Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

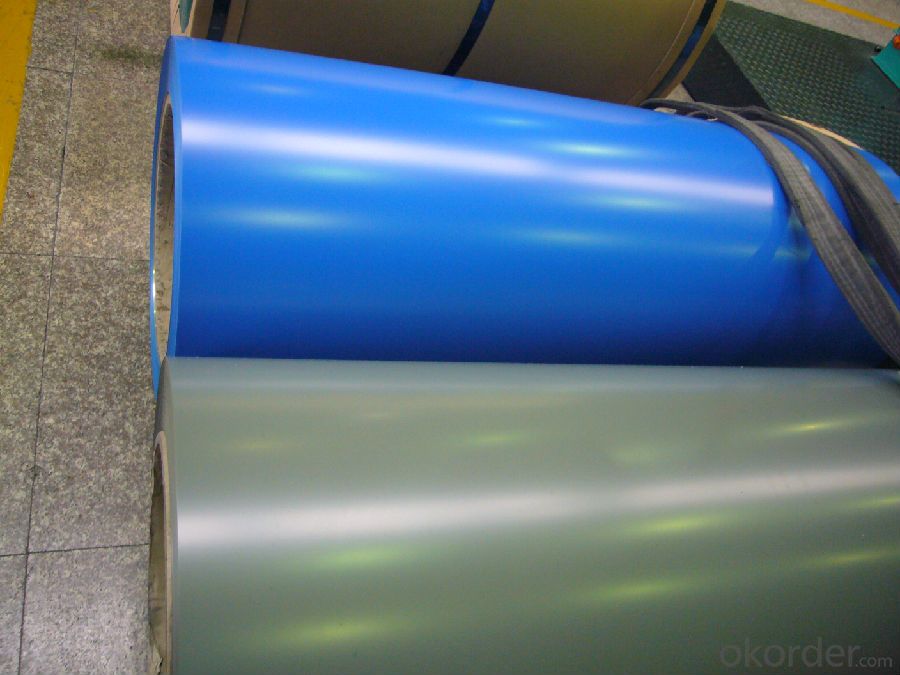

1.Structure of Aluminium Back Coils for Aluminium Composite Panel

Aluminium Back Coils for Aluminium Composite Panel are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Aluminium Back Coils for Aluminium Composite Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Coating | Coating Thickness | Weight |

| AA1050 | H14 | Polyester | 20-25microns | about 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets are suitable for electrical bus bars. Aluminum is a lightweight and cost-effective material that exhibits good electrical conductivity. It is commonly used in various electrical applications, including bus bars, due to its ability to efficiently carry high electrical currents while dissipating heat effectively.

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. Aluminum sheets should be stored in a clean and dry area to prevent any moisture absorption or corrosion. They should be kept in a well-ventilated space to avoid the buildup of any potentially harmful gases. It is important to stack the sheets properly, with adequate support and spacing, to prevent any bending or deformation. Additionally, aluminum sheets should be protected from direct sunlight to avoid any discoloration or fading. It is recommended to cover them with a suitable material, such as a plastic sheet or tarp, to provide an extra layer of protection. Proper storage conditions will help maintain the quality and integrity of the aluminum sheets for their intended use.

- Q: This question asks for methods to ensure a project remains cost-effective when using aluminum sheets.

- <p>To ensure your project is cost-effective using aluminum sheets, first, source high-quality aluminum at competitive prices. Consider buying in bulk to reduce per-unit costs. Second, optimize your design to minimize material usage without compromising strength. Use precise cutting techniques to reduce waste. Third, collaborate with reliable suppliers who can offer cost-effective solutions and may provide discounts for long-term partnerships. Lastly, monitor and control your project's budget closely, and consider the lifecycle costs, including maintenance and potential resale value, to ensure long-term cost-effectiveness.</p>

- Q: How do you prevent oil or grease stains on aluminum sheets?

- One effective way to prevent oil or grease stains on aluminum sheets is to apply a protective coating or finish. This can be done by using a specialized oil-resistant sealant, such as a clear lacquer or anodizing the aluminum. Additionally, maintaining a clean and dry surface, regularly wiping away any spills or residue, and using non-greasy or oil-free tools and equipment can help minimize the chances of stains occurring.

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Yes, 101 aluminum sheets are suitable for automotive body panels. 101 aluminum is a high-strength alloy that offers good formability and corrosion resistance, making it an excellent choice for automotive applications. It is lightweight, which helps improve fuel efficiency and overall vehicle performance. Additionally, 101 aluminum has good dent resistance, ensuring that the body panels can withstand impacts and maintain their structural integrity. Overall, using 101 aluminum sheets for automotive body panels is a practical and effective choice.

- Q: Can aluminum sheet be used for electrical conductivity applications?

- Yes, aluminum sheet can be used for electrical conductivity applications. Aluminum has good electrical conductivity properties, making it suitable for various electrical applications such as wiring, connectors, and conductive components.

- Q: What are the potential health hazards related to working with aluminum sheets?

- <p>Working with aluminum sheets generally has low health risks. However, inhalation of aluminum dust can cause respiratory issues, such as coughing and shortness of breath. Prolonged exposure may lead to a condition known as metal fume fever. Additionally, aluminum can cause skin irritation in some individuals. It's important to use proper ventilation and personal protective equipment, such as masks and gloves, to minimize these risks.</p>

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- I'm going to show my calculations anyways Fe2O3(s) + 2 Al(s) -- 2 Fe (l) + Al2O3 (s) From the equation : 1 mole of iron (III) oxide 2 moles of aluminium -- 2 moles of iron 1 mole of aluminium oxide Given that iron = 10.0 g = 10.0 g / 55.8 g per mole = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to iron (III) oxide is 2 : 1 Therefore moles of iron (III) oxide produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (55.8 x 2 + 16.0 x 3) = 14.3 grams (corr to 3 sig fig)' a) 14.3 grams of iron (III) oxide must be used ----- Given that iron = ...... (previously calculated) ...... = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to aluminium is 1 : 1 Therefore moles of aluminium produced = 0.179 mol Convert it back to grams 0.179 x 27.0 = 4.83 grams (corr to 3 sig fig) b) 4.83 grams of aluminium must be used ----- Given that iron = 0.179 mol Because the mole ratio of iron to aluminium oxide is 2 : 1 Therefore moles of Al2O3 produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (27.0 x 2 + 16.0 x 3) = 9.13 grams (corr to 3 sig fig) c) 9.13 grams of aluminium oxide is the maximum mass that could be produced P.S. The relative molecular masses used are from my textbook

- Q: Explain the distinctions between aluminum and steel sheets in terms of their properties and applications.

- <p>Aluminum sheets and steel sheets differ in material composition, weight, strength, and applications. Aluminum sheets are lightweight, corrosion-resistant, and have good thermal conductivity, making them ideal for applications requiring light weight and resistance to corrosion. Steel sheets, on the other hand, are heavier, stronger, and more durable, suitable for structural applications where high strength is required. Steel is also magnetic, which aluminum is not, and has a higher melting point. However, steel is more prone to rust compared to aluminum, which requires protective coatings or treatments in many applications.</p>

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Aluminum Alloy Sheets for Spaceflight - Aluminium Back Coils for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords