Aluminum Roofing Sheets for Stick Curtain Walls in Nigeria

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

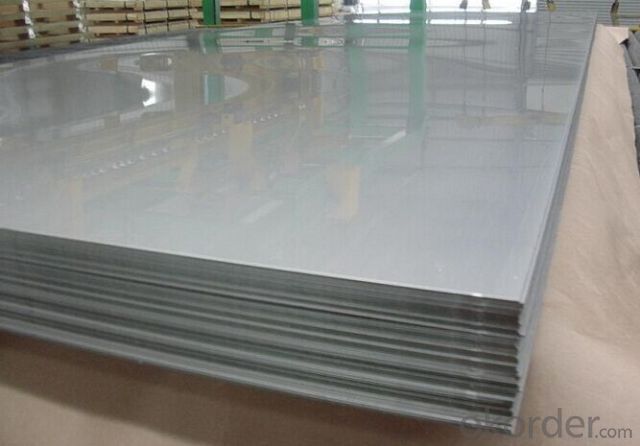

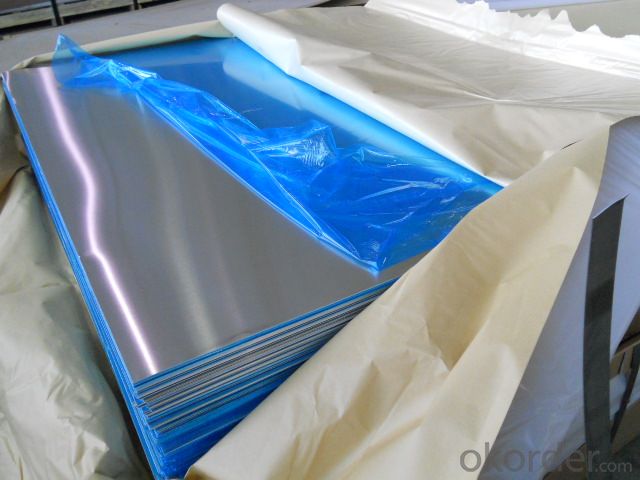

1.Structure of Aluminium Sheets for Stick Curtain Walls

Aluminum Sheets for stick curtain walls are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

Aluminum Sheets for stick curtain walls are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

2.Main Features of Aluminium Sheets for Stick Curtain Walls

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

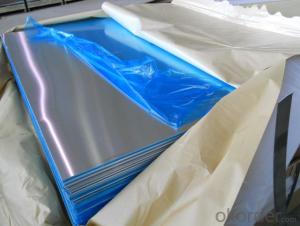

3. Aluminium Sheets for Stick Curtain Walls Images

4.Specification of Aluminium Sheets for Stick Curtain Walls

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: what's the difference between the knocking voice of aluminum sheet and stainless steel?

- The voice of aluminum sheet is toneless, and the voice of stanless steel is more crisp.

- Q: What is the electrical resistivity of aluminum sheets?

- Aluminum sheets usually exhibit an electrical resistivity within the range of 2.65 to 2.82 micro-ohm centimeters. Nevertheless, it should be emphasized that the precise resistivity is subject to variation based on factors such as the alloy composition, thickness, temperature, and other considerations.

- Q: Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are versatile in construction due to their strength, durability, and lightweight properties. They are used for roofing and cladding to provide weather resistance and aesthetic appeal. Aluminum sheets are also utilized in the fabrication of window frames and doors for their strength and thermal efficiency. They are employed in the construction of scaffolding and temporary structures due to their lightweight and ease of assembly. Additionally, aluminum sheets are used in the manufacturing of facades, canopies, and decorative elements for their modern look and low maintenance requirements.</p>

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q: What are the standard tolerances for aluminum sheets?

- The standard tolerances for aluminum sheets vary depending on the specific industry and application. However, some commonly accepted tolerances for aluminum sheets include thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances refer to the allowable variation in the thickness of an aluminum sheet. These tolerances can range from +/- 0.005 inches to +/- 0.010 inches, depending on the grade and thickness of the sheet. Flatness tolerances specify the degree of flatness or deviation from a perfectly flat surface that is acceptable for an aluminum sheet. Flatness tolerances can range from a few thousandths of an inch to a few hundredths of an inch, depending on the specific requirements of the application. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be specified in terms of +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets are in the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and can vary depending on the specific industry, customer requirements, and the capabilities of the manufacturer. Therefore, it is always recommended to consult the manufacturer or industry-specific standards to determine the precise tolerances for aluminum sheets in a particular application.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- 101 aluminum sheets are not appropriate for applications involving conductive heat transfer. This specific aluminum alloy, known as 101 aluminum, is commercially pure and has a low electrical conductivity. Consequently, it is ineffective at efficiently conducting heat, rendering it unsuitable for situations requiring heat transfer. Instead, it is advisable to employ alloys with higher thermal conductivity, such as 6061 or 7075 aluminum, for conductive heat transfer applications. These alloys possess superior heat transfer properties and are commonly utilized in heat sinks, heat exchangers, and other scenarios demanding efficient heat transfer.

- Q: How thick are aluminum sheets commonly available?

- Depending on the purpose and application, aluminum sheets are typically available in different thicknesses. The most frequently found aluminum sheet thicknesses range from 0.025 inches (0.63 mm) to 0.125 inches (3.18 mm). Nevertheless, there are also thinner and thicker aluminum sheets obtainable, with some being as thin as 0.016 inches (0.4 mm) and others as thick as 0.25 inches (6.35 mm) or possibly more. The specific thickness needed will be contingent upon the particular project or industry application.

- Q: This question asks for methods to determine the thickness of aluminum sheets.

- <p>To measure the thickness of aluminum sheets, you can use various methods including mechanical thickness gauges, ultrasonic thickness gauges, or calipers. Mechanical gauges are simple and involve sliding a foot along the sheet until it bottoms out on both sides. Ultrasonic thickness gauges use sound waves to measure thickness and are non-destructive, providing accurate measurements. Calipers can also be used for manual measurement, though they may be less precise for very thin sheets. Always ensure the measuring device is calibrated and suitable for the material and thickness range of the aluminum sheet in question.</p>

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Aluminum Roofing Sheets for Stick Curtain Walls in Nigeria

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords