4x8 Sheets of Aluminum for Sale - 1100-h124 Aluminium Sheet and Aluminium Slab in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

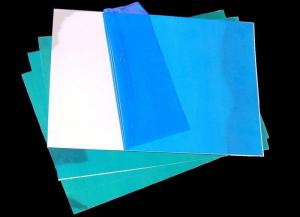

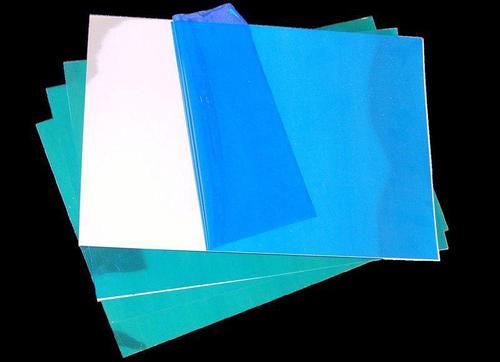

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: What are the environmental benefits of using aluminum sheets?

- The usage of aluminum sheets is associated with numerous environmental advantages. To begin with, aluminum is a highly recyclable substance, meaning it can be recycled repeatedly without losing its quality or properties. This diminishes the need for mining and extracting new aluminum ore, which can lead to deforestation, destruction of habitats, and pollution of water and air. The recycling of aluminum sheets also demands much less energy compared to the production of new ones, resulting in reduced emissions of greenhouse gases and a smaller carbon footprint. Moreover, aluminum sheets are lightweight, making them a more sustainable option in comparison to materials like steel or plastic. Their utilization in various industries like automotive and aerospace can aid in reducing the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This becomes particularly crucial in the context of climate change and the necessity to decrease our reliance on fossil fuels. Additionally, aluminum is resistant to corrosion, durable, and long-lasting, making it a sustainable choice for various applications. Its durability lessens the need for frequent replacements, thereby reducing waste generation. Furthermore, aluminum sheets can be employed in construction to enhance insulation, resulting in energy savings and diminished emissions of greenhouse gases. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This renders it a safe material option for various applications, including food packaging and medical equipment. To summarize, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By selecting aluminum sheets over other materials, we can contribute to the reduction of resource extraction, energy consumption, emissions of greenhouse gases, and generation of waste, while promoting a more sustainable and eco-friendly future.

- Q: What are the common sizes of aluminum sheet?

- Common sizes of aluminum sheets vary depending on the specific requirements and industry applications. However, some standard sizes are commonly available in the market. These sizes typically range from 0.025 inches to 0.125 inches in thickness and can come in various widths and lengths. Some common width options include 36 inches, 48 inches, and 60 inches, while the length can range from 96 inches to 144 inches. Additionally, aluminum sheets can also be found in smaller sizes, such as 12 inches by 24 inches or 24 inches by 24 inches, which are often used for smaller projects or crafts. It is important to note that custom sizes can also be obtained through specialized aluminum sheet suppliers.

- Q: And isn't aluminum extremely bad for ones health?

- Antiperspirant does two things. It kills sanitizes the area so it kills resident bacteria that eat the oils and secretions in the skin and produce odor. The aluminum compounds plug the pores and prevent sweat secretion. But be careful, aluminum has been implicated in Alzheimers disease.

- Q: Is it possible to use aluminum sheets as a material for exterior siding or cladding on buildings?

- <p>Yes, aluminum sheets are commonly used for siding or cladding due to their durability, lightweight, and resistance to corrosion. They are low maintenance, can be easily shaped, and come in various colors and finishes. Aluminum's resistance to weathering and its ability to withstand temperature extremes make it a popular choice for both residential and commercial buildings.</p>

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Bass Tracker Aluminum Boats

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: How do you prevent oxidation of aluminum sheets?

- To avoid oxidation of aluminum sheets, several techniques can be utilized. One commonly used method is to apply a protective coating or finish on the surface of the aluminum sheets. This coating acts as a barrier between the aluminum and the external environment, preventing the metal from reacting with oxygen and forming an oxide layer. There are various types of coatings available for this purpose, such as anodizing, painting, and powder coating. Anodizing involves creating a controlled oxide layer on the aluminum surface through electrolysis. This oxide layer is highly resistant to corrosion and provides excellent protection against oxidation. Painting and powder coating, on the other hand, involve applying a layer of paint or powdered polymer to the aluminum surface. These coatings create a physical barrier that shields the metal from oxygen and moisture. Another effective approach to prevent oxidation is by using aluminum alloys that have enhanced corrosion resistance. These alloys are specifically designed to have a higher resistance to oxidation and can withstand exposure to harsh environments without forming a significant oxide layer. In addition to coatings and alloy selection, proper storage and handling practices play a crucial role in preventing oxidation. It is important to store aluminum sheets in a clean, dry, and well-ventilated area to minimize exposure to moisture and corrosive elements. Contact with acidic or alkaline substances should be avoided, as they can accelerate the oxidation process. Regular cleaning and maintenance of aluminum sheets also help prevent oxidation by removing any contaminants that could promote corrosion. In summary, preventing oxidation of aluminum sheets involves a combination of protective coatings, appropriate alloy selection, and proper storage and handling practices. By implementing these measures, the lifespan and durability of aluminum sheets can be significantly improved.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

- Q: Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is a widely used material in the electronics industry due to its excellent conductivity, low weight, and high durability. It is commonly used for various applications such as housing for electronic components, heat sinks, and electrical connectors. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of electronic devices. Additionally, aluminum is a cost-effective material, making it an attractive choice for manufacturers in the electronics industry.

Send your message to us

4x8 Sheets of Aluminum for Sale - 1100-h124 Aluminium Sheet and Aluminium Slab in Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords