Mill Finished Aircraft Aluminum Sheets 025 5x10 for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

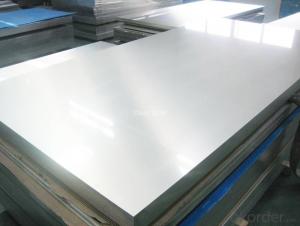

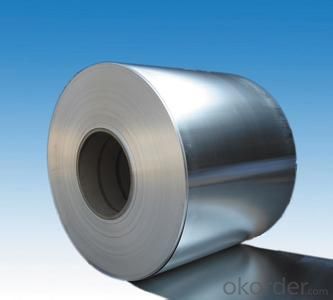

1.Structure of Mill Finished Aluminium Coils for Building Materials

Mill Finished Aluminium Coils for Building Materials is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils for Building Materials

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

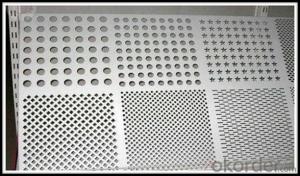

3. Image of Mill Finished Aluminium Coils for Building Materials

4. Product Specification of Mill Finished Aluminium Coils for Building Materials

| Alloy | Temper | Thickness | Width | Coil Weight |

| AA1100 | H18 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS-5TONS |

5.FAQ of Mill Finished Aluminium Coils for Building Materials

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: why is it gd and what are common aluminium compounds??? thx

- It's quite expensive to make aluminum, whereas it's quite cheap to melt it down and reuse it.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets may differ due to various factors including the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Typically, aluminum exhibits a high reflectivity, particularly in the visible light spectrum, and can effectively reflect approximately 80% to 90% of visible light. This attribute makes it widely used for creating reflective surfaces, mirrors, and various lighting applications. However, it is important to acknowledge that the precise reflectivity of 101 aluminum sheets can vary due to specific manufacturing processes or variations in the material properties.

- Q: Can aluminum sheets be used for boat building?

- Yes, aluminum sheets can be used for boat building. Aluminum is a popular material choice for boat construction due to its lightweight nature, durability, and resistance to corrosion. Aluminum sheets are commonly used in the construction of small recreational boats, larger yachts, and even commercial vessels. They offer several advantages such as being easy to work with, providing excellent strength-to-weight ratio, and requiring minimal maintenance. Additionally, aluminum boats are known for their superior buoyancy, stability, and fuel efficiency. Overall, aluminum sheets are a suitable and reliable option for boat building.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: This question asks for the current market price of aluminum sheets.

- <p>The price of aluminum sheets in the market can vary significantly based on factors such as grade, thickness, quantity, and market demand. As of my last update, the price per ton of aluminum was fluctuating around $2,000 to $3,000 USD, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with suppliers or commodity exchanges, as prices can shift daily due to global economic conditions and supply chain dynamics.</p>

- Q: Can aluminum sheets be used for chemical reactors?

- Certain applications allow for the use of aluminum sheets in chemical reactors. Aluminum possesses excellent corrosion resistance, rendering it appropriate for diverse chemical reactions. Nevertheless, it is crucial to take into account the nature of the chemicals employed and their potential reactivity with aluminum. In highly acidic or alkaline environments, aluminum's reactivity and susceptibility to corrosion should be duly recognized. Furthermore, specific gases or elevated temperatures may render aluminum unsuitable for reactions. In such instances, alternative materials such as stainless steel or glass-lined reactors might prove more fitting.

- Q: What is the typical thermal conductivity of aluminum sheets?

- The typical thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin (W/mK). This high thermal conductivity makes aluminum an excellent heat conductor, which is why it is commonly used in applications where heat transfer is important, such as in heat sinks, power transmission lines, and cooking utensils.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers due to their excellent thermal conductivity, lightweight nature, and corrosion resistance.

- Q: Can the aluminum sheets be custom-cut to specific dimensions?

- Yes, the aluminum sheets can be custom-cut to specific dimensions.

Send your message to us

Mill Finished Aircraft Aluminum Sheets 025 5x10 for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords