First Street Aluminum Foil Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

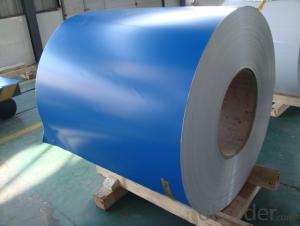

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, H22, H44,H112,F,O, H114,etc.

2. Main features of the product

a. price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

2000mm*2000mm,1000*1000MM, 1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be used for electrical connectors?

- Yes, aluminum sheets can be used for electrical connectors. Aluminum is a highly conductive material and has excellent electrical conductivity. It is commonly used in various electrical applications, including connectors. Aluminum connectors are lightweight, durable, and cost-effective compared to other materials such as copper. However, it is important to consider certain factors such as the type and size of the connection, the amount of current to be carried, and the environment in which the connectors will be used. Additionally, proper insulation and protection measures should be taken to prevent corrosion, as aluminum can be susceptible to oxidation. Overall, aluminum sheets can be a suitable choice for electrical connectors, but careful consideration of specific requirements and conditions is necessary.

- Q: ive been working with parts for a robot without gloves and ive manged to 3 cuts in my fingers, also my hands get covered with powdered aluminum from sanding the peices, can this be dangerous to my health?

- When working with aluminum, wear leather gloves to protect your hands, goggles to protect your eye and a dust mask to protect your lungs. Aluminum has been linked to Alzheimer's and other neurological conditions.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- Neither is great, but aluminum is worse (especally when heated). Also you can't put aluminum in the microwave since it sparks (technically it should not be used for cooking), but plastic leaches stuff info food, especially if it's via ceranwrap on top (in a microwave). Storing things in platic tupperware in the fridge is fine since the temperatures are cold enough that no reactions can happen, but for cooking and eating, ceramic is preferable. Aluminum on the other hand should just be avoided (for baking pyrex glass/ceramic is better). Out of all the forms of aluminum, aluminum foil is the most likely to leech stuff. Hope that helps!

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: i heard that aluminum causes Alzheimers and i was wondering if there is any aluminum in tin.

- no, tin is tin it's one of the periodic elements.

- Q: Can 101 aluminum sheets be stamped or engraved?

- Yes, 101 aluminum sheets can be stamped or engraved.

- Q: Are aluminum sheets suitable for electrical conductors?

- Yes, aluminum sheets are suitable for electrical conductors due to their high electrical conductivity, lightweight nature, and cost-effectiveness.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Yes, aluminum sheets can be used for manufacturing audio amplifier cases. Aluminum is a commonly used material in the manufacturing of electronic equipment due to its lightweight, durability, and excellent heat dissipation properties.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: This question asks for a comparison of the cost of aluminum sheets with other building materials.

- <p>Aluminum sheets are generally considered cost-effective compared to other building materials, especially when considering their long-term benefits. They are relatively inexpensive to produce and install, and their low maintenance requirements can save costs over time. However, their initial cost may be higher than some materials like wood or vinyl. Aluminum's resistance to corrosion and weathering means it lasts longer, which can offset the higher upfront cost. In contrast, materials like steel might be more expensive due to their weight and the cost of corrosion protection, while concrete and masonry are typically more costly for both materials and labor. The cost-effectiveness of aluminum can vary based on regional prices, specific project requirements, and the type of aluminum product (e.g., thickness, finish).</p>

Send your message to us

First Street Aluminum Foil Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords