance for insulation jackets, as it aids in preserving temperature regulation and reducing heat loss or gain. Furthermore, aluminum sheets are lightweight, long-lasting, and impervious to corrosion, rendering them a pragmatic option for insulation applications.

- Q: Aluminum plate belongs to steel or non ferrous metal?

- Metal materials fall into two broad categories: ferrous and non-ferrous metals. What we usually call "iron and steel" is ferrous metal; copper and aluminum are nonferrous metals.

Send your message to us

Powder Coated Aluminum Alloy Cold Rolled Sheets with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords