Aluminum Extruded Profiles for Windows and Doors Frame - Aluminum Alloy Profile Extrusion Wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Application of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

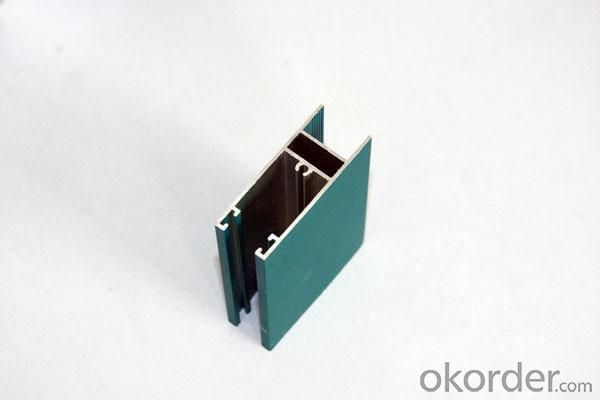

5. Image of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

6. Package and shipping of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do aluminum profiles perform in load-bearing structures?

- Aluminum profiles perform well in load-bearing structures due to their high strength-to-weight ratio. They are lightweight, yet highly durable and resistant to corrosion. Additionally, aluminum profiles can be easily fabricated and customized to meet specific design requirements, making them an ideal choice for various load-bearing applications such as bridges, buildings, and aerospace structures.

- Q: Can aluminum profiles be used in swimming pool enclosures or structures?

- Yes, aluminum profiles can be used in swimming pool enclosures or structures. Aluminum is a lightweight and corrosion-resistant material that is commonly used in construction projects, including swimming pool enclosures. Its durability and strength make it an ideal choice for withstanding the harsh pool environment, providing a long-lasting and aesthetically pleasing solution.

- Q: What are the different tolerance levels for aluminum profiles?

- The tolerance levels for aluminum profiles can vary depending on the specific requirements and applications. Generally, aluminum profiles have tight tolerance levels due to their importance in various industries such as automotive, aerospace, and construction. The most common tolerance levels for aluminum profiles include dimensional tolerances, straightness tolerances, and surface finish tolerances. Dimensional tolerances refer to the permissible deviation from the specified measurements of the profile. These tolerances ensure that the profile meets the required dimensions and can fit properly in the intended application. The dimensional tolerances for aluminum profiles are typically specified in terms of millimeters or inches. Straightness tolerances determine the allowable deviation from a perfectly straight line for the aluminum profile. This tolerance ensures that the profile is not bent or warped, which is crucial for maintaining structural integrity and accurate assembly. Surface finish tolerances define the acceptable level of imperfections on the surface of the aluminum profile. These imperfections can include scratches, indentations, or roughness. The surface finish tolerance is typically specified in terms of roughness average (Ra) or surface quality codes, such as anodized or powder-coated finishes. It is important to note that the specific tolerance levels for aluminum profiles can vary depending on the manufacturing process, the intended application, and the industry standards. Therefore, it is essential to consult the relevant specifications, industry standards, or the supplier's guidelines to determine the precise tolerance levels for a specific aluminum profile.

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: What is a pouring type heat insulation aluminum profile?

- The utility model has the advantages of compact structure, artful appearance, lighting area, high strength of the profile, high heat insulation property, high material ratio and aluminum saving.

- Q: Are aluminum profiles suitable for use in the telecommunications industry?

- Yes, aluminum profiles are suitable for use in the telecommunications industry. Aluminum profiles offer a lightweight and durable solution for various applications in the telecommunications field, such as antenna mounts, equipment racks, enclosures, and cable management systems. They offer excellent corrosion resistance, thermal conductivity, and electromagnetic shielding properties, making them a reliable choice for supporting and protecting telecommunications equipment. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, making them highly versatile for use in the telecommunications industry.

- Q: What are the different sizes and dimensions of aluminum profiles?

- The different sizes and dimensions of aluminum profiles can vary greatly depending on the specific application and manufacturer. They can range from small, narrow profiles with dimensions of a few millimeters to larger, wider profiles with dimensions of several inches or more. The length of the profiles can also vary, typically ranging from a few feet to several meters.

- Q: What are the methods to protect aluminum profiles from corrosion during the installation and usage phases?

- <p>To prevent corrosion of aluminum profiles during installation and use, follow these steps: 1. Choose high-quality aluminum profiles with proper alloy composition that resists corrosion. 2. Ensure the surface is clean and free from contaminants before installation. 3. Apply a protective coating such as a clear anodized finish, powder coating, or paint to the aluminum surface. 4. Avoid contact with corrosive substances like saltwater or chemicals. 5. Regularly inspect and clean the profiles to remove dirt and debris that can lead to corrosion. 6. Use stainless steel fasteners and avoid dissimilar metal contact, as it can accelerate corrosion. 7. Maintain a dry environment to prevent moisture-induced corrosion. By following these practices, you can significantly reduce the risk of corrosion and prolong the lifespan of aluminum profiles.</p>

- Q: Are aluminum profiles easy to install?

- Aluminum profiles, in general, have a reputation for being easy to install. Their lightweight nature and manipulability contribute to a simpler installation process when compared to alternative materials. Moreover, aluminum profiles frequently come equipped with pre-drilled holes or slots, which aid in installation and guarantee precise alignment. Additionally, the modular design of aluminum profiles permits effortless assembly and disassembly without any requirement for specialized tools or expertise. All in all, the user-friendly characteristics of aluminum profiles make them a favored option for a wide range of applications, including construction, manufacturing, and DIY projects.

Send your message to us

Aluminum Extruded Profiles for Windows and Doors Frame - Aluminum Alloy Profile Extrusion Wholesale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords