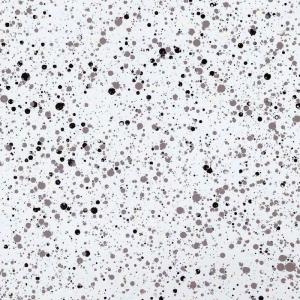

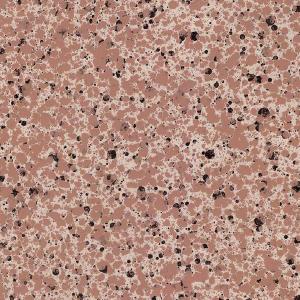

Chocolate Brown Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.flat mill finished surface.

2.without oxidation and scratch.

3.high quaity and the best service.

4.long-term of cooperation

Plain Aluminium sheet

1.Alloy : 1100 ,1050,1060 ,3003 ,5052,5005 ,5754,6061 ,8011

2.Temper: H12,h14,h16,h18,h24,h26,O

3.Thickness: form 0.12mm to 20mm ,

4.Size : ,1000 mm X 2000mm ;1220 mm x 2440 mm

5.Surface filmed with pvc or paper inter to profect the surface .

6.Packing :seaworthy wooden pallets

- Q: Aluminum metal reacts with hydrochloric acid, HCl, to form hydrogen gas (H2) and a solution of aluminum chloride. Write and balance the equation. Can someone help I just dont get this Al2 + 6HCl → 3H2 + 2AlCl3 Al2 + 2HCl → H2 + 2AlCl 2Al + 6HCl → 3H2 + 2AlCl3 Al + 2HCl → H2 + AlCl2 6Al + 2HCl → H2 + 2Al3Cl

- 2NH4Cl+Ca(OH)2-CaCl+2NH3+2H2O 18 Zn+2Cl-ZnCl2+H2 19 F2+2NaCl-2NaF+Cl2 20 CaO+SO2-CaSO3 21 2CaSO3+O2-2CaSO4 22 2HgO-2Hg+O2 23 CH3OH-CO+2H2 24 2KNO3-2KNO2+O2 you put the question in wrong section. Answer the others by yourself. I have given lots of examples there.

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: How do aluminum coils perform under high-temperature applications?

- Aluminum coils are renowned for their exceptional resistance to heat and their ability to perform well in applications that involve high temperatures. With a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum coils can endure and function efficiently even when exposed to elevated temperatures. The high thermal conductivity of aluminum allows for the rapid transfer of heat away from the coil, preventing overheating and potential damage. This characteristic enables aluminum coils to effectively dissipate heat, resulting in improved thermal management and enhanced performance in environments with high temperatures. In addition, aluminum coils possess good corrosion resistance, which is crucial in situations where heat and moisture are present. The naturally occurring oxide layer on the surface of aluminum acts as a protective barrier against corrosion, ensuring the durability and reliability of the coil, even in challenging conditions. Furthermore, aluminum coils are lightweight and highly malleable, making them easy to install and integrate into a variety of systems and applications. This versatility renders them suitable for a wide range of high-temperature applications, including heat exchangers, automotive components, HVAC systems, and electrical devices. However, it is important to note that subjecting aluminum to extreme temperatures beyond its melting point can cause the material to weaken or deform. Therefore, it is essential to carefully consider the specific temperature requirements and limitations of the aluminum coil before implementing it in a high-temperature application.

- Q: What is the lifespan of aluminum coils?

- The lifespan of aluminum coils can vary depending on various factors such as the quality of the aluminum, the manufacturing process, the environmental conditions they are exposed to, and the maintenance provided. However, on average, aluminum coils can last anywhere from 15 to 30 years. With proper care and regular maintenance, including cleaning and inspection, aluminum coils can potentially have an extended lifespan. It is important to note that regular maintenance and servicing by professionals can help identify any issues early on, allowing for timely repairs or replacements, ultimately prolonging the lifespan of aluminum coils.

- Q: This question asks for the weight of a single layer of an aluminum coil, which can vary based on its dimensions.

- <p>The weight of a single layer of an aluminum coil depends on its thickness, width, and length. To calculate the weight, you can use the formula: weight = volume 脳 density. The density of aluminum is approximately 2.7 grams per cubic centimeter. If you know the dimensions of the coil, you can calculate its volume and then multiply by the density to find the weight. For example, if the coil has a thickness of 0.1 mm, a width of 1 meter, and a length of 100 meters, the volume would be 0.1 liters or 100 cubic centimeters, and the weight would be approximately 270 kg. However, without specific dimensions, it's impossible to provide an exact weight.</p>

- Q: Are aluminum coils suitable for low-maintenance roofing applications?

- Yes, aluminum coils are suitable for low-maintenance roofing applications. Aluminum is highly resistant to corrosion, lightweight, and durable, making it an ideal material for roofing. It requires minimal maintenance, as it does not rust or rot like other metals. Additionally, aluminum roofs are known for their longevity and ability to withstand harsh weather conditions, further reducing the need for maintenance.

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: Are there any specific installation requirements for aluminum coils?

- Yes, there are specific installation requirements for aluminum coils. These requirements typically include proper handling, storage, and positioning of the coils to ensure they remain undamaged during installation. Additionally, proper cleaning, lubrication, and sealing of the coil connections are commonly recommended to maintain optimal performance and prevent leaks. It is important to consult the manufacturer's guidelines and follow industry standards when installing aluminum coils to ensure a successful and efficient installation.

- Q: What are the insulation options available for aluminum coils?

- Depending on the specific requirements and applications, there are various insulation options available for aluminum coils. Some commonly used insulation options include: 1. Foam Insulation: Aluminum coils are often insulated with foam, which provides excellent thermal insulation properties. Foam insulation comes in different forms, such as rigid foam boards or flexible foam sheets, and can be easily cut and fitted around the coils. 2. Fiberglass Insulation: Another popular choice for aluminum coil insulation is fiberglass. It consists of thin glass fibers woven together to create a blanket-like material. Fiberglass insulation is lightweight, easy to install, and offers good thermal and acoustic insulation. 3. Mineral Wool Insulation: Mineral wool insulation is made from natural or synthetic minerals that are melted and spun into fine fibers. It is known for its excellent fire-resistance properties and provides effective thermal insulation for aluminum coils. 4. Reflective Insulation: To reflect radiant heat away from the aluminum coils, reflective insulation is used. It typically consists of a layer of aluminum foil laminated to a layer of fiberglass or plastic bubble wrap. Reflective insulation is particularly effective in warmer climates where reducing heat gain is a priority. 5. Vapor Barrier Insulation: Vapor barrier insulation is applied to prevent moisture transfer through the insulation material. It is often used as a coating or film over the insulation, creating a barrier against water vapor and reducing the risk of condensation buildup on the aluminum coils. When selecting the appropriate insulation option for aluminum coils, it is important to consider factors such as thermal conductivity, fire resistance, moisture resistance, and installation requirements. Consulting with a professional or referring to manufacturer guidelines can help determine the most suitable insulation option for specific coil applications.

Send your message to us

Chocolate Brown Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords