Aluminum Sheets for Travel Trailers - Best Quality Aluminum Alloy Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Alloy Sheet

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Alloy Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Alloy Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

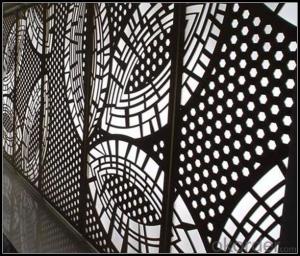

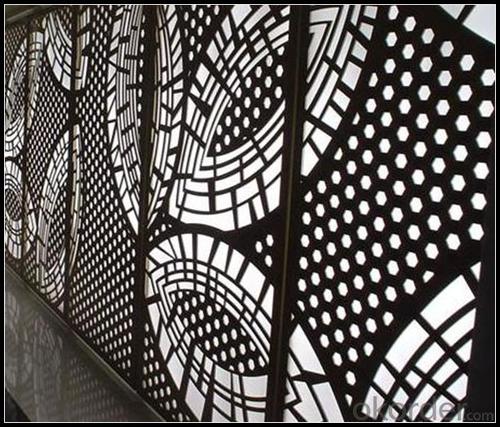

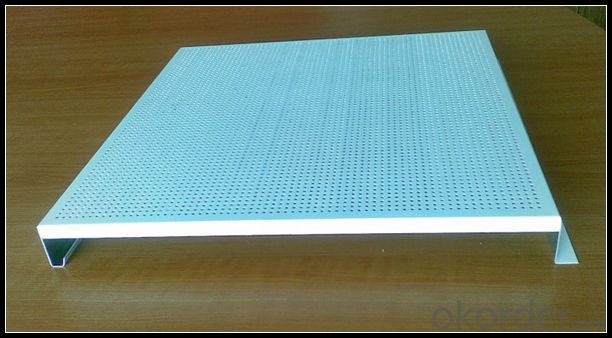

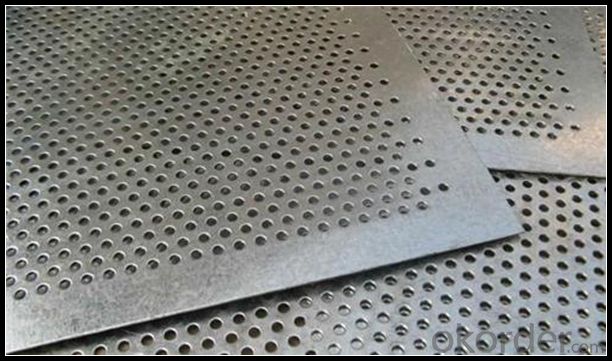

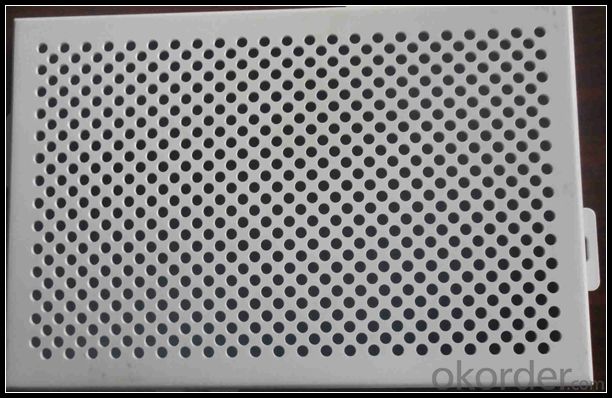

5. Image of Aluminum Alloy Sheet

6. Package and shipping of Aluminum Alloy Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are 101 aluminum sheets suitable for decorative purposes?

- 101 aluminum sheets are excellent for decorative purposes. They are crafted from top-notch aluminum alloy, resulting in a smooth and refined look. Their exceptional resistance to corrosion and ease of cleaning make them perfect for embellishing purposes. Furthermore, these sheets can be effortlessly shaped and cut, enabling the creation of unique designs and personalized touches. Whether it be for interior or exterior decoration, these sheets are versatile and can be utilized for wall cladding, signage, furniture accents, and other applications. With their durability and visually pleasing attributes, 101 aluminum sheets offer a splendid option for adding a touch of sophistication to any environment.

- Q: Which kind of glue is best for bonding aluminum sheets?

- I advice you to use AB glue to bond aluminum sheets, acylic acid AB glue is better than 502 in bonding aluminum sheets, Gelianghao XSSS-290AB glue sold in hardware store can directly permeate into the surface of aluminum sheets and bond the sheets tightly.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. Aluminum sheets should be stored in a clean and dry area to prevent any moisture absorption or corrosion. They should be kept in a well-ventilated space to avoid the buildup of any potentially harmful gases. It is important to stack the sheets properly, with adequate support and spacing, to prevent any bending or deformation. Additionally, aluminum sheets should be protected from direct sunlight to avoid any discoloration or fading. It is recommended to cover them with a suitable material, such as a plastic sheet or tarp, to provide an extra layer of protection. Proper storage conditions will help maintain the quality and integrity of the aluminum sheets for their intended use.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. Aluminum is a versatile and lightweight material that possesses several beneficial properties for construction purposes. It is corrosion-resistant, making it suitable for both indoor and outdoor applications. Aluminum sheets also have high strength-to-weight ratio, meaning they offer strength and durability while remaining relatively lightweight, which can be advantageous in construction projects where weight is a concern. Additionally, aluminum is non-toxic and highly recyclable, making it an environmentally friendly choice. These factors, combined with its aesthetic appeal and ease of fabrication, make aluminum sheets a popular choice for various construction applications such as roofing, cladding, wall panels, window frames, and more.

- Q: How does the thickness of aluminum sheet affect its strength?

- The strength of an aluminum sheet is directly influenced by its thickness. Generally, a thicker aluminum sheet will possess greater strength compared to a thinner one. This correlation arises from the fact that the thickness of the sheet determines the quantity of material present, ultimately impacting its ability to endure external forces or loads. Typically, the strength of a material is measured based on its capacity to withstand stress without deforming or failing. Thicker aluminum sheets have a larger volume of material, resulting in an increased number of atoms and bonds to counteract forces. Consequently, these sheets exhibit a heightened resistance to deformation or failure, thus rendering them stronger. Furthermore, thicker aluminum sheets boast a higher load-bearing capacity. Consequently, they can endure heavier loads or higher pressures without distorting or failing. The augmented thickness allows for a greater distribution of the load, thereby reducing the stress placed on individual atoms and bonds within the sheet. Nevertheless, it is crucial to acknowledge that there exists a limit to the thickness at which the strength of an aluminum sheet reaches a plateau. Once this threshold is surpassed, further increasing the thickness may not yield significant improvements in strength. This limitation arises from the influence of other material properties of aluminum, such as its crystal structure and grain boundaries, which also contribute to determining its strength. To conclude, the strength of an aluminum sheet is directly linked to its thickness. Thicker sheets possess more material, enabling them to effectively resist deformation or failure under stress. Furthermore, their increased thickness allows them to support heavier loads or endure higher pressures. However, it is important to recognize that there is a limit to the thickness at which the strength plateaus, as other material properties also come into play.

- Q: Can aluminum sheets be used in aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry. Aluminum has several properties that make it an ideal material for aerospace applications. Firstly, it is lightweight, which is crucial for aircraft and spacecraft as it helps reduce fuel consumption and increase payload capacity. Secondly, aluminum has excellent strength-to-weight ratio, providing the necessary structural integrity for aerospace components. Additionally, aluminum is highly corrosion-resistant, ensuring durability and longevity in harsh environments. It also has good thermal conductivity, making it suitable for heat dissipation in aerospace systems. Furthermore, aluminum is easily formable, allowing for complex shapes and structures to be manufactured. Overall, the versatility, strength, lightness, and corrosion resistance of aluminum make it a preferred material in the aerospace industry for various applications such as aircraft frames, fuselage panels, wings, and engine components.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- This Site Might Help You. RE: Is there a angle grinder cut off wheel made for cutting aluminum? Hello, Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum? Thanks!

Send your message to us

Aluminum Sheets for Travel Trailers - Best Quality Aluminum Alloy Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords