Finished Foil Industrial Aluminum Coil for Aluminium Anodizing Quality Curtain Wall/Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Anodizing Quality for Curtain Wall/Glass Wall Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Anodizing Quality for Curtain Wall/Glass Wall:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

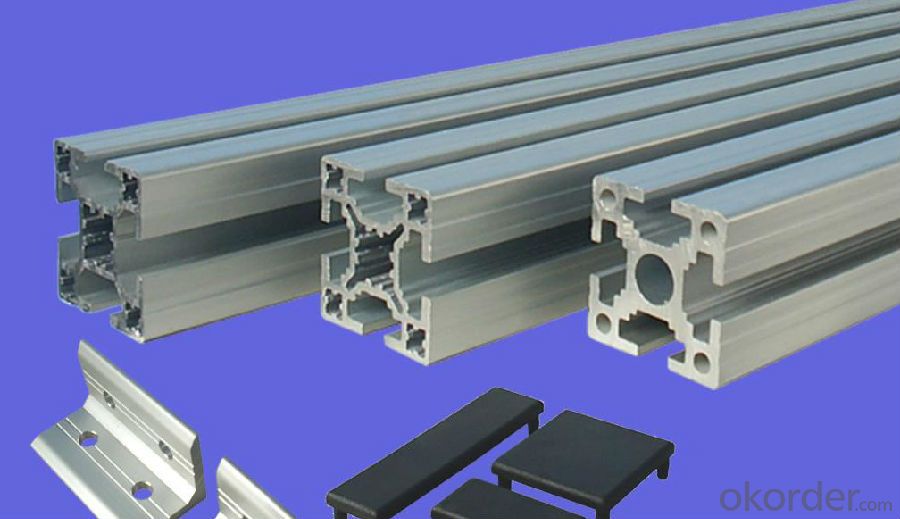

Images of the Aluminium Anodizing Quality for Curtain Wall/Glass Wall:

Aluminium Anodizing Quality for Curtain Wall/Glass Wall Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What are the potential applications of anodized aluminum coils?

- Anodized aluminum coils have a wide range of potential applications due to their unique characteristics. They are commonly used in architectural and construction projects for cladding, roofing, and facades, as their anodized coating provides excellent durability, corrosion resistance, and aesthetic appeal. Other potential applications include electronic casings, automotive trim, signage, cookware, and industrial components, where the anodized coating offers protection against wear, abrasion, and chemicals. Additionally, the ability to dye the anodized coating enables customization and allows for decorative uses in jewelry, artwork, and consumer goods.

- Q: How are aluminum coils used in the production of transportation vehicles?

- Aluminum coils are used in the production of transportation vehicles primarily for their lightweight and durable properties. These coils are typically used to manufacture various components, such as body panels, frames, and engine parts. The use of aluminum helps reduce the overall weight of the vehicle, enhancing fuel efficiency and performance. Additionally, aluminum's corrosion resistance makes it ideal for withstanding harsh weather conditions and extending the lifespan of the vehicle.

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: How do aluminum coils contribute to energy-efficient lighting installations?

- Aluminum coils play a significant role in enhancing the energy efficiency of lighting installations. Firstly, aluminum is a highly conductive material that efficiently transfers heat away from the lighting system. This prevents the accumulation of heat, which can diminish the performance and lifespan of the lighting fixtures. By dissipating heat effectively, aluminum coils help maintain optimal operating temperatures, ensuring the lights operate at their highest efficiency. Furthermore, aluminum coils are lightweight, making them easier to handle and install. This reduces the overall weight of the lighting fixtures, making them more convenient to mount and manipulate during installation. The reduced weight also translates into lower energy consumption during transportation and installation, ultimately contributing to energy efficiency in the long run. In addition, aluminum coils are highly durable and resistant to corrosion, which is crucial for lighting installations exposed to various environmental conditions. This durability minimizes the need for frequent replacements or repairs, reducing energy consumption associated with maintenance. Moreover, aluminum is a recyclable material, meaning that the coils can be easily reused or repurposed at the end of their life cycle. Recycling aluminum requires significantly less energy compared to producing new aluminum, resulting in a reduced carbon footprint and lower energy consumption overall. Overall, aluminum coils offer numerous benefits in terms of energy efficiency for lighting installations. Their efficient heat dissipation, lightweight nature, durability, and recyclability contribute to optimized performance, reduced energy consumption, and a more sustainable lighting solution.

- Q: What is the tensile strength of aluminum coils?

- The tensile strength of aluminum coils can vary depending on the specific grade and manufacturing process, but it typically ranges from 25,000 to 45,000 pounds per square inch (psi).

- Q: What are the different color coating options for aluminum coils?

- Customers have a variety of color coating options to choose from for their aluminum coils, depending on their specific needs and preferences. Some commonly used color coating options include: 1. Polyester (PE) Coating: This is a popular choice due to its excellent color retention, durability, and resistance to UV radiation, making it suitable for indoor and outdoor applications. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings offer superior weather and chemical resistance, as well as color stability. They are highly durable and can withstand harsh environmental conditions, making them suitable for architectural applications. 3. High-Durability Polyester (HDP) Coating: HDP coatings are specially formulated for enhanced durability and resistance to fading, chalking, and abrasion. They are commonly used in demanding applications where long-term color retention and performance are crucial. 4. Silicone Modified Polyester (SMP) Coating: SMP coatings provide good weather resistance, flexibility, and color stability. They are often used in industrial and commercial applications where a balance between performance and cost-effectiveness is required. 5. Polyurethane (PU) Coating: PU coatings offer excellent chemical resistance, flexibility, and adhesion properties. They are commonly used in applications requiring resistance to chemicals, solvents, and harsh weather conditions. In addition, each coating type offers various color options, giving customers a wide range of colors and finishes to choose from. Some manufacturers also offer custom color matching services to meet specific design requirements. It is important to consider factors such as the intended use, environmental conditions, durability requirements, and aesthetic preferences when selecting the appropriate color coating option for aluminum coils. Consulting with a trusted supplier or coating specialist can help determine the most suitable option for a specific application.

- Q: Are there any limitations to using aluminum coils?

- Using aluminum coils comes with several limitations. Firstly, their cost is higher compared to other materials like copper, which can be a constraint for those with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means they are less efficient at transferring heat, resulting in decreased performance in some applications. In addition, aluminum is more prone to corrosion and oxidation than other materials. This limitation is particularly relevant in highly corrosive environments, like coastal areas or industrial settings. Moreover, aluminum coils are generally unsuitable for high-pressure applications. They are more likely to experience leaks or failures under high pressure, which restricts their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are less malleable than copper coils, making them more challenging to handle during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, although aluminum coils have advantages like being lightweight and environmentally friendly, their limitations must be carefully considered based on the specific application and requirements.

- Q: How do aluminum coils contribute to fire safety?

- Aluminum coils contribute to fire safety by being non-combustible and having a high melting point. This means that in the event of a fire, aluminum coils will not burn or contribute to the spread of flames. Additionally, they are often used in fire-resistant building materials and electrical wiring due to their ability to dissipate heat efficiently, reducing the risk of fire hazards.

- Q: How are aluminum coils inspected for quality control?

- Aluminum coils are inspected for quality control through a combination of visual inspections and various non-destructive testing methods. These measures ensure that the coils meet the required specifications and are free from any defects or flaws. Visual inspections involve trained personnel carefully examining the coils for surface defects such as scratches, dents, or any irregularities in shape or size. The inspectors also check for any signs of contamination, oxidation, or discoloration. Any abnormalities detected during this visual inspection are noted and addressed accordingly. In addition to visual inspections, non-destructive testing techniques are employed to evaluate the internal quality of the aluminum coils. One commonly used method is ultrasonic testing, where high-frequency sound waves are transmitted through the coils. The reflected sound waves are analyzed to identify any internal defects like voids, cracks, or delaminations. This technique allows for a thorough assessment of the coil's integrity without causing any damage to the material. Another non-destructive testing method used for quality control is eddy current testing. This technique involves inducing electrical currents in the coils and measuring the resulting magnetic fields. Any variations in the magnetic fields can indicate flaws or defects in the aluminum, such as cracks or inclusions. Eddy current testing is particularly effective in detecting surface defects and discontinuities. Furthermore, measurements of important physical properties like thickness, width, and flatness are taken to ensure they meet the required standards. This is typically done using specialized instruments such as micrometers, calipers, or laser scanners. Overall, the inspection of aluminum coils for quality control involves a combination of visual inspections and non-destructive testing techniques to ensure that the coils are free from defects, meet the required specifications, and are of high quality.

Send your message to us

Finished Foil Industrial Aluminum Coil for Aluminium Anodizing Quality Curtain Wall/Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords