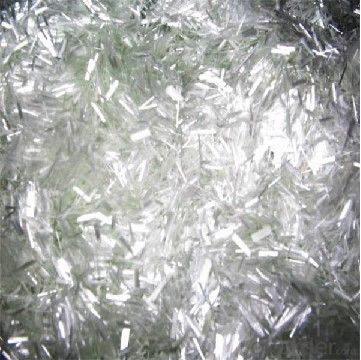

Alkali Resistant GRC Chopped strands for wall plastering materials

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Alkali Resistant GRC Chopped strands for wall plastering materials:

1) length:3.0mm,4.5mm,6.0mm,9.0mm,12mm,15mm

2) Good strand integrity

3) Low static

4) Good flowability

Features of Alkali Resistant GRC Chopped strands for wall plastering materials:

--Good strand integrity, low static and good flowability;

--Fast and uniform distribution in resins, good processing properties and good mechanical properties of the end products;

--Good bonding with resins. No fiber sticking out at the surface of the end products and aesthetic appearance.

Application of Alkali Resistant GRC Chopped strands for wall plastering materials:

It is mainly used in injection and compression molding processes and its typical end-use applications include automotive industry, home appliances, valves, pump housings, chemical corrosion resistance and sports apparatus.

Packaging of Alkali Resistant GRC Chopped strands for wall plastering materials:

The product can be packed in bulk bags, cardboard boxes or composite plastic woven bags;

Bulk bags can hold 500kg~1000kg each;

Cardboard boxes and composite plastic woven bags can hold 15kg~25kg each.

Storage of Alkali Resistant GRC Chopped strands for wall plastering materials:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15-35,35%-65% respectively.

- Q: what is r.h cement & what is the grade of it?

- For Rapid Hardening Cement ,grading is similar to O.P. cement(ordinary Portland cement) is M15,M20 is same. only initial final setting time is less.Strength of 28 days is considered for testing /Mix Designing.

- Q: Our pool liner ripped!! our pool is custom 11ft deep. we drained the pool we are removing the water from behind the liner. We are trying desperatly to make this liner last one more summer! Of course it ripped down at the 11 ft area. but the rip only runs along the top edge of the lip that snaps into the metal ring around the pool. I came up with the idea of using rubber cement to cement the ripped liner to the steel wall. Is this possible?? we just can't shell out 3,700.00 for a liner right now and its HOT the kids are driving us insane to try something ANYTHING does anyone have anybetter ideas?? we are open to any ideas! thanks

- the name rubber cement should give you a clue.

- Q: Is jypee cement best for house?

- in my opinion jypee cement is best for house because among of the other cement are not good but jypee cement is good.

- Q: Price of laying cement?

- Cement is pretty expensive when you add all the materials and labor. Depending on what you are looking at doing. Sidewalk can run you $250-$2000 depending on linear feet. A Driveway will probably be $5000+ depending on size. That gives you an idea...

- Q: I really need to have the maximum amount of information between these two main types of cement.Also, please give some examples of non - hydraulic and hydraulic cement.Thank you!

- Hydraulic cements are materials that set and harden after being combined with water, as a result of chemical reactions with the mixing water, and that, after hardening, retain strength and stability even under water. The key requirement for this strength and stability is that the hydrates formed on immediate reaction with water be essentially insoluble in water. Most construction cements today are hydraulic, and most of these are based on Portland cement, which is made primarily from limestone, certain clay minerals, and gypsum in a high temperature process that drives off carbon dioxide and chemically combines the primary ingredients into new compounds. Non-hydraulic cements include such materials as (non-hydraulic) lime and gypsum plasters, which must be kept dry in order to gain strength, and oxychloride cements, which have liquid components. Lime mortars, for example, set only by drying out, and gain strength only very slowly by absorption of carbon dioxide from the atmosphere to re-form calcium carbonate through carbonization.

- Q: What is the best thing to write in wet cement?

- This cement is now dry. or There is a dead body under here LOL Cheers from Australia

- Q: what's the difference between cement and mortor mix?

- Morter is for brick and stone. Cement is for paving and reinforcement.

- Q: What actually happens to make it set

- Wait a really long time

- Q: I live in a bright purple cement rendered home and want to paint it dark grey, but am unsure what paint to use or if I have to do any preparation to it before painting itPlease helpBrands available in Australia will helpThanks

- First, try using a power washer in the 2000 PSI range to take off the old paint. If it comes off (or most of it, anyway), let the cement dry for a couple days and then use a concrete primer before applying a color coat specifically made for concrete. The primer is especially acidic, so it really soaks into the cement (and it doesn't go very far, because so much soaks into the concrete). The concrete color coat is then designed to hold onto the primer and provide a solid moisture barrier. If the old color won't come off, don't worry. Just clean it up as best you can before applying the primer and paint. And, use top name brand paints (like Dunn-Edwards or Sherman Williams). The more expensive products will cover better and may actually be cheaper in the long run (less coats and time to paint).

- Q: strength and longevity

- Concrete is the finished product that results from mixing cement, sand or gravel and water. In other words, the difference is that cement is one component of concrete. Put another way - What is the difference between bread and flour?

1. Manufacturer Overview

| Location | Hubei,China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Southern Europe 10% Northern Europe 10% Central America 10% Western Europe 10% Eastern Asia 10% Mid East 30% Africa 20% |

| Company Certifications | N/A |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai PORT |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | 示范:High;Average |

Send your message to us

Alkali Resistant GRC Chopped strands for wall plastering materials

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15.6MTS

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords