Aircraft Aluminum Extrusion Profiles - Alloy 6060 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

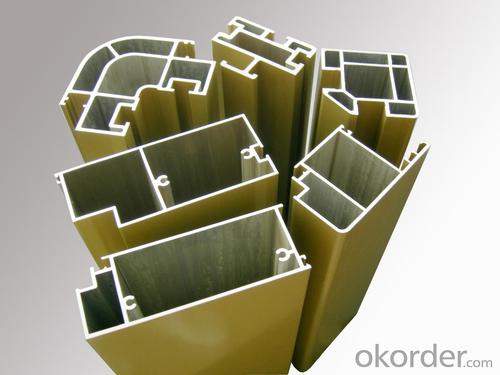

Product Name | Alloy 6060 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: How do you prevent warping or distortion of aluminum profiles during fabrication?

- In order to prevent warping or distortion of aluminum profiles during fabrication, there are several key measures that can be implemented: 1. Storage in a controlled environment is crucial prior to fabrication. It is essential to store the aluminum profiles in an environment with stable temperature and humidity levels. This will help minimize any potential changes in the shape or dimensions of the metal. 2. Proper handling techniques must be employed to avoid bending or twisting the aluminum profiles. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring even support during transportation. 3. During the fabrication process, it is important to utilize suitable machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Utilizing cooling techniques such as lubricants or coolants can disperse heat and prevent distortion. 4. Controlled welding is crucial when working with aluminum profiles. Maintaining proper control over the welding process is essential. Employing appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing methods should be employed during fabrication to ensure that the aluminum profiles are held in the correct position throughout the process. This prevents unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving processes can be implemented after fabrication to minimize residual stresses within the aluminum profiles. This will prevent distortion or warping that may occur during subsequent handling or usage. 7. Regular inspection and measurement of the aluminum profiles during fabrication is necessary to identify any deviations from the desired specifications. This enables prompt corrective actions to be taken, reducing the risk of warping or distortion. By implementing these steps, manufacturers can significantly decrease the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: What are the fire safety regulations for aluminum profiles?

- The fire safety regulations for aluminum profiles vary depending on the specific application and building codes in each jurisdiction. However, in general, aluminum profiles used in construction must meet certain fire resistance standards to ensure safety. This may include factors such as the thickness and composition of the aluminum, the use of fire-resistant coatings or insulation, and compliance with international fire safety standards like ASTM E119 or EN 13501. It is important to consult local building codes and regulations to determine the specific fire safety requirements for aluminum profiles in a particular area.

- Q: in addition to the groove width is not the same as other well differentiated? Is there any difference in wall thickness?

- There must be a difference. There is a distinction between rice weight and wall thickness. For example, Jing Teng Aluminum CompanyJT-8-5050W meters weight is 3.25KG,,JT-10-5050 meters weight is 2.95KG. Specific parameters, you can go to consult the next business

- Q: This question asks whether aluminum profiles can be utilized for creating interior partitions and seeks reasons for their suitability.

- <p>Yes, aluminum profiles can be used for interior partitions. They are favored for several reasons: they are lightweight yet strong, offering durability and stability. Aluminum profiles are also resistant to corrosion, which makes them suitable for various environments. Their ease of installation and low maintenance requirements make them cost-effective. Additionally, they can be easily customized to fit various design needs, and their recyclability makes them an environmentally friendly choice.</p>

- Q: What are the dimensions of standard aluminum profiles?

- The dimensions of standard aluminum profiles can vary depending on the specific profile and its intended use. However, common dimensions for standard aluminum profiles typically range from a few millimeters to several inches in width and height, with lengths varying based on the manufacturer's specifications.

- Q: When will the aluminum mold be padded?

- The plane will die pad is a small pad on the inside of the die sleeve, and a large pad size is the size of the inner diameter of the sliding seat, there are generally several square and circular pad, some special structure material need professional pad, such as an open slot, the structure is not very stable, when die under high pressure are squashed requires a special pad.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

- Q: Are aluminum profiles recyclable?

- Yes, aluminum profiles are recyclable. Aluminum is one of the most sustainable and widely recycled materials in the world. It can be recycled repeatedly without losing its quality, making it an environmentally friendly choice for various applications, including profiles.

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- To ensure proper electrical grounding with aluminum profiles, there are a few key steps that need to be followed. Firstly, it is important to ensure that all aluminum profiles are clean and free from any dirt, dust, or oxidation. This can be achieved by using a suitable cleaning agent or solvent to remove any contaminants that may hinder the grounding process. Next, proper electrical grounding can be achieved by using conductive hardware such as grounding clips or brackets specifically designed for aluminum profiles. These hardware components should be securely attached to the aluminum profiles, ensuring a reliable electrical connection. Additionally, it is crucial to establish a solid electrical connection between the aluminum profiles and the grounding system. This can be achieved by using copper or aluminum grounding conductors that are properly sized and securely connected to both the aluminum profiles and the grounding system. Furthermore, it is important to regularly inspect the grounding system to ensure its effectiveness. This can involve checking for any loose connections, signs of corrosion, or damage to the grounding conductors. Any issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is recommended to consult with a qualified electrician or engineer who specializes in electrical grounding when working with aluminum profiles. They can provide specific guidance and ensure compliance with relevant electrical codes and standards to ensure proper and safe electrical grounding.

Send your message to us

Aircraft Aluminum Extrusion Profiles - Alloy 6060 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords