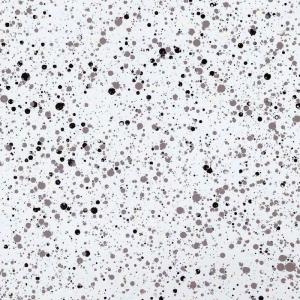

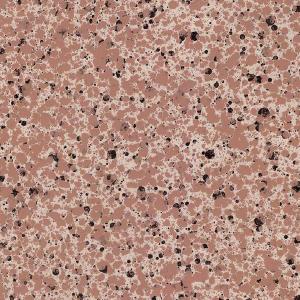

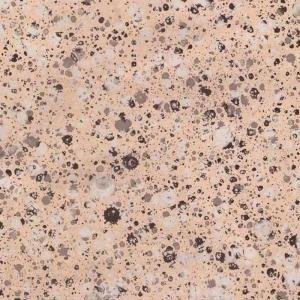

Royal Brown Marble Grain Aluminum Coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: How do aluminum coils contribute to lightweight transportation?

- The inherent properties and versatile applications of aluminum coils make them a significant contributor to lightweight transportation. Firstly, aluminum itself is a lightweight material, with a density one-third that of steel, making it perfect for constructing different transportation vehicle components like cars, airplanes, and trains. In terms of manufacturing aluminum coils, they are typically produced through a continuous casting and rolling process, resulting in a coil shape that is easy to transport and handle. Depending on the specific requirements of the transportation industry, these coils can be further processed into sheets, plates, or other forms. The lightweight nature of aluminum coils offers numerous advantages for transportation. Firstly, it reduces the overall weight of the vehicle, leading to improved fuel efficiency and reduced emissions. Lighter vehicles require less energy to move, resulting in cost savings and environmental benefits. Additionally, the reduced weight allows for increased payload capacity, enabling transportation companies to carry more goods or passengers without exceeding weight limitations. Furthermore, aluminum coils possess excellent corrosion resistance, ensuring the longevity of transportation vehicles even in harsh environments. This durability reduces maintenance and replacement costs, making aluminum a economically viable choice for lightweight transportation. Moreover, aluminum coils offer excellent formability and can be easily shaped into different designs. This flexibility in design allows manufacturers to create aerodynamic structures that further enhance fuel efficiency. Vehicles can be produced with reduced drag and improved performance, contributing to lightweight transportation. In conclusion, aluminum coils are crucial in lightweight transportation as they provide a lightweight, durable, and corrosion-resistant material. Their utilization in various transportation components helps reduce overall vehicle weight, improve fuel efficiency, increase payload capacity, and enhance aerodynamics. As the transportation industry continues to prioritize sustainability and efficiency, aluminum coils will continue to play a significant role in achieving these goals.

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: Are aluminum coils resistant to UV radiation?

- Yes, aluminum coils are generally resistant to UV radiation. Aluminum is a highly durable and corrosion-resistant material, and it has natural properties that make it resistant to the damaging effects of UV radiation. Unlike certain other metals, aluminum does not oxidize or deteriorate when exposed to sunlight for extended periods of time. This makes it an ideal choice for applications where UV exposure is a concern, such as outdoor structures, solar panels, and automotive components. However, it is important to note that while aluminum is resistant to UV radiation, it can still be subject to other forms of degradation if not properly protected or maintained.

- Q: How are aluminum coils used in electrical applications?

- Aluminum coils are widely used in various electrical applications due to their advantageous properties. These coils are primarily used in transformers, motors, and inductors. In transformers, aluminum coils are used to transfer electrical energy from one circuit to another. The coils are wound around a magnetic core, which helps in the efficient transfer of energy. Aluminum coils are preferred over copper coils in transformers due to their lower cost, lightweight nature, and excellent conductivity. Additionally, aluminum coils have a higher thermal conductivity, allowing for better heat dissipation, which is crucial in maintaining the efficiency and longevity of transformers. In motors, aluminum coils are used as the winding material for the stator. The stator is the stationary part of the motor, and the coils generate a magnetic field when an electrical current is passed through them. This magnetic field interacts with the rotating magnetic field generated by the motor's rotor, resulting in the rotation of the motor. Aluminum coils are preferred in motors due to their lightweight nature, which reduces the overall weight of the motor, making it more efficient. Inductors are another electrical component that utilizes aluminum coils. Inductors store electrical energy in the form of a magnetic field. When current flows through the coil, a magnetic field is created, which resists changes in the current. Aluminum coils are used in inductors due to their high electrical conductivity, which allows for efficient energy storage and release. Overall, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their usage in transformers, motors, and inductors contributes to the efficient and reliable operation of electrical systems.

- Q: This question asks for the various uses of aluminum coil within the construction industry.

- <p>Aluminum coil has several applications in construction due to its lightweight, durability, and resistance to corrosion. It is commonly used in roofing and siding materials for both residential and commercial buildings. Aluminum coil is also utilized in the manufacturing of window frames and doors due to its strength and ability to withstand harsh weather conditions. Furthermore, it is used in the production of heat exchangers and HVAC systems because of its thermal conductivity. Additionally, aluminum coil is employed in the construction of scaffolding and temporary structures due to its ease of handling and high strength-to-weight ratio. It also finds use in the fabrication of electrical conduits and cable trays because of its electrical conductivity and resistance to moisture.</p>

- Q: 1) Do you recycle aluminum (soda cans, etc.)?2) Why do or don't you recycle aluminum?3) Does it make a difference to the economy whether we recycle or not?4) Does it make a difference to the environment whether we recycle or not?5) What do you think would help people to recycle more? Such as a reward, information, resources, etc. Don't feel the need to limit responses. Thank you.

- no I dont recycle aluminum but I should have no place to store it yes it makes a difference because in stead of making more they can melt down what has already been made the contamination to our environment would be less I think re teaching about recycling an where to turn them in would be good along with showing how the aluminum impacts our environment when its not recycled would work

- Q: What is the reflectivity of aluminum coils?

- When we talk about the reflectivity of aluminum coils, we are referring to their capacity to reflect light. Aluminum is renowned for its remarkable reflectivity, boasting a reflectivity percentage ranging from 80 to 90%. This outstanding feature makes it an excellent material for numerous applications that require reflective qualities, including the production of mirrors, solar panels, and lighting fixtures. The superior reflectivity of aluminum coils enables efficient light reflection, resulting in minimal energy wastage and optimal performance for these applications.

- Q: Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes. Aluminum is a non-magnetic material, meaning it does not have any magnetic properties. In order to use coils for magnetic purposes, materials with magnetic properties such as iron or steel are commonly used. These materials can generate and conduct magnetic fields, whereas aluminum cannot.

Send your message to us

Royal Brown Marble Grain Aluminum Coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords