Bleach Water Aluminum Coils with PVDF and PE Color Coating

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 200 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PVDF Aluminum Coil for ACP Description

PVDF coated aluminum coils are specially processed through the technics of roller coating and baking with precise paints from BECKER INDUSTRIAL COATINGS in Sweden and THE VALSPAR CORPORATION in USA. The main material of PVDF is polyvinylidene fluoride resin; the utmost negative characteristic of the Fl atom can form a very strength high powerful Fl-C bond. Moreover, with the special symmetry molecule structure, the products are of strong weather resistance performance, anti-ultraviolet performance, super long durability and anti-corrosion performance, which can maintain very bright and glossy color even serving for 20 years in outdoor environment. Attributing to the abrasion resistance and impact resistance and flexibility, our products are of excellent mechanical processing performance.

PVDF coated aluminum coils are the highest priority of choice to high class aluminum composite panels, and its composite products are widely used in airport, exhibition center, administration center, star hotel and other symbol building.

2.Main Features of the Aluminum PVDF Coated Coil:

• Light Weight

• High Flatness

• Protecting Environment

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

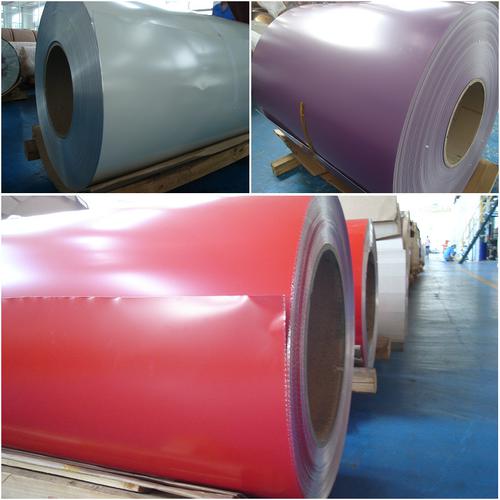

3.Aluminum PVDF Coated Coil Images:

4.Aluminum PVDF Coated Coil Specification:

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

PVDF Aluminum Coil for ACP

Features of PVDF Aluminum Coil:

1. Adopting precision rolling coating technology, our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced, there are various colors for your choice.

3. Using infrared heating technology to protect environment from pollution.

4. Our coated aluminum coil has four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF and special paints.

Specification of the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

5.FAQ

1. Color of Card

Our PVDF coated aluminum coil is made of fluorine carbon resin, pigment, ester solvent after high temperature roasting and baking. The paint of this PVDF coated aluminum coils are solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this PVDF coated aluminum coils are applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clear coating. It contains nanometer element, which can protect panel from pollution, because nanometer has self-cleaning effect, it is easy to get rid of dust and pollution by raining or water.

2. Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision.

3.How long can we receive the product after purchase?

15-20days for general specification and 35days for special specification after receiving the deposit.

- Q: Can aluminum coils be used in the production of aluminum wire?

- Yes, aluminum coils can be used in the production of aluminum wire. Aluminum wire is typically made by drawing or extruding aluminum rods or bars through a series of dies to reduce their diameter and increase their length. Aluminum coils, which are essentially continuous rolls of aluminum sheet or strip, can be used as a starting material in this process. The aluminum coils are first unwound and then fed into the wire production line to be further processed. They are typically annealed, cleaned, and then passed through a series of drawing dies to reduce their diameter and increase their length until the desired wire gauge is achieved. Therefore, aluminum coils can be an efficient and cost-effective starting material for the production of aluminum wire.

- Q: Are aluminum coils suitable for medical equipment applications?

- Yes, aluminum coils can be suitable for medical equipment applications. Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity properties. These factors make it an ideal material for various medical equipment applications, such as cooling systems, heat exchangers, and MRI coils. Additionally, aluminum coils can be easily formed and fabricated into complex shapes, allowing for customization based on the specific requirements of the medical equipment. However, it is important to note that the suitability of aluminum coils for medical equipment applications may also depend on other factors such as the specific medical device, regulatory requirements, and industry standards.

- Q: What are the different forming processes for aluminum coils?

- Some of the different forming processes for aluminum coils include rolling, coiling, slitting, and annealing.

- Q: What is the typical yield strength of aluminum coils?

- The typical yield strength of aluminum coils can vary depending on the specific alloy and temper, but it generally ranges from 15,000 to 35,000 pounds per square inch (psi).

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- Why not keep using the aluminum? It's 100 percent recyclable! That's even better than having something in a landfull bio-degrading over 10 years!

- Q: Never put oil in the water. Oil keeps the pasta from absorbing the sauce. Also add a little of the pasta water 3 Tbs. to the sauce. This helps sauce to adhere to pasta. The best remedy for pasta sticking. Use an aluminum stock pot. (tall pan). I don't know why but this works. I have using this stock pot for pasta for 40 years. I've tried stainless, non-stick, etc. they all stick. Except for the Aluminum.1 lb. of pasta, 4 qts. of water. 1Tbs. saltTurn burner to high,keep it therebring to boil then boil for 3 minutes, add 1 TBS salt, add pasta. Stir slowly 2 minutes, until the water boils. Cook tender enough for a fork to cut through but still a little firm

- Cooking in aluminum is not good! It leaches into the foods, you absorb it and it causes brain damage similar to parkinsons. I don't own any aluminum and I never will.

- Q: Can aluminum coils be used for industrial piping?

- Industrial piping can indeed utilize aluminum coils. Aluminum, being a versatile and lightweight material, presents numerous advantages for industrial piping purposes. Its exceptional resistance to corrosion makes it a suitable choice across various industries such as chemical, petrochemical, and food processing. Moreover, aluminum coils are effortlessly manageable and can be molded into diverse configurations and dimensions, providing flexibility when designing and installing piping systems. Furthermore, aluminum's commendable thermal conductivity proves advantageous for applications that necessitate heat transfer. Nevertheless, it is crucial to carefully contemplate the specific requirements of the industrial process and seek advice from professionals to guarantee that aluminum coils are appropriate for the intended application.

- Q: Are aluminum coils suitable for solar panel applications?

- Yes, aluminum coils are suitable for solar panel applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for solar panels. It provides excellent heat dissipation, ensuring optimal performance and efficiency of the solar panels. Additionally, aluminum is readily available and cost-effective, making it a popular option in the solar industry.

- Q: This question asks about the impact of aluminum coils on food quality, considering possible effects on taste, safety, and preservation.

- <p>Aluminum coils, when used in cooking or food packaging, can potentially affect the quality of food. If aluminum leaches into the food, it may alter the taste and could pose health risks due to aluminum's neurotoxic properties. However, modern food-grade aluminum coils are coated or anodized to prevent such leaching, ensuring food safety. They are also used in heat transfer for cooking, which can improve the efficiency and evenness of cooking, thus enhancing food quality. It's crucial to use high-quality, food-safe aluminum coils to avoid any negative impact on food quality and safety.</p>

- Q: How do aluminum coils perform in extreme temperatures?

- Aluminum coils are known for their excellent performance in extreme temperatures. They have a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making them highly resistant to heat. Additionally, aluminum has a low coefficient of thermal expansion, which means it can withstand rapid changes in temperature without warping or cracking. This makes aluminum coils a reliable choice for applications in both high and low-temperature environments.

Send your message to us

Bleach Water Aluminum Coils with PVDF and PE Color Coating

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 200 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords