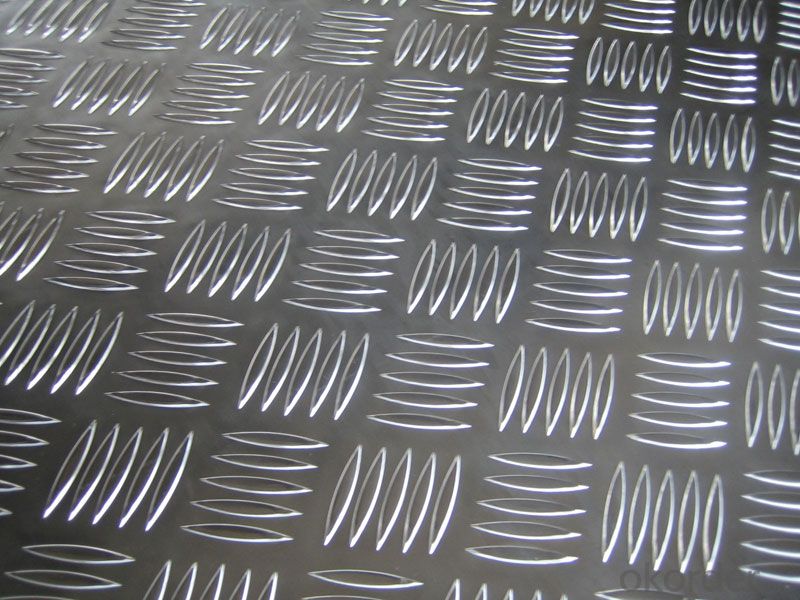

Painted Aluminum Sheets - Aluminium Tread Plate Small Five Bar Pattern Plate in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are one of the largest aluminum producer in China, and we also use of aluminum rod, billets, rod, foils, sheet, circles, embossed coil etc.We have produced Aluminum Coils over 10 years, and we have good reputation of the price and quality in China

| Aluminum Coil/Sheet | ||||||||

| Main Specification | ||||||||

| Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) | |||||||

| AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | ||||||||

| AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | ||||||||

| AA8xxx(AA8011, AA8006 etc.) | ||||||||

| Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 | |||||||

| Thickmess | 0.01mm-100mm | |||||||

| Width | 30mm-1700mm | |||||||

| Standard | GB/T 3880-2006/ASTM | |||||||

| Special specification is available on customer's requirement | ||||||||

Description:

Small Five Bars Sheet/Big Five Bars Sheet

Alloy: 1100/1050/1060/3003/3105/5052

Thickness: 0.7-8mm

Width: 100-1500mm

Length: Max 6000mm

standard:GB/T3618-2006

End use: Construction, Decoration, Anti-skid and protection in automobile, Trucks , Steamer construction, etc.

- Q: Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- rethink your question, is non sensical at this point.

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- No, 101 aluminum sheets are not suitable for cryogenic applications. While aluminum is generally a good choice for low-temperature environments due to its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to withstand the extreme temperatures associated with cryogenic applications. For cryogenic applications, materials such as aluminum alloys (e.g., 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are typically used, as they possess enhanced properties to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is recommended to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: What is the modulus of elasticity for aluminum sheets?

- Aluminum sheets possess a modulus of elasticity, commonly referred to as Young's modulus, which typically ranges at approximately 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This numerical figure signifies the extent of stiffness and rigidity exhibited by the material. Nevertheless, it is crucial to acknowledge that the modulus of elasticity may experience slight variations contingent upon the precise alloy composition and tempering of the aluminum sheet.

- Q: Aluminum is put into copper chloride and how can you tell what happens to them visually?

- appropriate you're watching basically worry-unfastened atoms of rely. Protons are somewhat charged debris, the quantity of protons an atom has determines the form of atom itself. for example one proton is hydrogen, six protons is for carbon, etc. The neutrons are have not have been given any can charge in an atom, and help stabilize the atom. undergo in techniques like expenses repel eachother, neutrons carry the protons at the same time. They the two have basically approximately the comparable mass. finally electrons have a adverse can charge and bypass around atoms in unpredictable techniques. The closer the kind of electrons there are in an atom to protons, the greater impartial that's. An atom is impartial at the same time as there are 8 valence electrons indoors the outer shell distinctive than fir helium with basically 2. undergo in techniques, that's basically your undertaking-loose grade 9 stuff, now no longer the actual fact i understand.

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes through a process called extrusion.

- Q: Can aluminum sheets be used for battery casings?

- Yes, aluminum sheets can be used for battery casings. Aluminum is a lightweight and durable metal that offers excellent corrosion resistance, making it a suitable choice for battery casings. It is also a good conductor of electricity, which is important for efficient battery performance. Additionally, aluminum is easily formable and can be shaped into various designs and sizes, allowing for flexibility in battery casing manufacturing. Overall, aluminum sheets are commonly used in the production of battery casings due to their beneficial properties.

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Yes, aluminum sheets are suitable for manufacturing architectural ceiling panels due to their lightweight properties, durability, and corrosion resistance. Additionally, aluminum sheets can be easily formed, cut, and fabricated into various shapes and designs, making them a popular choice for ceiling panels in architectural applications.

- Q: What are aluminum sheets?

- Aluminum sheets, commonly found in various industries and applications, are thin and flat pieces of aluminum. Aluminum, a lightweight and versatile metal, is known for its exceptional strength, durability, and corrosion resistance, from which these sheets are made. Depending on the project's specific requirements, the thickness, width, and length of these sheets can vary. Construction, automotive, aerospace, packaging, and manufacturing industries, among others, widely employ aluminum sheets. They serve various purposes, including roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. Aluminum's flexibility and malleability make it a popular choice for a wide range of applications, as it can be easily shaped and formed. Furthermore, aluminum sheets can be coated or finished, enhancing their appearance and protecting them from external factors like moisture, UV rays, or chemicals. In summary, aluminum sheets are indispensable materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for industrial and commercial uses.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- This Site Might Help You. RE: Spray Paint Aluminium Durable. Matte. Finish? Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually...

Send your message to us

Painted Aluminum Sheets - Aluminium Tread Plate Small Five Bar Pattern Plate in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords