Perforated PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

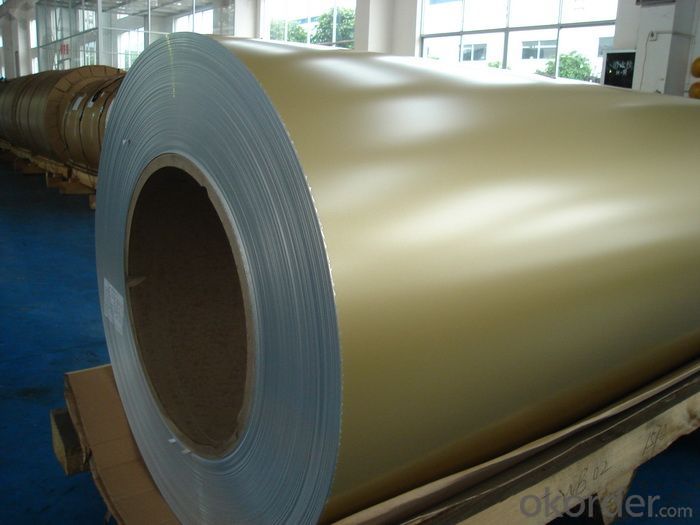

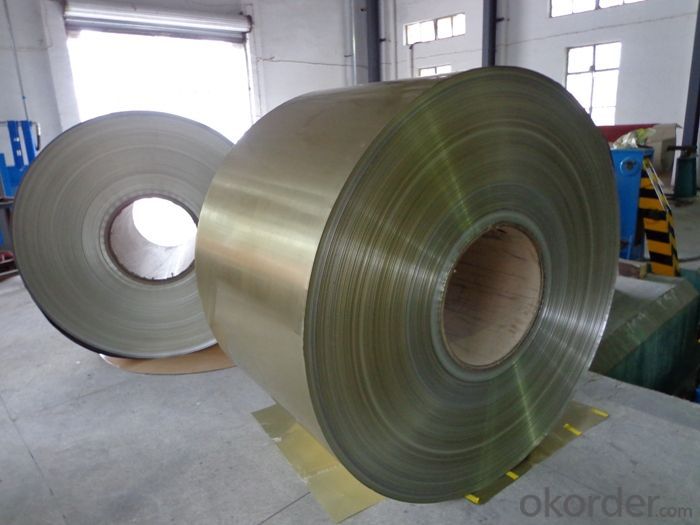

1.Structure of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

We normally used PVDF coated aluminum coils 3003 for building materials.

3003 is very good in high strength, corrosion resistance, high weather resistance and other characteristics.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. PVDF Coated Aluminum Coils 3004 Alloy for Building Materials Images

4. Specification of PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I need help with 3 main ideas for a aluminum and copper chloride lab. I need evidence for these 3 ideas that what happened was a chemical reaction.

- Aluminum metal usually has a passivating layer of Al2O3 which prevents aluminum from reacting with Cu2+ ions. Al won't react with CuSO4(aq), for instance. But if NaCl is added then it will. It is the effect of the chloride ion that makes the reaction go. Al2O3(s) + 8Cl-(aq) + 3H2O -- 2[AlCl4]^- + 6OH- Once the passivating layer is dissolved, then aluminum metal is available to react with chloride ion. You see the aluminum metal disappear, while dark red Cu metal is formed, along with the decrease in the blue color due to hydrated copper ions, [Cu(H2O)6]^2+. In addition, aluminum metal has a side-reaction with water to form hydrogen gas. Therefore, you will observe that as gas is given off. Not only that, the temperature of the solution will increase. 2Al(s) + 2OH- + 6H2O -- 2[Al(OH)4]- + 3H2(g) In summary. There are four indicators of a chemical reaction. 1. The formation of a precipitate 2. The evolution of a gas 3. A color change 4. A temperature change. All four indicators are observed. Solid Cu metal is formed. Hydrogen gas is given off. The color of the solution changes from blue to colorless, and the temperature increases.

- Q: Is it possible to construct a portable speaker or speaker docking station using aluminum coils?

- <p>Yes, you can use aluminum coils in the construction of a portable speaker or speaker docking station, but they are not the primary component. Aluminum coils can be used in the speaker's electromagnetic parts, such as in the voice coil of the speaker driver or in the transformer of a docking station. However, the main components of a speaker include a diaphragm, voice coil, magnet, and enclosure, while a docking station would require a connector for the device, an amplifier, and possibly additional circuitry. The aluminum coil's role is to facilitate the magnetic field interaction with the voice coil, which converts electrical signals into sound waves. It's essential to consider the entire design and other necessary components when building such devices.</p>

- Q: We are working on a new aluminum fixture. It is basically an aluminum spine with many 6061-T6 pins sticking out. Currently we drill the holes inside the spine and hammer the 5/32 6061-T6 pins inside. Is there anyway to cast aluminum with many 6061-T6 pins embedded (they will stick out after the casting)?

- How long are the pins? have you considered casting the pins along with the rest of the part? or is that what you are asking, it sounds, like you are talking about loading pins into the mold and having the cast spine bond with them. What casting process are you using, or are you even using a casting now, or is the spine currently rolled or extruded shapes? As mentioned on RCM, the pins will no longer be T6 after casting, if you need the T6 temper the part will have to be heat treated.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a common material choice for evaporator coils in refrigeration systems due to its excellent heat transfer properties, corrosion resistance, and lightweight nature.

- Q: I'm doing a project on aluminum and this is the one thing i can't find. Also will it rust, tarnish or corrode?

- Aluminum is actually highly reactive. Under normal conditions, its outer layer quickly forms a coating of aluminum oxide which is extremely hard and well-attached. This prevents any further corrosion or oxidation. Molten aluminum will react explosively with water; this is a well-known danger in the aluminum casting industry. Very finely powdered aluminum is pyrophoric (self-igniting in air) and is used as a component in flash powder and some solid rocket fuels.

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- In terms of weight, aluminum coils are considerably lighter than titanium coils. This is due to aluminum having a lower density than titanium, resulting in aluminum weighing less than titanium for the same volume. This quality makes aluminum coils highly favored in industries like aerospace and automotive where reducing weight is essential. On the other hand, titanium coils are renowned for their exceptional strength and excellent corrosion resistance, making them ideal for environments that prioritize durability. Ultimately, the decision between aluminum and titanium coils depends on the specific needs and compromises sought for a particular application.

- Q: This question asks about the environmental effects that aluminum coils may have on the environment.

- <p>The environmental impacts of aluminum coils are multifaceted. Aluminum production, particularly the extraction and refining process, consumes significant energy and can result in greenhouse gas emissions. The mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. However, aluminum coils are recyclable, which reduces their environmental footprint compared to non-recyclable materials. When recycled, aluminum saves up to 95% of the energy needed to produce new aluminum, reducing emissions and waste. Despite these benefits, improper disposal or incineration of aluminum can still contribute to pollution. Overall, the environmental impact of aluminum coils is complex, with both negative and positive aspects depending on production methods and waste management practices.</p>

- Q: How are aluminum coils transported and packaged?

- Aluminum coils are typically transported and packaged using wooden crates or pallets. The coils are securely strapped or bundled together to prevent movement during transit. They are then loaded onto trucks or shipping containers for transportation, ensuring they are well-protected to avoid any damage or deformation.

- Q: Can aluminum coils withstand extreme temperatures?

- Aluminum coils have gained a reputation for their remarkable capability to endure extreme temperatures. With a melting point of 660.32°C (1220.58°F), aluminum proves to be an ideal material for tasks demanding heat resistance. HVAC systems, for instance, frequently employ aluminum coils that are exposed to both high and low temperatures. Similarly, automotive radiators rely on aluminum coils to withstand elevated operating temperatures. Moreover, the outstanding thermal conductivity of aluminum enables efficient heat transfer away from the coil, further bolstering its ability to withstand extreme temperatures. All in all, aluminum coils stand as a dependable and long-lasting option for applications that necessitate resistance to severe temperature conditions.

- Q: Can aluminum coils be used for signage and display applications?

- Signage and display applications can utilize aluminum coils effectively. Aluminum, being a versatile and lightweight material, finds extensive usage in the signage industry. The ability to easily shape and resize aluminum coils makes them suitable for various signage and display purposes. When it comes to outdoor signs, such as billboards, building signs, and traffic signs, aluminum coils are commonly employed due to their exceptional resistance to weather and durability. They can endure harsh weather conditions like rain, snow, and UV exposure without undergoing rusting or fading. This quality makes them a reliable option for signage with long-lasting effects. Moreover, aluminum coils can be coated with various finishes like paint or powder coating to enhance their appearance and provide added protection against corrosion. This enables customization and branding opportunities, making aluminum coils appropriate for both functional and decorative signage. Regarding display applications, aluminum coils can be utilized to create exhibition stands, trade show displays, retail displays, and other promotional materials. Their lightweight nature facilitates easy transport, assembly, and disassembly, making them advantageous for portable displays. Additionally, aluminum coils can be easily printed on or laminated, enabling the incorporation of graphics and visuals to capture attention and convey messages effectively. All in all, aluminum coils are a versatile and resilient material suitable for a wide array of signage and display applications. Their ability to withstand weather, customizable finishes, and lightweight properties contribute to their popularity in the industry.

Send your message to us

Perforated PVDF Coated Aluminum Coils 3004 Alloy for Building Materials

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords