6061 Aluminum Embossed Sheet for Roofing Application - 5-Pack

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

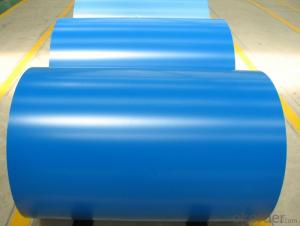

Structure of Aluminium Embossed Sheet for Roofing Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Embossed Sheet for Roofing Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

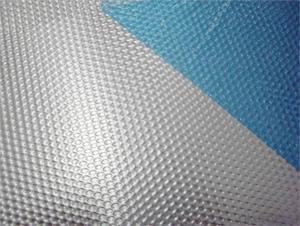

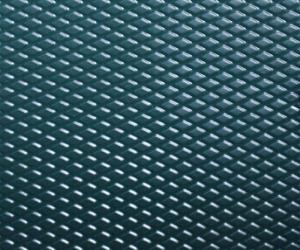

Images of the Aluminium Embossed Sheet for Roofing Application:

Aluminium Embossed Sheet for Roofing Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepaited Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on factors such as alloy composition, tempering, and thickness. However, generally, aluminum sheets have a moderate impact strength, making them suitable for many applications that require resistance to impact and denting.

- Q: What are the standard dimensions of aluminum sheets?

- The specific industry and application determine the varying standard dimensions of aluminum sheets. However, there are commonly available sizes that are commonly used. For general purposes, aluminum sheets are commonly found in dimensions of 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These dimensions, often referred to as "full sheets," are widely used in construction, manufacturing, and signage industries. Aside from full sheets, smaller sizes of aluminum sheets are also available, such as 2 feet by 4 feet (609mm x 1219mm) and 2 feet by 8 feet (609mm x 2438mm). These smaller sizes are commonly used for DIY projects, crafts, and hobbies. It is important to note that although these dimensions are standard, aluminum sheets can be custom cut to meet specific sizes and shapes for individual project requirements. This provides greater flexibility and versatility across various industries. Ultimately, the choice of aluminum sheet dimensions depends on the specific needs of the project, industry standards, and personal preferences.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- the fourth statement.

- Q: What are aluminum sheets used for?

- Aluminum sheets have a wide range of uses due to their unique properties and versatility. One of the most common applications is in construction, where aluminum sheets are used for roofing, siding, and cladding. Their lightweight nature, corrosion resistance, and durability make them ideal for these purposes. Aluminum sheets are also widely used in the transportation industry. They are commonly utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. Additionally, aluminum sheets are utilized in the production of trailers, truck bodies, and shipping containers, as they provide a lightweight yet sturdy solution. Another important application of aluminum sheets is in the manufacturing of consumer products. They are used for making household appliances, cookware, and electronics due to their excellent thermal conductivity and resistance to rust and corrosion. Aluminum sheets are also employed in the production of signage, billboards, and displays due to their ability to withstand various weather conditions. In the packaging industry, aluminum sheets play a crucial role. They are commonly used for making cans, foils, and lids due to their impermeability to light, moisture, and oxygen. Aluminum sheets help preserve the freshness and quality of food and beverages. Furthermore, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Aluminum sheets are also used in the production of heat exchangers, solar panels, and electrical conductors due to their thermal and electrical conductivity. In summary, aluminum sheets are utilized in construction, transportation, consumer products, packaging, and various industrial applications due to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The cost of 101 aluminum sheets may fluctuate based on various factors like market conditions, demand, and supply. Nonetheless, in general, 101 aluminum alloy is regarded as one of the more affordable choices among aluminum alloys. It is a popular option due to its relatively low price and satisfactory overall performance. When compared to other aluminum alloys, particularly high-strength alloys like 7075 or 6061, 101 aluminum sheets tend to be less expensive. This is because 101 aluminum is a relatively uncomplicated alloy with a lower content of alloying elements, resulting in lower production costs. However, it is important to note that the price difference between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as sheet thickness, size, and quantity can also impact the final price. Therefore, it is always advisable to consult suppliers or manufacturers to obtain the most accurate and up-to-date pricing information for 101 aluminum sheets in comparison to other aluminum alloys.

- Q: What is the use?

- The three and 3000 series aluminum on behalf of 300330033A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 written columns, is a commonly used alloy series.The four and 4000 series aluminum aluminum on behalf of 4A014000 series belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceThe five and 5000 Series 5052.5005.5083.5A05 series.5000 series aluminum plate belongs to the representative of the more commonly used aluminium alloy series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing. Oxidation belongs to one of the more mature aluminum series in China 5000 series aluminum plate.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a lightweight and durable material that is commonly used in the food industry. It is non-toxic, non-reactive, and does not release any harmful chemicals when it comes into contact with food. Aluminum sheets are also easy to clean and maintain, making them a popular choice for food preparation surfaces in both commercial kitchens and home kitchens. Additionally, aluminum has excellent heat conductivity, allowing for even cooking and baking. However, it is important to note that aluminum can react with acidic or salty foods, causing a metallic taste. To prevent this, it is recommended to use a layer of parchment paper or silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: What does aluminum plate "H12" mean?

- The utility model is suitable for the products with stable mechanical performance after work hardening, heat treatment or heat treatment in the process of processing. The H3 state is only applicable to the alloy gradually softening at room temperature (unless stabilized). H4 - the state of work hardening and coating treatment. The utility model is suitable for products with incomplete annealing after work hardening and after coating treatment.The second digits behind the H indicate the degree of work hardening of the product. The number 8 indicates a hard state. The minimum tensile strength of a hx8 is specified by the sum of the minimum tensile strength of the o state and the specified strength difference. For the states between O (annealed) and hx8 States, the numbers from 1 to 7 should be added after the HX code, adding the number 9 to the HX to indicate a more severe state of hardening than the hx8.

Send your message to us

6061 Aluminum Embossed Sheet for Roofing Application - 5-Pack

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords