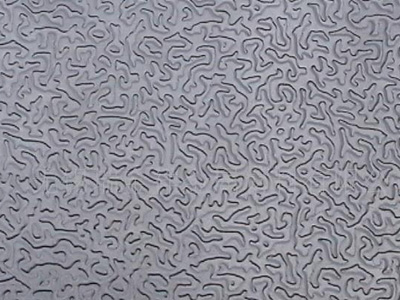

aluminium stucco sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum Stucco Embossed Sheet

1)1050/1060/1100

2)MOQ:6 Metric tons

3)300 tons sells per month

4)About 25 days of delivery

Stucco Aluminium Embossed Sheet

1.Description of Stucco Embossed Aluminium Sheet

Description | Embossed Aluminum Sheet/Coil |

Alloy | 1050; 1060;1100 ;3003; 3004;3105;5052; 6061; 6063 |

Temper | O; H18; H24; H32; H112 |

Thickness (MM) | 0.5-3.0 |

Width (MM) | 300~1600 |

Length (MM) | ≤8000 |

Application | Construction, Decoration, Automobile, Electronics, Machinery, Boat Construction, Aeronautics&Astronautics, Etc. |

2.The advantage of our Stucco Embossed Aluminium Sheet

(1) As aluminium is both a stable and durable material, it provides excellent service as a roofing or cladding without the need of any protective coating.

(2) The changes in appearance will be consistent along an elevation.

(3) Acid-corrosion-resistance, long-lasting shine, beautiful patterns, anti-corrosion performance and stability, strong adhesion, impact resistance, non-toxic side effects, safety and environmental protection.

(4) The electro-oxidation can effectively remove residual oil and manual handling of fingerprints.

(5) Embossed finish can enhance the thickness and strength of aluminum.

- Q: I want to use one aluminum bottle, rather than several plastic ones. And this may sound stupid, but will an aluminum water bottle be safe to put in the fridge?

- Water Bottle Fridge

- Q: How is aluminum sheet made?

- Aluminum sheet is made through a process called rolling, where a large aluminum ingot is passed through a series of rollers that gradually reduce the thickness of the metal until it reaches the desired sheet thickness. This process helps to improve the strength, flexibility, and surface finish of the aluminum sheet.

- Q: What is the fatigue strength of 101 aluminum sheets?

- The fatigue strength of 101 aluminum sheets refers to their ability to withstand repeated loading and unloading cycles without experiencing failure or damage due to fatigue.

- Q: Can aluminum sheets be used for decorative panels?

- Aluminum sheets are indeed suitable for decorative panels. Being a lightweight and versatile material, aluminum can be easily shaped, cut, and molded into various designs and patterns. Its sleek and modern appearance makes it a popular option for decorative purposes in both residential and commercial settings. Aluminum panels have a wide range of applications, including wall cladding, ceiling panels, room dividers, signage, and more. Moreover, aluminum is resistant to corrosion and weathering, making it suitable for both indoor and outdoor use. Additionally, aluminum panels can be personalized with different finishes, such as powder coating or anodizing, to enhance their visual appeal. In conclusion, aluminum sheets are an excellent choice for creating decorative panels due to their pleasing aesthetics, durability, and adaptability.

- Q: What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its thickness and dimensions.

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: What will reflect light more- aluminum foil or white paper?

- Indestructible okorder /

- Q: What is the typical corrosion resistance of aluminum sheets?

- The typical corrosion resistance of aluminum sheets is quite high. Aluminum naturally forms a protective oxide layer on its surface, which helps to prevent further corrosion. This oxide layer acts as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal. Additionally, aluminum is also highly resistant to many common types of corrosion, such as rusting and pitting. However, the corrosion resistance of aluminum can vary depending on various factors, such as the alloy composition, surface treatment, and exposure to harsh environments. Overall, aluminum sheets are known for their good corrosion resistance, making them suitable for a wide range of applications in various industries.

- Q: Is it possible to install aluminum sheets on an existing roof structure?

- <p>Yes, aluminum sheets can be installed on existing roofs. This process typically involves removing the old roofing material and ensuring the roof structure is sound. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them a popular choice for roof installations. They can be installed over a solid substrate, such as plywood or metal decking, and often require a proper underlayment to ensure watertightness. It's important to follow manufacturer guidelines and local building codes when installing aluminum sheets on an existing roof. Professional installation is recommended to ensure the roof's integrity and longevity.</p>

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Yes, aluminum sheets can be used for manufacturing aircraft parts. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry. It possesses excellent strength-to-weight ratio, corrosion resistance, and good formability, making it suitable for various aircraft applications. Aluminum sheets can be easily fabricated into complex shapes and are used to manufacture components such as wings, fuselages, panels, and structural supports in aircraft. Additionally, aluminum's high conductivity allows for efficient heat dissipation in critical areas of the aircraft. Overall, aluminum sheets are a preferred choice for manufacturing aircraft parts due to their favorable properties and reliability in the aerospace industry.

Send your message to us

aluminium stucco sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords