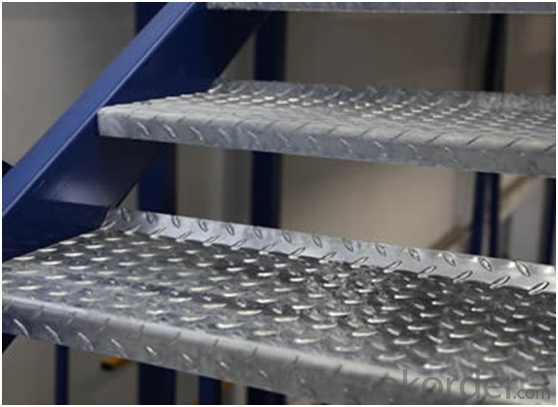

Aluminium Alloy Treadplate and Checker Plate for Floor, Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Tread Plate

l Production Introduction

1. Commodity: Aluminium Alloy Treadplate and Checker Plate for Floor, Step

2. Alloy No.: 1050 1060 1100 3003 3004 3104 3005 3105 5005 5052 5754 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators, buses,

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

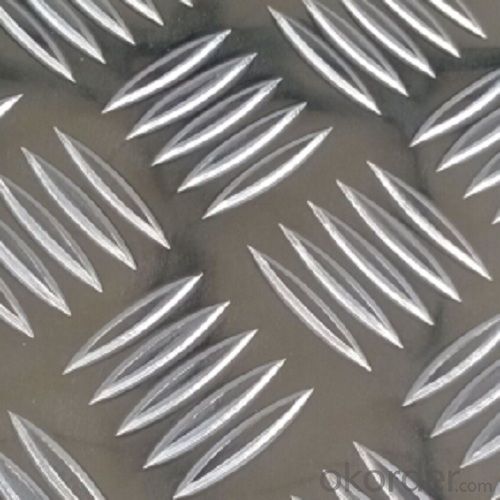

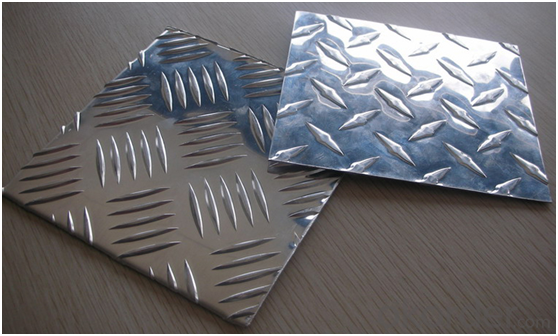

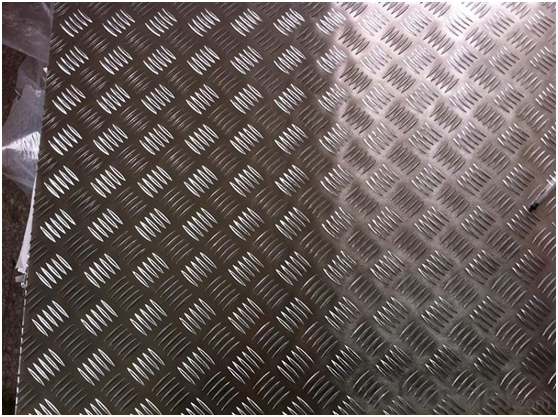

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium treadplate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Can aluminum sheet be used for aerospace structural components?

- Certainly, aerospace structural components can indeed utilize aluminum sheet. In the aerospace industry, aluminum is widely employed owing to its advantageous characteristics, including a high strength-to-weight ratio, resistance to corrosion, and excellent formability. By using aluminum sheet for these structural components, it becomes possible to construct aircraft that are lightweight, a crucial factor for optimizing fuel efficiency and performance. Moreover, aluminum is readily accessible and cost-effective, making it a favored option for aerospace applications. Nevertheless, it is worth mentioning that the selection of the aluminum sheet's specific grade and thickness will depend on the precise requirements and specifications of the aerospace structural component.

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available, including plain, embossed, perforated, and painted aluminum sheets.

- Q: What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: Aluminum shallow pattern boardThe shallow pattern board of aluminum alloy is one of the excellent building decoration materials. It is exquisite pattern, color appearance, has the common advantages of ordinary aluminum plate, the stiffness is increased by 20%, anti fouling, anti scratch, anti abrasion ability has been improved, especially the increase of three-dimensional pattern and beautiful color, make the building more brightly.Aluminium alloy decorative panels: aluminium and aluminium alloy corrugated platesAluminum and Aluminum Alloy corrugated plate is widely used in the world of decorative materials, it is mainly used for wall decoration, can also be used for roofing, surface chemical treatment can have a variety of colors, good decorative effect, but also has a strong reflection of the light, very durable, the service life of up to 20 years. And it has a variety of colors, both decorative effect, but also has a strong ability to reflect sunlight. It can resist fire, moisture and corrosion.

- Q: What are the different methods of surface coloring aluminum sheets?

- Aluminum sheets can be colored using various methods, each with its own strengths and limitations. Let's explore some of the commonly used techniques: 1. Anodizing: Anodizing is a favored method for coloring aluminum sheets. It entails creating a controlled oxide layer on the surface of the aluminum through an electrochemical process. This layer can be dyed in different colors, resulting in a resilient and long-lasting finish. Anodized aluminum is resistant to corrosion, UV rays, and scratches, making it an excellent choice for outdoor applications. 2. Powder coating: Powder coating is another popular technique for coloring aluminum sheets. It involves applying a dry powder coating to the sheet's surface, which is then cured in an oven. The powder melts and forms a protective layer that adheres to the aluminum. Powder coating offers a wide range of colors and finishes, and it provides exceptional durability, fade resistance, and scratch protection. 3. Painting: Painting is a traditional method for coloring aluminum sheets. It requires applying a liquid paint to the surface, which subsequently dries and forms a protective layer. Painting offers a vast array of color options and can achieve various finishes, such as matte, gloss, or metallic. However, painted aluminum sheets may require additional protective coatings to enhance durability and fade resistance. 4. Cladding: Cladding is a technique that involves applying a thin layer of colored material, such as stainless steel, copper, or composite panels, onto the aluminum sheet's surface. This method allows for a wide range of colors and finishes, while also providing extra protection. Cladding can be utilized to achieve a unique aesthetic or enhance the durability of the aluminum sheet. 5. Dye sublimation: Dye sublimation is a specialized method of coloring aluminum sheets, which employs heat and pressure to transfer designs or images onto the surface. This process enables high-resolution prints and vibrant colors, making it particularly suitable for decorative and signage applications. Each method of coloring aluminum sheets has its own advantages and considerations, such as durability, aesthetics, cost, and application requirements. It is crucial to thoroughly assess these factors when determining the most suitable method for a specific project.

- Q: What does 1060h/24 mean in aluminium alloy?

- In two the number of Arabia aluminum has no special meaning, is only used to identify the different alloys in the same group, said its second modifications.Four, H24 H said the work hardening of the state, and some do not have H but T said it is heat treatment.24 machining process control hardness and other properties, in addition to 24 and 12, 14, 16, 18, 22, 26, 34, 36 and so on, usually at the end of 4 is a semi hard state.1060O, 1060-H22, 1060-H24, 1060-H18 state is arranged from soft to hard.

- Q: What are the colors of iron sheet and aluminum sheet?

- white

- Q: What are aluminum sheets made of?

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Q: This question asks for a comparison of various types of aluminum sheet materials, highlighting their unique characteristics and differences.

- <p>Aluminum sheet materials vary based on alloy composition, thickness, and surface treatment. Common types include 1000 series (99% pure aluminum), 3000 series (alloys like 3003 and 3004), 5000 series (magnesium alloys), and 6000 series (magnesium-silicon alloys). Each series has distinct properties: 1000 series is soft and ductile, 3000 series offers moderate strength and good formability, 5000 series has high strength and corrosion resistance, and 6000 series is known for its strength and excellent weldability. Thickness and temper (hardness) also affect performance, with thinner sheets being more flexible and harder tempers offering greater strength. Surface treatments like anodizing or painting can enhance appearance and corrosion resistance.</p>

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- To ensure a strong and durable bond between the adhesive and the aluminum surface, various surface preparation methods are available. One commonly used method is mechanical abrasion, where the surface of the aluminum sheet is roughened using abrasive materials like sandpaper or wire brushes. This creates a textured surface that enhances adhesive adhesion. Chemical etching is another option, involving the treatment of the aluminum surface with a chemical solution to eliminate any oxide layer and establish a clean and reactive surface. Depending on the adhesive's specific requirements, acids or alkalis can be utilized for this purpose. For adhesives that necessitate a contaminant-free surface, solvent cleaning can be employed. This process involves the use of solvents like acetone or isopropyl alcohol to eradicate grease, oil, or dirt from the aluminum sheet's surface. In addition to these techniques, specialized methods like anodizing and chromate conversion coating can also be utilized. Anodizing entails the creation of a thick oxide layer on the aluminum surface through an electrolytic process, thereby improving bonding properties. On the other hand, chromate conversion coating involves treating the aluminum surface with a chemical solution containing chromates, resulting in the formation of a protective layer that enhances adhesion. Ultimately, the selection of a surface preparation method depends on the adhesive's specific requirements and the desired bond strength. It is crucial to carefully choose and follow the appropriate method to successfully bond aluminum sheet with adhesive.

- Q: Can aluminum sheets be used for architectural sunshades?

- Yes, aluminum sheets can be used for architectural sunshades. Aluminum is a lightweight and durable material that is commonly used in construction and architecture. It can be easily shaped and manipulated to create various designs and configurations for sunshades, providing protection from sunlight and enhancing the aesthetic appeal of buildings. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications and ensuring the longevity of sunshade structures.

Send your message to us

Aluminium Alloy Treadplate and Checker Plate for Floor, Step

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords