Aluminium Profile Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

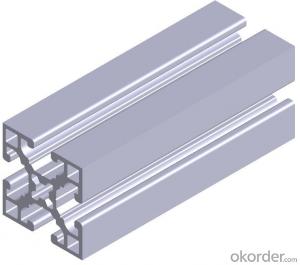

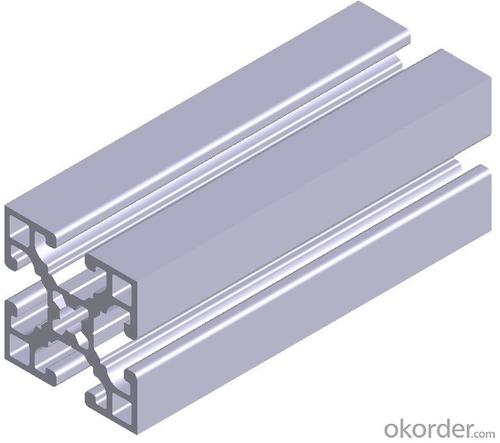

Structure of Aluminium Profile Curtain Wall Application Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Curtain Wall Application:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

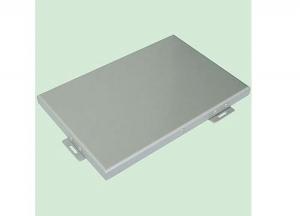

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminium Profile Curtain Wall Application:

Aluminium Profile Curtain Wall Application Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- 4500T is not very large extrusion machine, a little aluminum factory are generally, in the hope of Liaoning, Qinghai Guoxin, Yun ore has more than 10000 tons of production lines, more than sixty percent domestic aluminum production is Guangdong Foshan, there are several manufacturers have the production line, such as Albert, Jianmei so, need to understand the aluminum things to find the best side to understand

- Q: How do aluminum profiles perform in seismic or earthquake-prone areas?

- The unique properties of aluminum profiles have been shown to be highly effective in areas with seismic or earthquake risks. The lightweight nature of aluminum is a popular choice for construction in these areas because it reduces the overall weight of the structure, minimizing the potential for collapse during an earthquake. In addition, aluminum has excellent ductility, allowing it to deform under stress without fracturing. This quality enables it to absorb and dissipate the energy generated by seismic activity. Moreover, aluminum profiles have a high strength-to-weight ratio, making them able to withstand the dynamic forces exerted during an earthquake. This strength, combined with the material's resistance to corrosion, makes aluminum profiles particularly suitable for seismic areas where the risk of structural damage is higher. Furthermore, aluminum is highly malleable, making it easy to shape and fabricate into various structural components. This flexibility allows for the creation of customized designs that can withstand seismic forces. Additionally, aluminum profiles can be easily connected through bolting or welding, providing a secure and reliable connection that further enhances the building's structural integrity. It is important to note that the performance of aluminum profiles in seismic areas also relies on the overall design and construction techniques used. Incorporating seismic bracing systems or using specialized connectors are proper engineering practices that can further improve the performance of aluminum structures during earthquakes. Overall, due to its lightweight, ductile, strong, and corrosion-resistant properties, aluminum has proven to be a reliable and effective material for use in seismic or earthquake-prone areas. When properly designed and constructed, aluminum profiles can significantly enhance the safety and resilience of structures in these challenging environments.

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: What are the different surface protection coatings for aluminum profiles?

- Some of the different surface protection coatings for aluminum profiles include anodizing, powder coating, painting, and electroplating. Anodizing forms a protective oxide layer on the surface, while powder coating and painting provide a durable and decorative finish. Electroplating involves depositing a thin layer of metal onto the surface to enhance its corrosion resistance.

- Q: What is the HS code for aluminum profile?

- There are 76072000 aluminum foil backing76081000 pure aluminum tubeTubular Aluminum Alloy 76082010.099999994 cm diameter less than or equal to 10The other 76082010.900000006 aluminum alloy outer diameter less than 10 cm.76082099.099999994 outside diameter > 10 cm, other tubular aluminium alloy76082099.900000006 outside diameter > 10 cm, other alloy aluminium tube76090000 aluminum pipe fittings76101000 aluminum doors and windows and their frames, thresholds76109000 other aluminum structures and their components76110000 volume > 300 litre aluminium bin, pot and other containers76121000 aluminium hose container76129010 aluminum cans and cansThe store, tank 76129090 volume less than 300 liters76130010 retail packaging aluminium containers for compressed and liquefied gases76130090 non retail retail containers for compressed and liquefied gases76141000 strand aluminum stranded wire, cable, braid76149000 aluminium stranded wire, cable, braid without strip core76151900.099999994 aluminum pressure cooker76151900.900000006 other household utensils such as dining table and kitchen and their aluminium appliances76152000 aluminium sanitary ware and parts76161000 aluminum nails, screws, nuts, washers and other fastenersCloth, mesh, fence and grille 76169100 aluminum wire76169910.099999994 cylindrical solid aluminum alloy with a height of less than76169910.900000006 other industrial aluminum products76169990 other non industrial aluminum products84413010 plastic aluminum composite tank production equipment84418010 make paper plastic aluminum flexible packing equipment84552290.099999994 aluminum foil roughing mill85322210 piece aluminum electrolytic capacitor85322290 other aluminum electrolytic capacitors

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: This question asks for a list of various aluminum profiles that are utilized in the construction of building facades and cladding systems.

- <p>Aluminum profiles for facades and cladding systems come in various types, each serving specific purposes in construction. Common types include: 1. <strong>Aluminum Extrusions</strong>: Used for structural support and can be customized for specific design requirements. 2. <strong>Aluminum Channels</strong>: Often used for attaching panels or as a part of the support structure. 3. <strong>Aluminum Angles</strong>: Provide corner support and reinforcement. 4. <strong>Aluminum Flat Bars</strong>: Used for horizontal or vertical support in facade systems. 5. <strong>Aluminum Tubes</strong>: Can be used as a decorative element or for structural reinforcement. 6. <strong>Aluminum Louvers</strong>: Designed for sun shading and ventilation. 7. <strong>Aluminum Panels</strong>: Can be flat or profiled, used for the outer layer of the facade. 8. <strong>Aluminum Trims and Mouldings</strong>: Used for finishing and detailing around windows, doors, and edges. Each type is chosen based on the architectural design, structural requirements, and aesthetic preferences.</p>

- Q: Can aluminum profiles be used for display systems?

- Certainly, display systems can indeed make use of aluminum profiles. The lightweight and sturdy characteristics of aluminum make it a popular option for such systems. Its versatility allows for easy customization to meet the specific needs of the display system. Frames, shelves, stands, and other components of the display system can all be created using aluminum profiles. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor display applications. Furthermore, they provide a sleek and contemporary aesthetic, enhancing the visual appeal of the display system. In conclusion, aluminum profiles are a trustworthy and effective choice when designing and constructing display systems.

- Q: Is it possible to utilize aluminum profiles as a component in systems designed for covering interior walls?

- <p>Yes, aluminum profiles can be used for interior wall cladding systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. Aluminum profiles are easy to install and can be used in conjunction with various materials such as glass, stone, or wood to create a sleek and modern look. They are also customizable, allowing for a wide range of design options and can be powder-coated or anodized for different finishes and colors to match any interior design scheme.</p>

- Q: Are aluminum profiles recyclable?

- Yes, aluminum profiles are recyclable. Aluminum is a highly recyclable material, meaning it can be melted down and reused multiple times without losing its quality. Aluminum profiles, which are used in various applications such as construction, transportation, and manufacturing, can be easily recycled by collecting them from end-of-life products or scrap material and sending them to a recycling facility. The recycling process involves shredding the aluminum profiles into small pieces, removing any impurities, melting the aluminum, and then casting it into new profiles or other aluminum products. Recycling aluminum profiles helps to conserve natural resources, reduce energy consumption, and minimize environmental impact compared to producing new aluminum from raw materials.

Send your message to us

Aluminium Profile Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords