Chocolate Brown Aluminum Coil - Aluminium Prepainted PVDF with 10μ 1100 H18

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

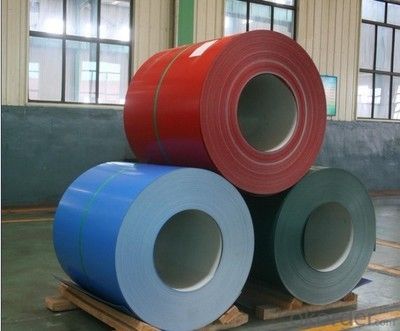

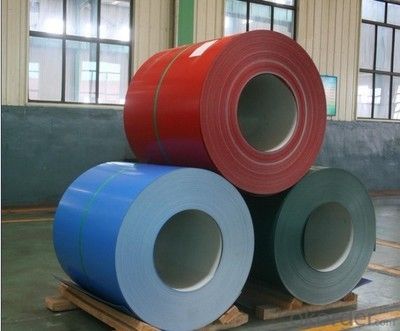

Structure of Aluminium Prepainted PVDF with 10μ 1100 H18 Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted PVDF with 10μ 1100 H18:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Prepainted PVDF with 10μ 1100 H18:

Aluminium Prepainted PVDF with 10μ 1100 H18 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the common sizes of aluminum coils?

- The common sizes of aluminum coils can vary depending on the specific industry and application. However, some commonly used sizes include widths ranging from 36 inches to 72 inches, with thicknesses typically ranging from 0.019 inches to 0.125 inches.

- Q: which metal is very common today and which one will be most common in future. steel or aluminum

- Steel is definitely most common engineering material. Aluminum is lighter and is finding increasing use in transport industry due to energy cost and global warming. It is unlikely that it will surpass steel ever in future due to higher cost. Magnesium has the potential of growing to beat both of these metals (magnesium is more abundant on earth than either aluminum or iron (steel).

- Q: What do you think of the stainless steel with copper and aluminum core cookware? And what's a good brand?

- Stainless exterior with a conductive core is excellent. I have Lagostina and have been very happy with it. Look at the expensive brands and then look for a deal on one of those, or find a cheaper brand with most of the good features, principle one to look for is a good thick bottom.

- Q: is there an anti-perspirant without aluminum in it for men? i saw there was a female question for it but i need a male one xD. something that you can find at your local wal-mart or such.

- The crystal brand work pretty well for both sexes, but they work better if you shave your pits. I like Tom's Natural brand.... just try your local healthfood store or the natural section of the supermarket there will be a few brands to choose from.

- Q: Can aluminum coils be used in telecommunications infrastructure?

- Yes, aluminum coils can be used in telecommunications infrastructure. Aluminum is commonly used in various components of telecommunications infrastructure, including cables, connectors, and antennas. It is preferred for its lightweight, durable, and corrosion-resistant properties, making it suitable for outdoor installations. Additionally, aluminum coils provide excellent conductivity, ensuring efficient transmission of signals in telecommunications systems.

- Q: Are there any specific regulations for the transportation of aluminum coils?

- The transportation of aluminum coils is subject to specific regulations aimed at guaranteeing their safe handling and transport in order to prevent any accidents or damage. These regulations encompass various key requirements: 1. Packaging: To avoid any shifting, damage, or falling during transportation, aluminum coils must be securely packaged in appropriate containers. This may involve the utilization of strapping, banding, or shrink-wrapping techniques. 2. Weight limitations: Depending on the mode of transportation employed, there are weight restrictions in place for the transportation of aluminum coils. These limitations are implemented to ensure the stability and safety of the vehicle during transit. 3. Loading and unloading procedures: It is essential to follow proper loading and unloading procedures to minimize the risk of coil damage and to ensure worker safety. This may necessitate the use of specialized equipment like cranes or forklifts. 4. Regulations for hazardous materials: In certain instances, aluminum coils may be considered hazardous materials due to their flammability or other characteristics. In such cases, additional regulations and requirements may be applicable, such as appropriate labeling, documentation, and handling procedures. 5. Transportation permits: Depending on the size, weight, and destination of the aluminum coils, specific permits or licenses may be necessary for their transportation. These permits ensure compliance with local, state, and federal regulations. It is crucial for companies involved in the transportation of aluminum coils to possess awareness of and adhere to these regulations to ensure the secure and efficient transport of the coils. Failure to comply with these regulations can result in fines, penalties, or even legal ramifications.

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils can vary depending on the specific industry and application. However, in general, the standard widths of aluminum coils range from 12 inches (30.48 cm) to 60 inches (152.4 cm). These standard widths are commonly used in various industries such as construction, transportation, and manufacturing. It is important to note that customized widths are also available in the market to cater to specific project requirements.

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, corrosion resistance, and lightweight nature. It can be easily formed into various shapes and sizes, making it suitable for different types of signage such as outdoor signs, billboards, trade show displays, and more. Additionally, aluminum coils offer excellent weather resistance, ensuring that the signage remains intact and vibrant even in harsh environmental conditions. The versatility and longevity of aluminum make it a preferred choice for signage applications in various industries.

- Q: This question asks for methods to determine whether an aluminum coil is made from recycled material.

- <p>Determining if an aluminum coil is made from recycled material can be challenging without specific testing, as recycled and virgin aluminum can look identical. However, there are a few indicators: 1) Look for certification or labels on the coil indicating it's made from recycled material. 2) Check with the supplier for documentation or a certificate of analysis that confirms the material's origin. 3) Analyze the coil's composition; recycled aluminum may have slight variations in purity or alloy composition. 4) Use spectrographic analysis to determine the exact composition of the aluminum, which can sometimes reveal if it's recycled. Ultimately, transparency from the supplier is key to confirming the source of the aluminum.</p>

Send your message to us

Chocolate Brown Aluminum Coil - Aluminium Prepainted PVDF with 10μ 1100 H18

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords