Coated Aluminum Coil for Curtain Wall - Mill Finish Aluminum Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX

1.Structure of Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

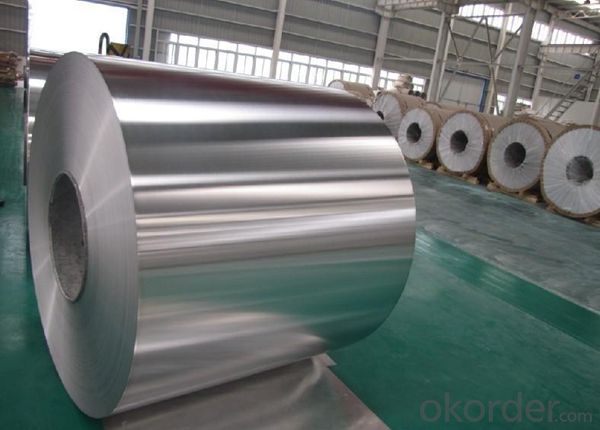

3. Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX Images

4.Specification of Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminum Coil for Curtain Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Is it possible to construct a bird feeder using an aluminum coil?

- <p>Yes, you can use an aluminum coil to make a bird feeder. Aluminum is lightweight, durable, and resistant to rust, making it a suitable material for outdoor use. To create a bird feeder, you can form the coil into a hanger or support structure, then attach a feeding platform or container where birds can access the food. Ensure the structure is stable and safe for birds to perch and feed. Remember to use appropriate tools and safety measures when working with aluminum, and consider painting or coating the coil to enhance its appearance and protect it from the elements.</p>

- Q: Are aluminum coils suitable for lightweight panel applications?

- Yes, aluminum coils are suitable for lightweight panel applications due to their inherent lightweight nature and high strength-to-weight ratio. Additionally, aluminum coils offer excellent corrosion resistance, making them a reliable choice for various lightweight panel applications.

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: What are the potential health hazards associated with the use of aluminum coils?

- <p>There are concerns about the health risks associated with using aluminum coils, particularly in cooking. Aluminum can leach into food when heated, and excessive intake may lead to cognitive impairment and neurological issues. However, the risk is generally considered low with normal usage. It's important to follow proper cooking practices and use utensils that are not reactive with aluminum to minimize exposure. For those with concerns, alternatives like stainless steel or cast iron can be used to reduce potential health risks.</p>

- Q: How are aluminum coils used in the production of cans and containers?

- Aluminum coils are of utmost importance in the manufacturing of cans and containers. Typically, these coils are created by continuously casting molten aluminum into thin sheets. Once cooled and solidified, the sheets are rolled into coils, which are then utilized in diverse manufacturing procedures. The initial step in utilizing aluminum coils for cans and containers involves the process of blanking. During this stage, a blanking press cuts the coil into individual circular blanks, which will eventually form the bottom and lid of the can. These blanks are meticulously cut to the required size and shape, guaranteeing precision and uniformity. Following that, the blanks are transported to a cupping press, where they are situated between a set of dies. High pressure is applied by the press, causing the blank to adopt the shape of a cup. This cup will eventually serve as the body of the can or container. The cup is then transferred to a redraw press, where it undergoes a series of operations aimed at enhancing its shape and dimensions. This process aids in achieving the desired thickness and height of the can or container. Moreover, the redraw press ensures that the cup maintains its structural integrity and can endure the challenges of storage and transportation. Once the cup has been redrawn, it is subjected to a trimming procedure to eliminate any excess material and achieve the final shape. This step guarantees that the can or container possesses a clean and smooth edge, ready for further processing. Subsequently, the cups are conveyed to a base-coating station. At this station, a thin layer of protective coating is applied to both the interior and exterior surfaces of the cups. This coating helps prevent corrosion and ensures that the contents of the can or container remain fresh and uncontaminated. Lastly, the coated cups pass through a necking press, where the upper section of the cup is shaped into a narrower neck. This neck is essential for attaching the lid or cap to the can or container, providing a secure seal. To sum up, aluminum coils play an essential role in the production of cans and containers. They are transformed into blanks, cups, and ultimately into the final product through a variety of manufacturing processes. These coils guarantee the durability, functionality, and integrity of cans and containers, making them suitable for a wide range of applications in industries such as food and beverages, pharmaceuticals, and cosmetics.

- Q: Are aluminum coils suitable for HVAC ductwork?

- Yes, aluminum coils are suitable for HVAC ductwork. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an ideal choice for HVAC ductwork. It offers excellent heat transfer properties and is commonly used in both residential and commercial HVAC systems.

- Q: So i like eating frozen foods like wings or bagel bites and i cook them in my toaster oven with aluminum foil under them on top of the tray. I heard using aluminum is bad for you and can get you diseases or illnesses. Is this true and should i stop using aluminum foil? i eat these frozen foods maybe 3-4 times a week

- over time excessive use leeches into the system and aluminium is a toxic metal that the blood- brain can not be protect against, and causes all sorts of permanent neurological damage, alzheimers, senility, parkinsons, MS, lots of things are linked to heavy metal toxicity, proven of course. Why don't you save your brain AND save money and buy yourself a tray that fits in the toaster oven so it can be reused. Obviously your brain health should be more important than money, but if you need more reason to stop using aluminum, think about the money you are throwing away several times a week that can be saved. Of course you'd save even more money if you stopped buying expensive pre-packaged frozen foods :D but I think the health of the brain has way more value than what's in your wallet in the long run.

- Q: What are the different coil packaging options for aluminum coils?

- The different coil packaging options for aluminum coils include wooden crates, steel frames, cardboard boxes, plastic wrapping, and pallets. These packaging options are chosen based on factors such as the size and weight of the coils, transportation requirements, and protection needed during storage or shipment.

- Q: What are the methods to prevent rust formation on aluminum coils during storage and transportation?

- <p>To prevent rust on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Store them in a cool, dry place away from moisture and corrosive substances. Use protective wrappings or coatings to shield the coils from the environment. Maintain proper ventilation to reduce humidity. Avoid stacking the coils directly on the ground; use pallets or racks to keep them off damp surfaces. Regularly inspect the coils for signs of moisture or damage and address any issues promptly.</p>

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

Coated Aluminum Coil for Curtain Wall - Mill Finish Aluminum Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords