Aluminum Sheets 5x10 025 - Aluminium Profile for Doors and Windows Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

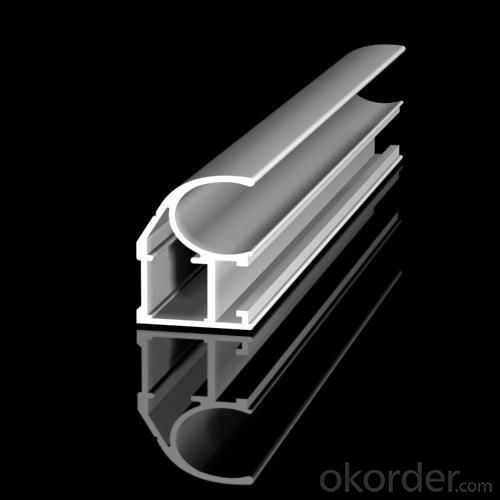

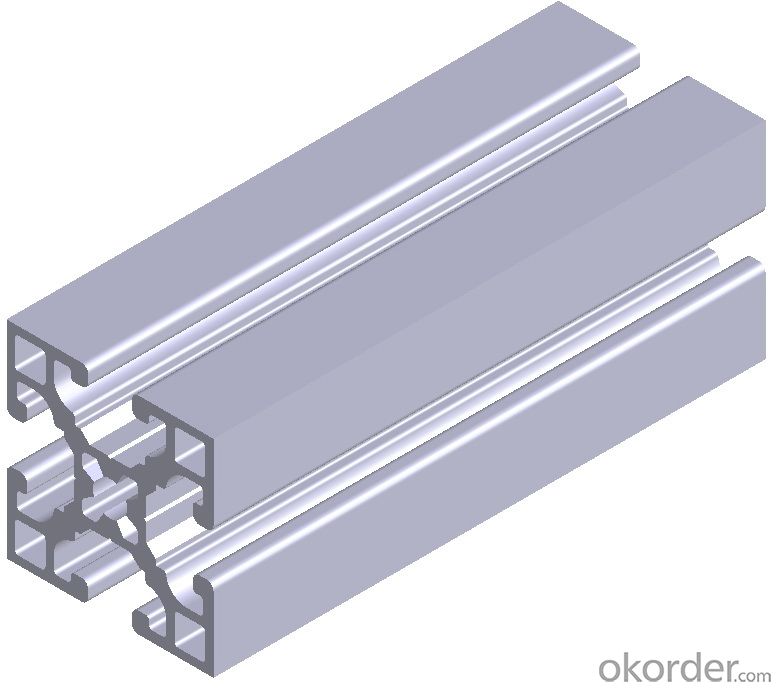

Structure of Aluminium Profile for Doors and Windows Parts Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Doors and Windows Parts:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

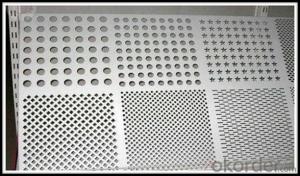

Images of Aluminium Profile for Doors and Windows Parts:

Aluminium Profile for Doors and Windows Parts Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it a popular choice for constructing bus bodies. Its high strength-to-weight ratio allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum can be easily molded and shaped, enabling manufacturers to design buses with unique and modern aesthetics.

- Q: A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this alloy?

- This Site Might Help You. RE: Analysis of a Magnesium-Aluminum Alloy? A 0.250-g sample of a magnesium-aluminum alloy dissolves completely in an excess of HCl (aq). When the liberated H2 is collected over water at 29 C and 752 torr, the volume is found to be 311 mL. The vapor pressure of water at 29 C is 30.0 torr. What is the mass percentage of aluminum in this...

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: What the glue of L solidified aluminum and fast acrylic plate, solid glue?

- If you only need sticky sticks and low marks, you can choose N-906AB glue or KD-855 quick drying metal glue

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are suitable for manufacturing kitchen utensils. Aluminum is lightweight, durable, and has excellent heat conductivity, making it an ideal material for kitchen utensils such as pots, pans, and baking sheets. Additionally, aluminum is resistant to corrosion and easy to clean, making it a popular choice for food preparation and cooking purposes.

- Q: What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- As long as it is spray paint, adhesion is not the same, if you want to firm, it is better to paint

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- This is the major topic of research for many commercial companies which prepare Oven and Grill cleaning products. The carbon itself is bound to the metal with denatured (carbonized) fat or oil molecules. These are generally effected only by very strong bases such as Sodium hydroxide (lye) which will react with aluminum and cause discoloration and chemical pitting. Mechanical removal using sharp blades or soft metal bristle brushes will work, but requires much labor. Steel wool is also used, but removes some of the metal from the surface of the pans. Special electrical devices have been used with success, but tend to slowly wear away the top layer of aluminum. Professional cooks ignore the problem by replacing aluminum with stainless steel pans. Home and do-it your-selfers tend to allow the buildup until everything sticks and then replace the pans. There has been a few who have seasoned their aluminum pans in a fashion similar to cast iron with mixed results. If this is for pizza pans for your restaurant, I suggest soaking the pans overnight in a strong solution of Dawn Dish-washing Liquid and then taking the pans to a steam car wash to remove the detergent.

- Q: What are the different bending techniques for aluminum sheets?

- Aluminum sheets can be bent using various techniques. Some commonly used techniques include: 1. Air bending: By applying force with a punch, the sheet bends in a straight line. The degree of bending depends on the force exerted. 2. Bottom bending: In this method, the sheet is clamped between a bottom tool and a die. A punch is then used to apply force from the top, resulting in a precise and consistent bend angle. 3. Coining: This technique involves bending the sheet with a punch and die, but with significantly higher force compared to other methods. The result is a crisp and sharp bend with minimal springback. 4. Rotary bending: The sheet is gradually bent around a rotating bending roll, which applies pressure to achieve a smooth bend. 5. Roll bending: Large sheets or cylindrical shapes are formed by passing the aluminum sheet through a series of rollers that gradually bend it to the desired shape. 6. Press braking: A versatile technique that utilizes a press brake machine consisting of a punch, die, and back gauge. This allows for precise and repeatable bends. Each technique has its own advantages and limitations, and the choice depends on factors like the desired bend angle, sheet thickness, and final product shape. It is crucial to select the appropriate technique to achieve the desired result and prevent any defects or damage to the aluminum sheet.

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

- Q: Iron is extracted from iron oxide by displacement with carbon.But aluminum is not extracted from aluminium oxide using displacement by carbon. Suggest a reason for this.

- Well, de facto because the heat of formation of aluminum oxide is so much greater than the heat of formation of iron oxide. If you're looking for something more mechanistic, find Al and Fe in the periodic table. Al and Fe are in different rows, and Fe is larger than Al, so although Al+3 and Fe+3 have the same charge, oxygen bonds less strongly to Fe+3 than to Al+3 because it's further away from the nucleus of Fe. Al+3 has no outer shell electrons at all; 3s, 3p, and 3d subshells are all empty. It's effectively a charged sphere with nothing to interfere with bonding. Fe+3 (as in hematite, Fe2O3) is larger, has filled 3s and 3p subshells, and a half-filled 3d subshell. That 3d electron density projects pretty far out into space, holding oxygen at arms length. Aluminum has no electron density in 3d orbitals, so oxygen can tuck in nice and tight and get a good grip. Any of these hit the mark? I don't know what background you're bringing to this question.

Send your message to us

Aluminum Sheets 5x10 025 - Aluminium Profile for Doors and Windows Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords