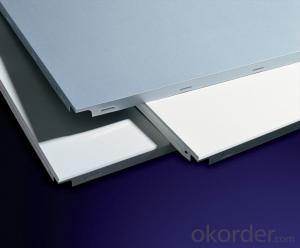

Plain aluminium sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

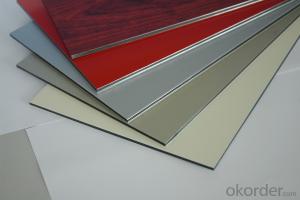

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

alulminium sheet

Features:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

6.Our quality is based on EN,ASTM,JIS.

7.We provide free sample service.

8.The products can be made according to your requirement.

9.Sincerely welcome your inquiry.

5000 series Aluminum coil :

a common choice for automobile manufacturing industry(car side door, mould, sealing parts) and tank making industry etc.

Specifications:colorful aluminium foil for medicine bottle caps

1.alloy 8011 h14

2.thickness 0.17-0.21mm

3.used aluminium vial seals

Packing: 80~100kgs per coil or as your requirement and use strong wooden box or pallet

Delivery Time: 25~35days after order and deposit

Payment: 30% T/T in advance, 70% balance payment against copy of B/L

Shipping:transportation by sea ,Ning Bo and Shang Hai port.

- Q: How do aluminum sheets perform in terms of heat reflectivity?

- Aluminum sheets exhibit remarkable heat reflectivity, making them exceedingly efficient. Their ability to effectively deflect heat and light away from surfaces minimizes heat absorption, thus rendering them perfect for scenarios where heat control is paramount, like roofing, insulation, and solar panels. The reflective quality of aluminum sheets aids in curbing energy consumption by preventing excessive heat accumulation, leading to a cooler atmosphere. Moreover, the reflectivity of aluminum also lends itself to a multitude of industrial and scientific applications, including the production of reflectors, heat sinks, and optical mirrors.

- Q: How to distinguish aluminum sheet from magnesium sheet?

- put two sheets into excess NaOH. The one that reacts with NaOH, generating sediment, is magnesium sheet,(sediment, but Al(OH)3 is amphoteric:Mg(OH)2) another one without sediment is aluminum sheet(in fact, there is sediment Al(OH)3, but it will react with alkali,)

- Q: Are the aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q: Is it possible to utilize aluminum sheets in the construction of high-rise buildings?

- <p>Yes, aluminum sheets can be used in high-rise buildings. They are valued for their lightweight, high strength, and resistance to corrosion. Aluminum is often used in curtain walls, window frames, and roofing due to its durability and recyclability. It also offers design flexibility and can be easily shaped and joined, making it suitable for modern architectural designs. However, it's important to ensure that the aluminum used meets the specific building codes and safety standards for high-rise construction.</p>

- Q: What will affect the performance of the aluminum ingot in the process of casting?

- We all know that in 50s our technical standards are from the former Soviet Union, "A00" is the national standard in the Soviet Russian brand, "A" is the Russian alphabet, rather than English "A" word, nor the Chinese phonetic alphabet "A" and the international community, "said standard aluminum is more precise. Standard aluminium is the aluminum ingot containing 99.7% aluminium, which is registered in the London market.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Do you want the lecture why you shouldn't be using aluminum utensils to cook with? Aluminum leeches out and is associated with dementia, birth defects, and heavy metal poisoning. In future, line your baking pans with parchment paper for 1) easy clean up and 2) to prevent metal leeching. Okay, now how to clean-to-gleam without scrubbing (which is pretty close to impossible). Method 1: Put your empty pans on the stove and heat them up until they are super hot (a baking sheet will need to cover two burners). Once they are really hot, stand back and pour water in them. This should at least loosen all the crud so you only need to to minimal swishing to remove most of it. Method 2: Put boiling water in your sink, a good dishwashing liquid such as Dawn de-greaser, and let your pans sit for an hour or so. Neither method will get your pans gleaming, only scrubbing will do that. But again, you don't want to scrub as you are then wearing away the surface of the metal which leads to more leeching. Many chemicals react negatively with aluminum, leaving dark stains on the metal. Mama never told you there'd be days like this because she thought you'd get yourself a set of stainless-steel Revereware cookware. Seriously, consider dumping all your aluminum (not just because of easy clean up, but for health) and replacing with stainless, glass, or steel or porcelain-coated. I know, standard baking sheets ALWAYS come in aluminum unless you're Gordon Ramsay and can afford over-the-top-quality stuff, so this is why god invented parchment paper.

- Q: Are aluminum sheets suitable for outdoor signage?

- Indeed, outdoor signage greatly benefits from the usage of aluminum sheets. Renowned for its durability and resistance to weather conditions, aluminum is capable of enduring the relentless forces of the outdoors, such as rain, wind, and sunlight. Furthermore, its corrosion-resistant properties make it the perfect choice for extended outdoor usage. Moreover, aluminum sheets possess the advantage of being lightweight, ensuring effortless handling and installation. Additionally, they can be conveniently cut, bent, or molded to fashion diverse signage designs. Given its sleek and professional aesthetic, aluminum is widely favored for outdoor signage in both commercial and industrial environments.

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- The most effective way is to directly use the cutting aluminum electrode wire. Solve the problems of burning, conducting blocks, breaking wires, cutting workpieces and so on. Since the conductive system of machine tool of high and modified carbon brush structure is not the same, will cause the machine not successful,

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Brake cleaner will stain. You need to go to a local auto parts store, like Pep Boys, or Autozone and get a container of Mother's aluminum wheel cleaner and polish. Then go into the aisle with the rags and get a bundle of terry towels and a bundle of baby diaper towels. You will need to use the cleaner/polish on the terry towels first and work in a circular motion, and don't be afraid to apply pressure. You will start to see the cleaner working when it starts turning black, DONT QUIT YET, continue working in a circular motion, and keep at it. After you are happy with the look of the aluminum use the baby diaper towels and wipe them clean in a circular motion also. You may have to repeat to get the desired effect, but in no time your wheels will look like new (or even better)! I have personally hand polished out many small parts, and even the radiator in my 63 impala (which was raw aluminum) with this stuff and it really works.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Yes, aluminum sheets can be used for manufacturing decorative trim.

Send your message to us

Plain aluminium sheet with competitive price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords