China Aluminum Alloy Extrusion Profiles for Aluminium Profile Anodizing for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile Anodizing for Windows and Doors Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Anodizing for Windows and Doors:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

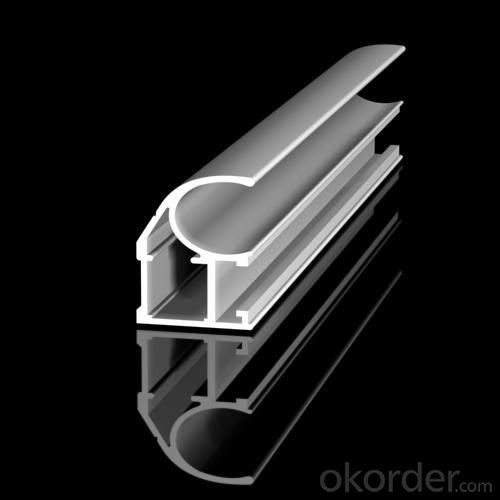

Images of the Aluminium Profile Anodizing for Windows and Doors:

Aluminium Profile Anodizing for Windows and Doors Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Indeed, amusement park rides can be constructed using aluminum profiles. Aluminum is a favored material for building different parts of amusement park rides because of its lightweight nature and durability. The profiles can be effortlessly molded and joined together to form intricate structures like roller coaster tracks, supports, and frames for other rides. Moreover, aluminum's resistance to corrosion makes it suitable for outdoor settings where the rides are subjected to weather conditions. Furthermore, aluminum is an environmentally friendly option for amusement park ride construction as it can be recycled, showcasing its sustainability. In conclusion, aluminum profiles offer a flexible and dependable choice for creating secure and thrilling amusement park rides.

- Q: How to prevent the aging of aluminum profile hardness is not enough?

- When the time limit is guaranteed, the process is executed without overheating and time is guaranteed.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: Are aluminum profiles suitable for use in medical device manufacturing?

- Yes, aluminum profiles are suitable for use in medical device manufacturing. Aluminum is a lightweight and durable material that offers excellent mechanical properties, corrosion resistance, and versatility. It can be easily machined and formed into various shapes, making it ideal for creating custom components for medical devices. Additionally, aluminum profiles can be anodized or coated to further enhance their surface properties, ensuring compatibility with medical environments.

- Q: How do aluminum profiles contribute to sustainable building practices?

- There are several reasons why aluminum profiles are crucial in promoting sustainable building practices. To begin with, aluminum is a material that can be recycled multiple times without any loss in quality. This recyclability significantly reduces the need for extracting and processing new aluminum, which is a process that consumes a lot of energy and harms the environment. By using aluminum profiles in construction, we can greatly reduce the demand for new aluminum production and thus conserve natural resources and decrease carbon emissions. In addition, aluminum profiles are both lightweight and strong, making them ideal for creating energy-efficient structures. Their lightweight nature reduces the load on the building's foundation and structural elements, resulting in lower material requirements and reduced construction costs. Furthermore, a lighter structure requires less energy for heating and cooling, leading to decreased energy consumption and reduced greenhouse gas emissions throughout the building's lifespan. Moreover, aluminum profiles have excellent thermal and acoustic insulation properties. When used correctly, they can contribute to the overall energy efficiency of a building by minimizing heat loss or gain through windows and doors. This means that less reliance is placed on artificial heating and cooling systems, resulting in decreased energy consumption and lower utility bills. Another advantage of aluminum profiles is their durability and low maintenance requirements. They are resistant to corrosion, weathering, and UV rays, which ensures a long lifespan and reduces the need for frequent replacements and repairs. This not only saves resources but also reduces waste generation and the use of landfills. Finally, aluminum profiles offer great design flexibility and can be easily incorporated into various architectural styles and designs. This versatility allows architects and builders to create structures that are both visually appealing and functional, while still adhering to sustainable building practices. In conclusion, aluminum profiles contribute to sustainable building practices by being recyclable, lightweight, energy-efficient, thermally insulating, durable, low maintenance, and versatile. By using aluminum profiles in construction projects, we can reduce our environmental impact, conserve natural resources, and promote a more sustainable future.

- Q: Can aluminum profiles be used in electrical enclosure manufacturing?

- Yes, aluminum profiles can be used in electrical enclosure manufacturing. Aluminum is a versatile and lightweight material that offers excellent electrical conductivity, heat dissipation, and corrosion resistance. It can be easily shaped into different profiles to suit specific enclosure designs and can provide adequate protection for electrical components.

- Q: Can aluminum profiles be used in modular exhibition system manufacturing?

- Yes, aluminum profiles can be used in modular exhibition system manufacturing. Aluminum profiles are lightweight, durable, and easy to work with, making them a popular choice for constructing modular exhibition systems. They can be easily customized and assembled to create various shapes and configurations, providing flexibility and versatility in exhibition designs. Additionally, aluminum profiles offer a sleek and professional appearance, enhancing the overall aesthetics of the exhibition system.

- Q: This question seeks to understand the methods used to prevent rust and corrosion on aluminum profiles.

- <p>To prevent aluminum profiles from rusting and corroding, several methods can be employed: 1) Anodizing: This process creates a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion. 2) Powder Coating: Applying a durable powder coating can protect the aluminum from moisture and other corrosive elements. 3) Regular Cleaning: Regularly cleaning the aluminum profiles can remove dirt and debris that may lead to corrosion. 4) Protective Films: Applying protective films or tapes can shield the aluminum from environmental factors that cause corrosion. 5) Proper Storage: Storing aluminum profiles in a dry, well-ventilated area can prevent moisture accumulation, which is a leading cause of rust. 6) Use of Corrosion Inhibitors: Applying corrosion inhibitors can slow down or prevent the chemical reactions that lead to corrosion. By implementing these measures, the lifespan and integrity of aluminum profiles can be significantly improved.</p>

- Q: What industries commonly use aluminum profiles?

- Aluminum profiles find wide applications in various industries, owing to their unique properties and versatility. The construction industry is one of the major sectors that extensively employs aluminum profiles. These profiles are utilized in the construction of windows, doors, curtain walls, and other architectural components. The lightweight nature of aluminum makes it an ideal preference for such applications, as it reduces the burden on the building structure. Similarly, the automotive industry heavily relies on aluminum profiles for manufacturing purposes. These profiles are used in the production of car frames, body panels, and components, offering an exceptional strength-to-weight ratio and corrosion resistance. By incorporating aluminum profiles, the overall weight of vehicles is reduced, resulting in improved fuel efficiency and performance. Aerospace manufacturing is another sector that heavily depends on aluminum profiles. These profiles are employed in constructing aircraft frames, wings, and fuselages. Their high strength and durability make them suitable for enduring the challenges of flight, while their lightweight characteristic contributes to fuel efficiency. The electronics industry also finds great utility in aluminum profiles. They are used in the production of heat sinks, aiding in the dissipation of heat from electronic components. Aluminum's excellent thermal conductivity ensures effective heat transfer, safeguarding sensitive electronic devices from damage. Furthermore, the furniture industry adopts aluminum profiles extensively in the production of lightweight and durable furniture pieces. These profiles are used to construct frames for chairs, tables, shelves, and various other furniture items. Their corrosion resistance and aesthetic appeal make them a preferred choice for both indoor and outdoor furniture. In conclusion, industries such as construction, automotive, aerospace, electronics, and furniture commonly embrace aluminum profiles due to their lightweight nature, strength, corrosion resistance, and versatility. These profiles play a vital role in enhancing the performance, efficiency, and durability of products in these industries.

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

Send your message to us

China Aluminum Alloy Extrusion Profiles for Aluminium Profile Anodizing for Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords