Aluminum Alloy Extrusion Profiles for Window Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

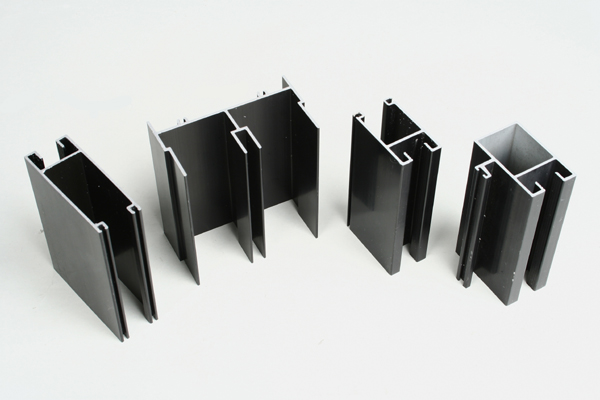

Aluminium Profile For windows

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the different machining techniques used on aluminum profiles?

- Some of the different machining techniques used on aluminum profiles include milling, drilling, turning, grinding, and tapping. These processes help shape and refine the aluminum profiles to meet specific design requirements and achieve desired dimensions and surface finishes.

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can definitely be used for modular storage systems. Aluminum is a lightweight yet sturdy material that is commonly used in various industries for its durability and versatility. It is particularly well-suited for modular storage systems due to its ability to be easily cut, shaped, and joined together. Aluminum profiles provide a great solution for creating customized storage units that can be easily adjusted or expanded as needed. They can be used to build shelving systems, cabinets, drawers, and other storage components. The modular design allows for easy assembly and disassembly, making it convenient to rearrange or reconfigure the storage system whenever required. Furthermore, aluminum profiles offer excellent corrosion resistance, ensuring that the storage system will remain in good condition even in harsh environments. They are also available in a variety of finishes, allowing for customization to match the desired aesthetic or design requirements. Overall, aluminum profiles provide a cost-effective and durable solution for modular storage systems, offering flexibility, ease of use, and long-lasting performance.

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Domestic aluminum quality is about the same, mainly you installed in the window accessories, is the key to the life of the service, recommend several brands Bar Reid Jan Ron Lixin spring is not recommended, quality is not very rely on live

- Q: What are the different colors and finishes available for aluminum profiles?

- Aluminum profiles offer a wide array of colors and finishes for customization and design versatility. The available options include anodized finishes, which involve creating a durable oxide layer through an electrochemical process. This not only provides color choices like silver, black, white, bronze, and gold but also enhances corrosion resistance and durability. In addition to anodizing, powder coating is a popular method for achieving different colors and finishes. It involves applying a dry powder electrostatically and then heat-curing it for a smooth, strong, and uniform result. This technique offers a broad range of colors, including metallic, matte, gloss, and textured finishes. Moreover, liquid paint can also be utilized to paint aluminum profiles, offering limitless color possibilities. This makes it perfect for projects with unique design requirements, as the finishes can be customized to match specific color needs. To summarize, aluminum profiles can be finished with anodized options like silver, black, white, bronze, and gold, as well as powder coating finishes such as metallic, matte, gloss, and textured. Additionally, liquid paint allows for virtually any desired color. These choices ensure design flexibility and enable aluminum profiles to complement various architectural and industrial applications.

- Q: Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material for window frames due to its lightweight, strength, and durability. It is resistant to corrosion, so it is ideal for windows in coastal areas or places with high humidity. Aluminum frames also offer a sleek and modern appearance that complements various architectural styles. Additionally, aluminum is a sustainable material as it can be recycled, making it an environmentally friendly choice for window frames.

- Q: Are aluminum profiles suitable for high-temperature environments?

- Aluminum profiles are generally unsuitable for environments with high temperatures. Despite its excellent thermal conductivity and lightweight nature, aluminum has a lower melting point compared to other metals. At temperatures exceeding 400°C (752°F), aluminum begins to soften and can eventually lose its structural integrity. In high-temperature surroundings, aluminum profiles can experience deformation, distortion, or even complete failure. This can jeopardize the stability and functionality of any structure or system relying on aluminum profiles. Nevertheless, there exist specific aluminum alloys that are specifically engineered to withstand higher temperatures. Alloys like 6061 and 7075 have enhanced heat resistance and can endure higher temperatures without significant damage. These specialized alloys are commonly employed in applications requiring resistance to elevated temperatures, such as aerospace components or certain industrial processes. However, it is essential to thoroughly evaluate the temperature requirements of a given environment before utilizing aluminum profiles. In extremely high-temperature settings, alternative materials like steel or refractory metals may be more appropriate due to their higher melting points and superior heat resistance properties.

- Q: This question is asking about the various types of aluminum profiles that are used for exterior cladding purposes.

- <p>Aluminum profiles for exterior cladding are diverse and serve various architectural and functional needs. Some common types include: 1. Flat Profiles: Used for simple, sleek designs. 2. Box Profiles: Ideal for creating a modern, industrial look. 3. Angle Profiles: Useful for corners and edges. 4. Channel Profiles: Often used for window and door frames. 5. T-Profiles: Commonly used for hidden fastening systems. 6. U-Channels: Suitable for cover applications. 7. Special Profiles: Custom designs for specific architectural requirements. Each type offers unique benefits in terms of aesthetics, strength, and weather resistance, making them suitable for different building facades and exterior applications.</p>

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can follow these simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum profiles using a soft brush or cloth. 2. Prepare a cleaning solution by mixing mild dish soap or a non-abrasive cleaner with warm water. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum profiles. Be sure to clean all the corners and crevices thoroughly. 4. Rinse the profiles with clean water to remove any soap residue. You can use a hose or a bucket of water for this step. 5. Dry the aluminum profiles completely using a soft, lint-free cloth. This will prevent water spots or streaks from forming. 6. For regular maintenance, you can use a specialized aluminum cleaner or polish to restore the shine and protect the surface. Follow the instructions on the product for best results. 7. It is important to avoid using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Also, never use acidic cleaners or vinegar on aluminum as they can cause corrosion. 8. If you notice any scratches or minor damages on the aluminum profiles, you can use a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Remember, regular cleaning and maintenance will help preserve the appearance and longevity of your aluminum profiles.

- Q: How do you calculate the strength of aluminum profiles?

- To calculate the strength of aluminum profiles, there are several factors that need to be considered. 1. Material properties: The first step is to know the mechanical properties of the aluminum alloy being used, such as its yield strength, ultimate tensile strength, and elastic modulus. These properties can be obtained from material data sheets or testing. 2. Cross-sectional area: The next step is to determine the cross-sectional area of the aluminum profile. This can be done by measuring the dimensions of the profile or referring to its specifications. The cross-sectional area is typically calculated by multiplying the width and height of the profile. 3. Load calculation: Once the cross-sectional area is known, the next step is to calculate the applied load on the profile. This can be determined by considering the weight or force that will be acting on the profile. The load can be static or dynamic, and it is important to account for any potential variations or impacts. 4. Stress analysis: With the load and cross-sectional area determined, the stress on the aluminum profile can be calculated using the formula: Stress = Load / Cross-sectional area. This will give the stress value in units of force per unit area (e.g., N/m2 or psi). 5. Safety factor: To ensure the profile's strength is adequate, a safety factor is typically applied. The safety factor accounts for uncertainties in the load calculations and ensures the profile can handle unexpected loads or variations. Common safety factors range from 1.5 to 4, depending on the specific application and industry standards. By considering these factors and performing the necessary calculations, it is possible to determine the strength of aluminum profiles and ensure they meet the required safety standards for their intended applications.

Send your message to us

Aluminum Alloy Extrusion Profiles for Window Aluminium Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords