Aluminum Coil China - Direct from Aluminum Coil Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

aluminium coil

good quality

competitive price

short delivery time

long mutual beneficial business cooperation

Detailed informations

1.Alloy:AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011

2.Temper : H12, H14, H16, H18, H22, H24, H26, H32,HO, F

3. Thickness : 0.02mm – 10mm

4. Width : 10mm- 2000mm

5. Standard : ISO9001:2000, SGS , GB/T17748-1999, ASTM, EU standard .

6. Inner diameter : 150mm , 405mm ,500mm 505mm , 508mm

7. Coil weight : 1.5tons – 5.0 tons

8. Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

9. Shipment: By bulk vessel or By container

Applicating:

general using, Roofing, siding panels, shutters, warehouse and pre-fabricated houses, partitions, doors, home appliances, steel furniture,etc.

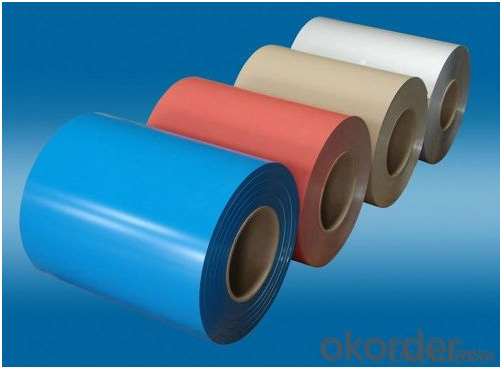

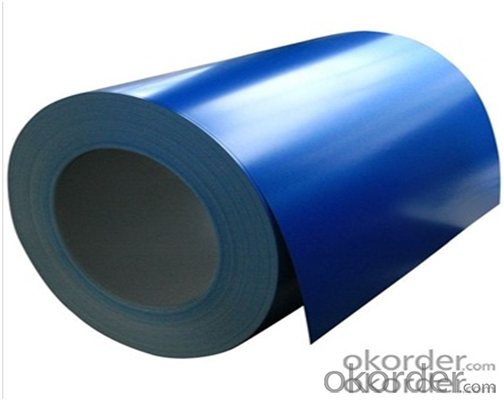

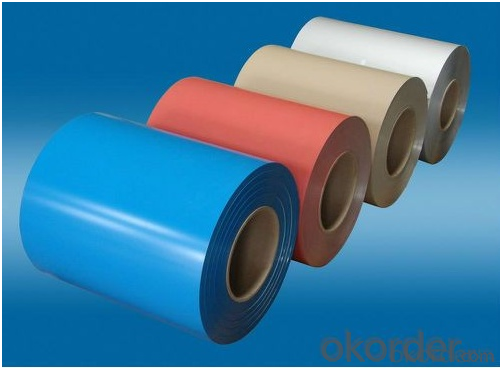

Colored coil is high in strength, good in rain and corrosion resistance,widely used in construction industry, such as modern courtyard design, large-sized industrial buildings, prefabricated thermal insulation sandwich board, etc. Along with the development of light industry, transportation and ship building, the application of colored sheet has been expanded form building materials to automobile manufacturing,watercraft interior decoration. Household electrical appliance, furniture, container and cooker, etc., and become a new material substituting to spray coating steel sheet.

Quality:

is a way of life for us and we live by quality in this industry. The quality of our

products and services are widely recognized and we have been maintaining

international quality standards. All the products that we suppliy pass through stringent

quality test before they finally arrive and that gives us a cutting edge over others,

managing in this sphere.

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

Pictures

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a high-quality aluminum coil, consider the following factors: purity level, which should be 99.5% or higher for most applications; surface finish, ensuring it's smooth and free from defects; thickness consistency, which should be uniform across the entire coil; mechanical properties, such as tensile strength and elongation, that meet industry standards; and adherence to specific alloy grades for particular applications. Additionally, check for certifications from recognized standards organizations and consider the supplier's reputation for quality and consistency.</p>

- Q: Can aluminum coils be used in the production of aluminum composite doors?

- Aluminum composite doors can indeed incorporate aluminum coils. These doors are crafted by sandwiching a core material between two aluminum sheets. The core material can consist of various substances, such as polyethylene or fire-resistant minerals. There are several benefits to using aluminum coils in the manufacturing of aluminum composite doors. Firstly, aluminum is a lightweight substance, rendering the doors easier to handle and install. Secondly, aluminum boasts exceptional resistance to corrosion, guaranteeing the doors' longevity and durability. Moreover, aluminum coils can be manipulated and molded with great ease, allowing for the creation of personalized designs and styles. The utilization of aluminum coils in the production of aluminum composite doors further provides flexibility in terms of color choices. Aluminum can be powder coated or painted in a myriad of hues, enabling a broad spectrum of options to cater to diverse architectural styles and individual preferences. In conclusion, aluminum coils are a fitting and widely employed material in the fabrication of aluminum composite doors due to their lightweight nature, resistance to corrosion, and customizable properties.

- Q: Can aluminum coils be used in automotive suspension systems?

- Automotive suspension systems can utilize aluminum coils. Aluminum, a lightweight and sturdy material, provides numerous advantages for suspension components. Its high strength-to-weight ratio allows it to handle heavy loads without burdening the vehicle with unnecessary weight. This can enhance fuel efficiency and overall performance. Furthermore, aluminum is resistant to corrosion, making it particularly valuable for automotive suspension systems exposed to harsh weather conditions and road debris. By incorporating aluminum coils, manufacturers can ensure that suspension components have a longer lifespan and require less maintenance. In addition, aluminum coils possess superior heat absorption and dissipation capabilities compared to materials like steel. This aids in preventing overheating and mitigating the risk of suspension failure, especially during intense driving conditions or off-road usage. However, it is important to note that the use of aluminum coils in automotive suspension systems may entail certain compromises. Although aluminum is lighter and more resistant to corrosion, it may not be as strong as steel. Therefore, manufacturers must meticulously design and engineer the suspension system to ensure it can withstand necessary loads and provide sufficient support and stability for the vehicle. In summary, aluminum coils can be effectively employed in automotive suspension systems, offering benefits such as lightweight construction, corrosion resistance, and efficient heat dissipation. Nevertheless, manufacturers must carefully consider the specific requirements and trade-offs associated with aluminum usage in suspension components to ensure optimal performance and safety.

- Q: This question is asking for a comparison of various types of aluminum coils, highlighting their unique characteristics and uses.

- <p>Aluminum coils are differentiated by their thickness, alloy composition, surface treatment, and temper. Common types include 1000 series coils with high purity, 3000 series known for formability, 5000 series for corrosion resistance, and 6000 series for strength. Thickness varies from thin gauges used in packaging to thick ones for construction. Surface treatments can include anodizing, painting, or lacquering for enhanced properties. Temper refers to the hardness and strength, with 'H' for hard and 'O' for soft tempers. Each type serves specific industries, such as automotive, aerospace, construction, and packaging.</p>

- Q: What are the acoustic properties of buildings using aluminum coils?

- The acoustic properties of buildings using aluminum coils can be influenced by various factors. Aluminum coils are commonly used in the construction industry for roofing, cladding, and insulation purposes. From an acoustic perspective, these properties can have both positive and negative impacts on the sound transmission within a building. One of the primary acoustic benefits of using aluminum coils is their ability to act as a reflective barrier for sound waves. When properly installed, aluminum coils can help prevent sound from penetrating through walls or ceilings, resulting in a reduction in external noise sources. This can be particularly beneficial in areas with high levels of noise pollution, such as urban environments or near busy roads. Additionally, aluminum coils can contribute to the overall sound insulation of a building. Due to their material properties, they can provide a certain level of soundproofing, especially when combined with other insulation materials. This can help maintain a comfortable and quiet indoor environment, allowing for improved concentration, productivity, and overall well-being of occupants. However, it is important to note that the acoustic properties of buildings using aluminum coils can also have limitations. Aluminum is a lightweight material compared to alternatives like concrete or brick, which means it may not provide as much mass to block sound transmission. Therefore, in situations where high sound insulation is required, additional measures such as double glazing, acoustic seals, or thicker wall constructions may be necessary. Furthermore, the use of aluminum coils can also affect the sound reverberation within a space. Due to their smooth and reflective surface, aluminum coils can potentially cause sound waves to bounce off, leading to increased echo and reverberation time. This can negatively impact speech intelligibility and acoustic comfort, especially in larger open-plan areas or rooms with high ceilings. Overall, while aluminum coils can offer certain acoustic advantages such as sound reflection and insulation, it is important to consider the specific requirements of each building project. Consulting with acoustic engineers or professionals can help ensure that the appropriate measures are taken to optimize the acoustic properties of buildings using aluminum coils, and to address any potential limitations.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: How do you clean and maintain aluminum coils?

- To clean and maintain aluminum coils, you can follow a few simple steps. First, gather the necessary materials, including a soft brush or vacuum cleaner, a mild detergent or coil cleaner, a water hose, and a spray bottle. Start by turning off the power supply to the unit and ensuring that it is safe to proceed. Next, remove any debris or loose dirt from the coils using a soft brush or a vacuum cleaner with a brush attachment. Be gentle to avoid damaging the fragile fins of the coils. Once the loose dirt is removed, mix a solution of mild detergent or coil cleaner with water in a spray bottle. Spray the solution onto the coils, ensuring that it covers the entire surface. Let it sit for a few minutes to allow the solution to penetrate the dirt and grime. After the solution has had time to work, use a soft brush or a soft cloth to gently scrub the coils. Be careful not to apply excessive pressure or use abrasive materials, as this could cause damage. Pay extra attention to any areas with stubborn dirt or buildup. Once you have thoroughly cleaned the coils, rinse them off with a water hose. Ensure that all the detergent or coil cleaner is completely washed away. Make sure to direct the water flow in the opposite direction of the air flow to avoid pushing debris further into the coils. After rinsing, allow the coils to dry completely before turning the power supply back on. This will prevent any potential electrical hazards. You can use a fan or leave the coils to air dry naturally. To maintain the cleanliness of the coils, it is recommended to clean them at least once a year or more frequently if the unit is exposed to heavy dirt or debris. Regularly inspecting the coils for dirt buildup and promptly cleaning them will help maintain the efficiency and extend the lifespan of the aluminum coils.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: I bought a house that is older with aluminum windows, and the last owner did not seem to clean them for quite some time. The aluminum frames are a silvery milky white color and my neighbors that have the same windows look like chrome. I have brushed these windows with scrub brushes and green scouring pads even aluminum wheel cleaner, now my frame is a clean milky grey color, it just isnt polished like my neighbor has it, his is like chrome. I have tried silver polishes and this doesn't remove the grey film either - i need something stronger. Can anyone help???

- try alot of pure white vinigar on them. It works wonders.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- Aluminum recycling is very cost-effective. Unlike most materials, metal recycling pollutes less than producing new product because most of the pollution is created by mining and smelting ore.

Send your message to us

Aluminum Coil China - Direct from Aluminum Coil Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords