Aircraft Aluminum Sheets 025 5x10 for Metal Roofing System Aluminium Panels Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Panels Price for Metal Roofing System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminium Panels Price for Metal Roofing System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

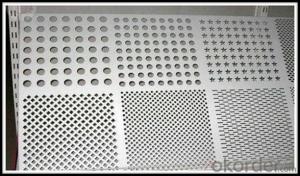

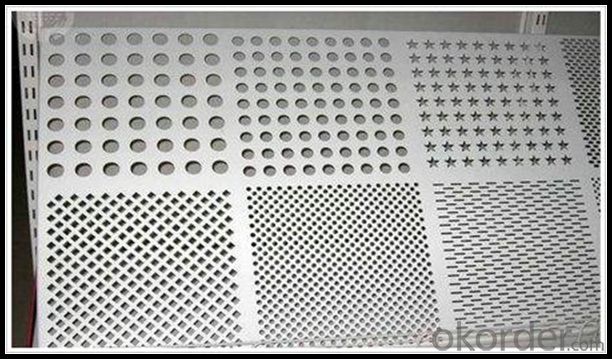

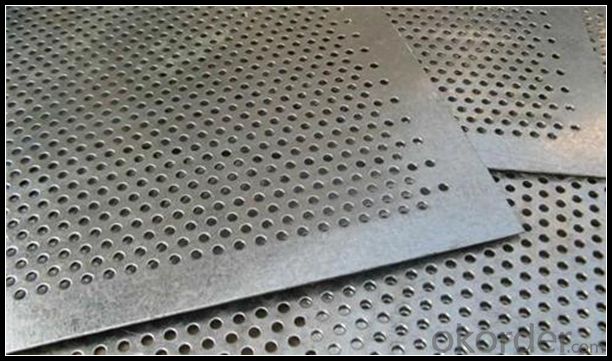

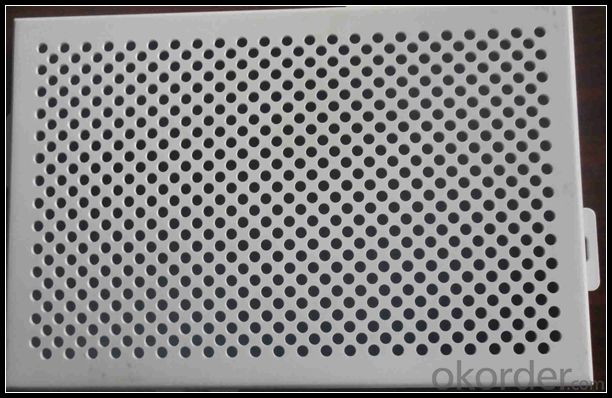

3. Image of Aluminium Panels Price for Metal Roofing System

4.Specification of Aluminium Panels Price for Metal Roofing System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- Aluminum sheet material, 1100, 1060, 3003, 5052, 5083, 6061, 8011, 7075 and so on.The thickness of aluminum plate is 0.15mm-500mm, width is 100mm-2000mm, length is: 1000mm-9000mm,Aluminum roll thickness is 0.05mm-15mm, width is: 15mm-2000mmThickness of insulated aluminium plate: 0.3mm-0.9mm width: 500mm-1000mm length: no limitNon slip pattern aluminum plate thickness: 1mm-10mm width: 1000mm-1500mm length: 2000-3000mmEmbossed aluminum plate thickness: 0.1mm-0.9mm width: 500mm-1200mm length: UnlimitedAluminum tube specification: outside diameter range: Phi 3mm to Phi 500mm, wall thickness range: 3mm ~ 50mm, aluminum square tube specification: 10mm*10mm to 200mm*200mm, wall thickness range: 3mm ~ 20mm

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can be a viable alternative to plastic in certain applications. Aluminum is a lightweight and durable material that offers numerous advantages over plastic. It has excellent strength-to-weight ratio, making it suitable for applications that require resistance to impact or heavy loads. Additionally, aluminum is highly resistant to corrosion, which makes it ideal for outdoor or marine applications where plastic may degrade over time. Moreover, aluminum is a highly recyclable material, which aligns with the growing emphasis on sustainability and reducing waste. Unlike plastic, which can take hundreds of years to decompose, aluminum can be recycled indefinitely without losing its properties. This makes aluminum a more environmentally friendly choice for applications where plastic waste is a concern. Furthermore, aluminum sheets offer superior thermal conductivity compared to plastic, making them suitable for applications that require heat dissipation or thermal management. This makes aluminum a preferred choice for products such as heat sinks or electronic enclosures. However, it's important to note that aluminum sheets may not always be the best alternative to plastic. Plastic offers certain advantages such as being lightweight, flexible, and cost-effective, which makes it more suitable for applications that require these properties. Additionally, plastic can be molded into complex shapes, making it preferable for certain designs. In conclusion, aluminum sheets can be an effective alternative to plastic in certain applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity are advantageous. However, the choice between aluminum and plastic ultimately depends on the specific requirements and constraints of the application at hand.

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. Aluminum sheets should be stored in a clean and dry area to prevent any moisture absorption or corrosion. They should be kept in a well-ventilated space to avoid the buildup of any potentially harmful gases. It is important to stack the sheets properly, with adequate support and spacing, to prevent any bending or deformation. Additionally, aluminum sheets should be protected from direct sunlight to avoid any discoloration or fading. It is recommended to cover them with a suitable material, such as a plastic sheet or tarp, to provide an extra layer of protection. Proper storage conditions will help maintain the quality and integrity of the aluminum sheets for their intended use.

- Q: Are aluminum sheets suitable for chemical storage applications?

- Yes, aluminum sheets are suitable for chemical storage applications. Aluminum is known for its excellent corrosion resistance, making it ideal for storing a wide range of chemicals. It forms a naturally occurring oxide layer on its surface, which provides a protective barrier against moisture and chemicals. Additionally, aluminum sheets are lightweight and easy to handle, making them convenient for storage purposes. However, it is essential to consider the specific chemical being stored and consult with experts to ensure compatibility with aluminum. Some highly corrosive or reactive chemicals may require alternative storage materials.

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q: What is the typical electrical conductivity of aluminum sheets?

- The typical electrical conductivity of aluminum sheets is around 35.0 to 45.0 MS/m (mega siemens per meter) or 35,000 to 45,000 S/m (siemens per meter). Aluminum is known for its excellent electrical conductivity, which is approximately 61% of the conductivity of copper. This makes aluminum a popular choice for various electrical applications, such as wiring, power transmission lines, electrical busbars, and electrical equipment components. The conductivity of aluminum allows for efficient and reliable flow of electric current, making it a valuable material in the electrical industry.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

Send your message to us

Aircraft Aluminum Sheets 025 5x10 for Metal Roofing System Aluminium Panels Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords