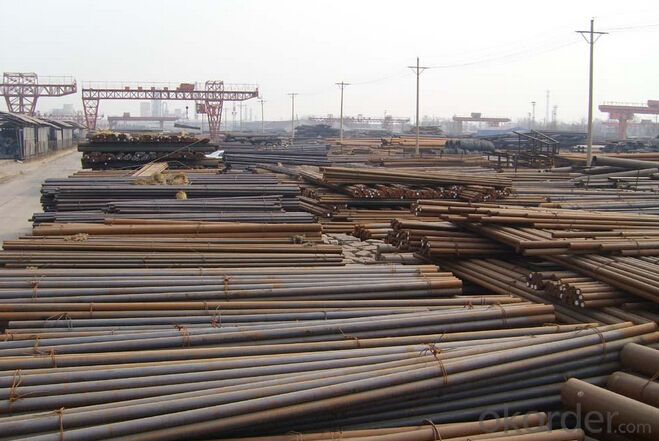

Alloy Steel 35CrMo Special Steel Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Chemical Composition(%)

| C | Si | Mn | Cr | Mo | Ni | P | S |

| 0.32-0.40 | 0.20-0.40 | 0.40-0.70 | 0.80-1.10 | 0.15-0.25 | ≤0.30 | ≤0.035 | ≤0.035 |

Standard

| GB | AISI | DIN | JIS | BS |

| 35CrMo | 4137 | 34CrMo4 | SCM432 | 708A37 |

Available Size

| Rolled round bar | φ20-120mm × L |

| Forged round bar | φ130-195mm × L |

Characterstics

| The steel with high strength and toughness, hardenability is better also | |||||||

| After conditioning treatment quenching deformation of small | |||||||

| high fatigue limit and repeated impact resistance |

Applications: The steel is suitable for manufacturing requires a certain strength and toughness of large and medium-sized plastic mold

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different case hardening grades of special steel?

- Special steel offers a variety of case hardening grades, each with its own distinct properties and uses. Some of the commonly employed grades are: 1. 8620: This grade is commonly utilized for high-stress applications like gears and shafts. Its remarkable toughness and resistance to wear make it ideal for parts requiring both durability and strength. 2. 9310: Aerospace applications often rely on this grade due to its high strength and resistance to fatigue. It is frequently employed for gears, bearings, and components demanding exceptional toughness and load-carrying capacity. 3. 4340: Known for its hardenability and high strength, this grade is suitable for parts necessitating great tensile strength and impact resistance, such as crankshafts, connecting rods, and gears. 4. 20MnCr5: This grade finds frequent use in the production of gears, camshafts, and components requiring high surface hardness and resistance to wear. It boasts excellent case-hardening properties and good core strength. 5. EN36C (also referred to as 655M13): This grade is commonly employed for axles, shafts, and crankshafts requiring high tensile strength. Its good hardenability and exceptional toughness make it suitable for heavy-duty applications. To ensure the right grade is chosen for a specific project, it is crucial to consider the application requirements, including desired hardness, strength, and wear resistance. Seeking advice from a metallurgist or materials science expert can aid in selecting the appropriate case hardening grade.

- Q: How does special steel contribute to the automotive exhaust system industry?

- Special steel contributes to the automotive exhaust system industry by offering enhanced durability, corrosion resistance, and heat resistance. It allows for the production of exhaust components that can withstand high temperatures and harsh conditions, resulting in improved performance and longevity of the system. Additionally, special steel enables the design of lightweight exhaust systems, which contribute to fuel efficiency and reduce emissions.

- Q: How is special steel used in the packaging supply chain?

- Special steel is used in the packaging supply chain for various purposes such as manufacturing machinery, tools, and equipment needed for packaging processes. It is used to create durable and reliable components like blades, cutters, and molds, ensuring precise and efficient packaging operations. Additionally, special steel can be utilized for constructing robust packaging materials like containers, pallets, and racks, providing strength and stability during transportation and storage.

- Q: What are the factors that affect the wear resistance of special steel?

- There are several factors that affect the wear resistance of special steel. Some of the key factors include the composition of the steel, particularly the presence of alloying elements such as chromium, tungsten, and vanadium, as these elements can enhance the hardness and toughness of the steel. The microstructure of the steel also plays a significant role, with a fine-grained structure and a homogeneous distribution of carbides generally resulting in improved wear resistance. Additionally, the heat treatment process used to harden the steel can greatly influence its wear resistance, as it affects the formation and distribution of various microstructural features. Surface finish and lubrication conditions can also impact the wear resistance of special steel, as a smooth surface and proper lubrication can reduce friction and wear. Finally, the operating conditions, such as load, speed, and temperature, can significantly affect the wear resistance of special steel, as excessive loads or high temperatures can lead to increased wear and deterioration of the steel's performance.

- Q: What are the thermal properties of special steel?

- Special steel, also known as tool steel or alloy steel, possesses excellent thermal properties. It has a high melting point, allowing it to withstand extreme temperatures without losing its structural integrity. Furthermore, special steel exhibits good heat resistance, ensuring it retains its strength and hardness even when exposed to high thermal loads. Additionally, its thermal conductivity is relatively low, making it suitable for applications where heat transfer needs to be controlled or minimized. Overall, the thermal properties of special steel make it a reliable material for various industrial and engineering applications that involve high temperatures and thermal stresses.

- Q: How is special steel used in the manufacturing of consumer goods?

- Special steel is used in the manufacturing of consumer goods due to its exceptional properties such as high strength, durability, and corrosion resistance. It is utilized in various products like kitchen appliances, tools, automotive parts, and electronics, enhancing their performance and increasing their lifespan.

- Q: What are the main advantages of using special steel in the food processing industry?

- The main advantages of using special steel in the food processing industry are its high resistance to corrosion, durability, and hygiene. Special steel is specifically designed to withstand harsh environments, such as exposure to acidic or alkaline substances, which are common in food processing. It does not rust or react with food, ensuring the quality and safety of the final product. Additionally, special steel is easy to clean and maintain, making it an ideal choice for food processing equipment.

- Q: What are the safety considerations when handling special steel products?

- When handling special steel products, some important safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against cuts, burns, and impact injuries. It is also crucial to ensure proper lifting techniques are employed to prevent strains or back injuries. Additionally, storing the steel products in a secure and organized manner can help prevent accidents and injuries. Regular inspections of the equipment and tools used for handling the steel products should be carried out to identify any potential hazards or defects. Lastly, proper training and awareness of the specific safety protocols and procedures related to handling special steel products are essential to minimize risks and maintain a safe working environment.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in the beverage industry due to its corrosion resistance, hygiene properties, and durability. It is often utilized for the production of tanks, containers, piping, and other equipment involved in the processing, storage, and transportation of beverages.

- Q: How does special steel contribute to the chemical processing aftermarket industry?

- Special steel plays a crucial role in the chemical processing aftermarket industry by offering exceptional resistance to corrosion, high temperatures, and pressure. Its unique properties enable the production of high-quality and durable equipment such as valves, pumps, pipes, and heat exchangers. This ensures the safe and efficient handling of corrosive chemicals, thereby reducing maintenance costs, preventing leaks, and minimizing production downtime. Overall, special steel enhances the reliability, longevity, and performance of chemical processing equipment, making it an indispensable component of the aftermarket industry.

Send your message to us

Alloy Steel 35CrMo Special Steel Carbon Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords