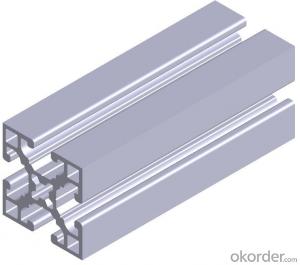

Aluminum Alloy Curtain Wall Corner Profile for Sliding Screen Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Curtain wall corner profile

1. Surface: Mill surface treatment or others.

2. Alloy: AA6063-T6 ,

3. Size:various dimensions in order to meet customer’s requirement

4. Physical Performance: Aluminium does not suffer badly from corrosion and is easy to form and finish allowing many different designs. Aluminium is used as hollow sections and is relatively flexible in bending and torsion. Hardware often has to be matched against a particular profile. Because of the hollow and complex profile cross sections achievable with aluminium it is easy to make drained and ventilated or pressure equalised windows. Aluminium is a very good conductor of heat. To meet requirements for low thermal transmission aluminium profiles are thermally broken with either a polyamide or resin element between inner and outer aluminium sections. The latest proposals for improving the thermal performance of windows will require improved thermal breaks. Aluminium is the most common frame material for stick system curtain walls, glazing screens and shop fronts. It is also commonly used as a framing system to support rainscreens.

5. Alloy advantage: The alloy temper with 6063T6 which allows this structure to maintain good formability, good weldability, high hardness, good workability and good interface characteristics. Easy processing, easy coating and good corrosion resistance, oxidation resistance.

6. Package: Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

7. Life Time: Last for 50 years

8. Standard: EN755-9 standard

- Q: Are aluminum profiles suitable for roofing systems that need to withstand strong wind loads?

- <p>Yes, aluminum profiles can be used for roofing systems that require high levels of wind load resistance. Aluminum is a lightweight yet strong material with excellent resistance to corrosion and weathering. It can be engineered into profiles that provide the necessary structural integrity to withstand high wind loads. The flexibility of aluminum allows for the creation of various shapes and designs that can be tailored to meet specific wind resistance requirements. Additionally, aluminum's durability and low maintenance make it a popular choice for roofing systems in areas prone to high winds.</p>

- Q: What are the different surface etching options for aluminum profiles?

- Some different surface etching options for aluminum profiles include chemical etching, mechanical etching, and laser etching. Chemical etching involves using a chemical solution to remove layers of the aluminum surface, creating a desired pattern or texture. Mechanical etching involves using abrasive materials or tools to physically remove material from the surface. Laser etching uses a laser beam to selectively remove material from the surface, creating precise and intricate designs.

- Q: How can I distinguish aluminum from aluminium oxide or electrophoresis aluminum or spray aluminium material?

- Spraying aluminum can also increase the thickness of aluminum, but it can be observed under the magnifying glass. The coating on the surface of the electrophoresis aluminum is more dense and tidy

- Q: Is it possible to utilize aluminum profiles as part of the exterior cladding systems for commercial buildings?

- <p>Yes, aluminum profiles are commonly used for exterior cladding systems in commercial buildings. They offer several advantages such as durability, resistance to weather and corrosion, low maintenance, and a modern aesthetic. Aluminum's lightweight nature and strength make it an ideal material for cladding, and it can be easily shaped and joined to create a variety of designs. Additionally, aluminum profiles can be coated or anodized to provide color and further protection against the elements.</p>

- Q: What does aluminum 6063 T5 mean?

- 6063 is a kind of 6 alloy, T5 is quenched, air-cooled

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: Are there any fire safety considerations when using aluminum profiles?

- Yes, there are fire safety considerations when using aluminum profiles. Although aluminum itself is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, especially when used in construction or industrial applications, can act as fuel for a fire and potentially increase its severity. One important consideration is the fire rating of the aluminum profiles. Fire ratings indicate the length of time a material can withstand exposure to fire before it fails. It is crucial to select aluminum profiles with appropriate fire ratings that align with the specific requirements of the application. This ensures that the profiles can delay the spread of fire, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of appropriate insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In such cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This helps prevent the fire from spreading through the building envelope and reduces the risk of structural failure. Additionally, fire safety measures should be implemented during the installation process. Proper firestopping techniques should be employed to seal any gaps or penetrations around the aluminum profiles. This helps prevent the passage of flames, smoke, and hot gases from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also essential for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, proper fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, while aluminum profiles themselves may not be combustible, it is important to consider various fire safety measures when using them in construction or industrial applications. By selecting appropriate fire-rated profiles, using fire-resistant insulation materials, implementing proper installation techniques, and maintaining regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q: What role does glass curtain wall aluminum profile holder play?

- The subframe is formed by connecting the silicone structural adhesive with the glass and then connecting the plate with the aluminum alloy through the platen. The purpose of the subframe is to achieve the "hidden frame" purpose

- Q: How do aluminum profiles perform in thermal insulation applications?

- Aluminum profiles are not typically renowned for their exceptional thermal insulation properties. Nonetheless, with the aid of supplementary measures, they can still be effectively employed in thermal insulation applications. Aluminum, being a highly conductive material, readily conducts heat. Consequently, there can be substantial heat transfer between the interior and exterior of a building, resulting in energy loss and decreased thermal efficiency. Thus, aluminum profiles alone may not offer adequate insulation. To enhance the thermal insulation performance of aluminum profiles, multiple strategies can be utilized. One prevalent approach involves the utilization of thermal breaks or barriers. These insulating elements are positioned between the outer and inner aluminum sections to minimize heat transfer. Thermal breaks can be composed of materials with low thermal conductivity, such as polyamide or polyurethane. Another technique is the incorporation of double or triple glazing in windows and doors. By integrating multiple layers of glass with an interstitial gap, the insulating properties are substantially enhanced, thereby reducing heat transfer through the aluminum frames. Furthermore, the application of low-emissivity (low-e) coatings on the glass surfaces can further augment the thermal insulation performance. These coatings reflect heat back into the interior while permitting visible light to pass through, resulting in improved energy efficiency. In conclusion, although aluminum profiles possess inherent limitations in terms of thermal insulation, they can still be effectively utilized in thermal insulation applications by incorporating thermal breaks, double or triple glazing, and low-e coatings. These measures aid in minimizing heat transfer and enhancing energy efficiency, rendering aluminum profiles suitable for various types of buildings.

- Q: How about the price of aluminum profile?

- Aluminum prices are calculated according to the price of aluminum ingot + processing fees, such as: aluminum ingot price 16000+, processing fee 6000 = 22000 yuan / ton

Send your message to us

Aluminum Alloy Curtain Wall Corner Profile for Sliding Screen Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords