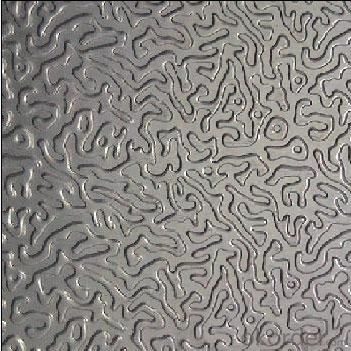

Perforated Stucco Aluminium Sheet-Aa3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1 Specifications of PE Coated Aluminum Coil/Sheet

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: What are the different forming methods for aluminum sheets?

- Aluminum sheets can be shaped using various forming methods. These methods encompass: 1. Roll Forming: By passing the aluminum sheets through a series of rollers, they gradually take on the desired form. Roll forming is commonly employed to produce elongated shapes like channels or rails. 2. Press Forming: This technique involves utilizing hydraulic or mechanical presses to exert force on the aluminum sheet, resulting in the desired shape. Press forming is often favored for creating intricate shapes with precise tolerances. 3. Stretch Forming: The aluminum sheet is clamped at its edges and then stretched over a die, causing it to conform to the die's shape. Stretch forming is frequently utilized to manufacture curved or contoured parts. 4. Deep Drawing: This method entails inserting an aluminum sheet blank into a die and using a punch to force the material into the die cavity, creating a hollow shape. Deep drawing is commonly employed for producing cylindrical or box-shaped parts. 5. Hydroforming: Hydraulic pressure is employed to shape the aluminum sheet against a die. Hydroforming is particularly advantageous for crafting complex shapes with smooth surfaces. 6. Incremental Sheet Forming: This technique involves a CNC machine moving a small tool over the aluminum sheet's surface, gradually shaping it by applying localized pressure. Incremental sheet forming is often employed for prototyping or small-scale production. These forming methods offer distinct advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and production volume.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Yes, aluminum sheets are suitable for furniture manufacturing. Aluminum is a lightweight and versatile material that offers numerous advantages for furniture production. It is corrosion-resistant, making it ideal for both indoor and outdoor furniture. Additionally, aluminum has a high strength-to-weight ratio, allowing for the creation of sturdy and durable furniture pieces. It is also easy to work with, as it can be cut, bent, and welded into various shapes and designs. Moreover, aluminum can be finished with different coatings or paints to enhance its appearance and protect it from wear and tear. Overall, aluminum sheets are a viable option for furniture manufacturing due to their strength, versatility, and aesthetic appeal.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a popular material for balcony railings due to its lightweight nature, durability, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and designs, making it suitable for various architectural styles. Additionally, aluminum railings require minimal maintenance and can withstand harsh weather conditions, making them a practical and long-lasting choice for balcony railings.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels.

- Q: What are the different types of alloys used for aluminum sheets?

- Aluminum sheets can be made from different types of alloys, each with its own unique properties and uses. Here are some of the most commonly used ones: - The 1100 alloy is pure aluminum and has excellent resistance to corrosion and good formability. It is often utilized for general sheet metal work like roofing and siding. - The 3003 alloy is similar to 1100 but contains added manganese, which makes it slightly stronger. It is commonly employed for applications that require moderate strength and good resistance to corrosion, such as packaging and automotive parts. - The 5052 alloy is renowned for its exceptional corrosion resistance, particularly in marine environments. It is also highly formable and weldable, making it suitable for various applications like fuel tanks, marine components, and architectural panels. - The 6061 alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and resistance to corrosion. It is commonly found in structural applications like aircraft parts, bicycle frames, and automotive components. - The 7075 alloy is a high-strength alloy frequently utilized in aerospace and military applications. It exhibits excellent resistance to fatigue and is easily machinable. It is typically employed for aircraft structures, missile parts, and high-stress components. These examples illustrate the variety of aluminum alloys available for sheet production. The choice of a specific alloy depends on desired properties, such as strength, resistance to corrosion, formability, and cost, as well as the intended application.

- Q: What are the different methods for punching aluminum sheets?

- There are several methods for punching aluminum sheets, including manual punching with hand tools, mechanical punching using punch presses, and CNC punching using computer-controlled machines. Each method has its own advantages and is chosen based on factors such as the required precision, volume of production, and complexity of the punched shapes.

- Q: In which autocomponents usage of aluminium is better or otherwise?

- Aluminium is lighter as well as stronger than CI. Thats the reason most of the Automobile manufacturers use Aluminium for car bodies while they use cast iron for the underframes and internal chassis....NMN

- Q: Can aluminum sheets be used for signage?

- Signage can indeed utilize aluminum sheets. Aluminum, a versatile and durable material, is frequently employed in the sign-making industry. Its lightweight yet sturdy properties make it well-suited for both outdoor and indoor signage. Additionally, aluminum sheets are resistant to corrosion, rust, and fading, guaranteeing signage longevity. They can also be easily cut and shaped into various sizes and designs, providing creative and customized signage solutions. Furthermore, the material offers a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly adaptable for different signage applications. In conclusion, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a favored choice for signage.

- Q: Are aluminum sheets suitable for use in harsh chemical environments?

- Aluminum sheets are indeed suitable for usage in harsh chemical environments. Their remarkable resistance to numerous chemicals, including acids, alkalis, and organic solvents, is noteworthy. The formation of a protective oxide layer on the surface of aluminum aids in preventing corrosion. Moreover, aluminum's lightweight nature, durability, and cost-effectiveness have contributed to its widespread use in various industrial applications within harsh chemical environments. Nevertheless, it is essential to acknowledge that the appropriateness of aluminum sheets in particular chemical environments may also be influenced by factors such as temperature, concentration, and duration of exposure to the chemicals. To ensure the proper selection of materials for a given chemical environment, it is always advisable to consult experts or refer to specific chemical compatibility charts.

Send your message to us

Perforated Stucco Aluminium Sheet-Aa3xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords