Aluminum Roofing Sheets in Nigeria - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

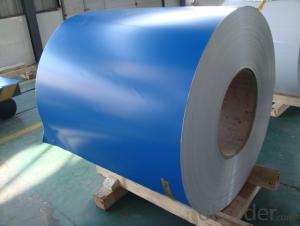

we are from cnbm international corporatoin, including different grades, such as: cold rolled sheet, hot rolled sheet, checkered sheet, mirror finish aluminum sheet, etc. the thicness is very changing from different sizes.Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, H22, H24, H44,O, F, ETC. H112,H114,etc.

2. Main features of the product

a. best best competitive price

b.Frist-Class Service.

c. Shortest service.

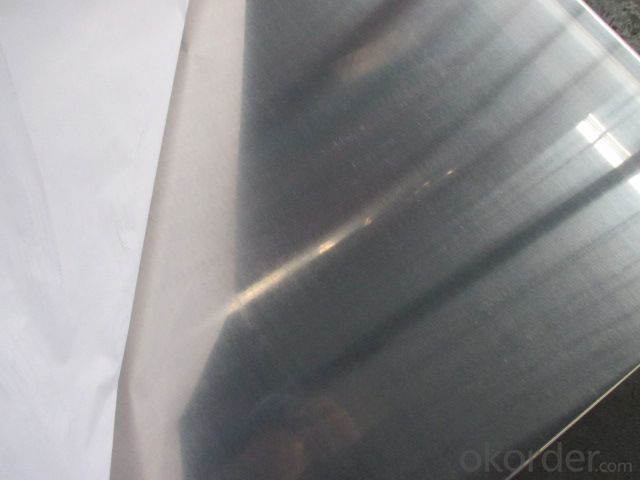

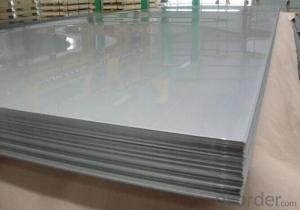

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1500*3000MM, 1220mm*2440mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 200mm to 2500mm, etc.

---Normally it is from SRI LANKA, BANGLADESH, ETC.

Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Yes, aluminum sheets are highly suitable for manufacturing lightweight structures. Aluminum is known for its low density, making it one of the lightest metals available. This characteristic makes aluminum sheets an excellent choice for various applications where weight reduction is a priority, such as aerospace, automotive, and construction industries. Additionally, aluminum has a high strength-to-weight ratio, meaning it can withstand significant loads while still remaining lightweight. Furthermore, aluminum sheets offer excellent corrosion resistance, making them suitable for outdoor and marine applications. Overall, the combination of its lightness, strength, and durability makes aluminum sheets a preferred choice for manufacturing lightweight structures.

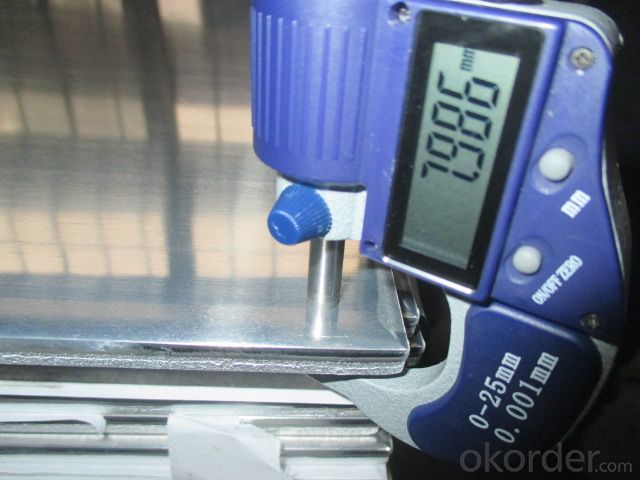

- Q: What are the typical thickness options for aluminum sheets?

- The typical thickness options for aluminum sheets range from 0.006 inches to 0.25 inches, depending on the specific application and requirements.

- Q: What is the typical hardness of aluminum sheets?

- The hardness of aluminum sheets can differ based on the particular alloy and temper, resulting in a range of 40 to 70 on the Brinell hardness scale (HB). This level of hardness facilitates the ease of forming, machining, and fabricating aluminum sheets, rendering them applicable in various industries such as aerospace, automotive, construction, and manufacturing. Notably, the hardness of aluminum sheets can be enhanced further by undergoing heat treatment processes like annealing or hardening, allowing them to meet specific demands and enhance their mechanical properties.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: What are the different types of alloys used for aluminum sheets?

- Aluminum sheets can be made from different types of alloys, each with its own unique properties and uses. Here are some of the most commonly used ones: - The 1100 alloy is pure aluminum and has excellent resistance to corrosion and good formability. It is often utilized for general sheet metal work like roofing and siding. - The 3003 alloy is similar to 1100 but contains added manganese, which makes it slightly stronger. It is commonly employed for applications that require moderate strength and good resistance to corrosion, such as packaging and automotive parts. - The 5052 alloy is renowned for its exceptional corrosion resistance, particularly in marine environments. It is also highly formable and weldable, making it suitable for various applications like fuel tanks, marine components, and architectural panels. - The 6061 alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and resistance to corrosion. It is commonly found in structural applications like aircraft parts, bicycle frames, and automotive components. - The 7075 alloy is a high-strength alloy frequently utilized in aerospace and military applications. It exhibits excellent resistance to fatigue and is easily machinable. It is typically employed for aircraft structures, missile parts, and high-stress components. These examples illustrate the variety of aluminum alloys available for sheet production. The choice of a specific alloy depends on desired properties, such as strength, resistance to corrosion, formability, and cost, as well as the intended application.

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies based on the specific alloy and temper of the material. In general, aluminum alloys have a lower shear strength compared to steels, but higher than most other non-ferrous metals. The shear strength can range from around 30 to 60 MPa (MegaPascals) for commonly used aluminum alloys in sheet form. However, it should be noted that these values can change depending on factors like thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to refer to the specific material datasheet or reach out to the manufacturer for accurate and detailed information regarding the shear strength of a particular aluminum sheet.

- Q: which kind of aluminum sheet could be bended after being etched?

- general etching materials include stainless steel and copper.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: This question asks for a list of various types of aluminum sheets that can be used for decorative purposes.

- <p>Aluminum sheets are popular for decorative purposes due to their durability and versatility. The main types include: 1) Embossed Aluminum Sheets, which feature a textured surface for a unique look; 2) Perforated Aluminum Sheets, with holes of various sizes for a distinctive pattern; 3) Mirror Finish Aluminum Sheets, offering a reflective, shiny appearance; 4) Anodized Aluminum Sheets, which have a protective oxide layer for enhanced color and durability; 5) Brushed Aluminum Sheets, with a satin-like finish; 6) Color Coated Aluminum Sheets, available in a wide range of colors; 7) Composite Aluminum Panels, which combine aluminum with other materials for added strength and design options. Each type offers specific aesthetic and functional benefits for various decorative applications.</p>

- Q: Can aluminum sheet be used for automotive applications?

- Indeed, aluminum sheet finds its application in the automotive industry. Offering a combination of lightness and strength, aluminum serves as a highly advantageous material. Car bodies, hoods, doors, and various structural components are extensively manufactured using aluminum. The preference for aluminum sheets in these applications stems from their exceptional strength-to-weight ratio, resistance against corrosion, and durability. Moreover, aluminum exhibits ease in forming, enabling the attainment of intricate shapes and designs. The utilization of aluminum in automotive applications further contributes to enhanced fuel efficiency and reduced emissions due to its reduced weight. Ultimately, the manifold advantageous characteristics of aluminum sheets render them a suitable choice for automotive applications.

Send your message to us

Aluminum Roofing Sheets in Nigeria - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords