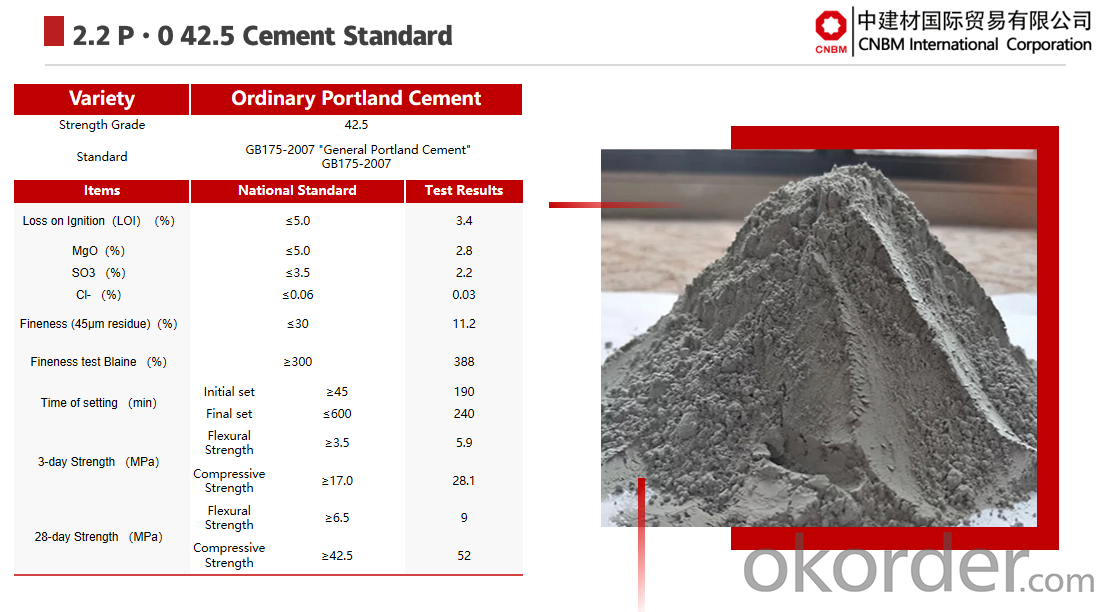

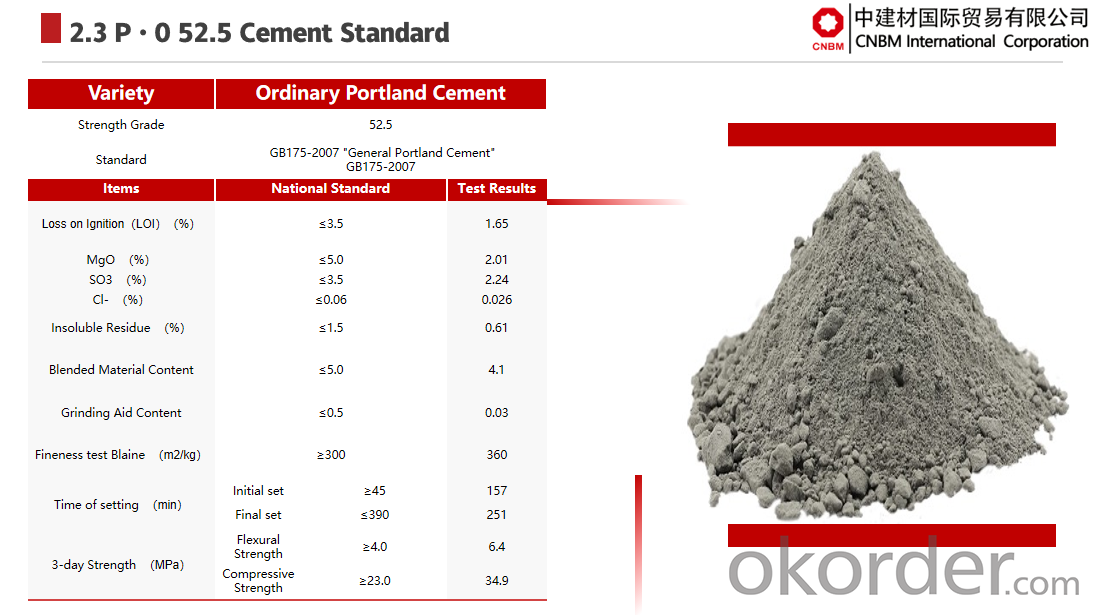

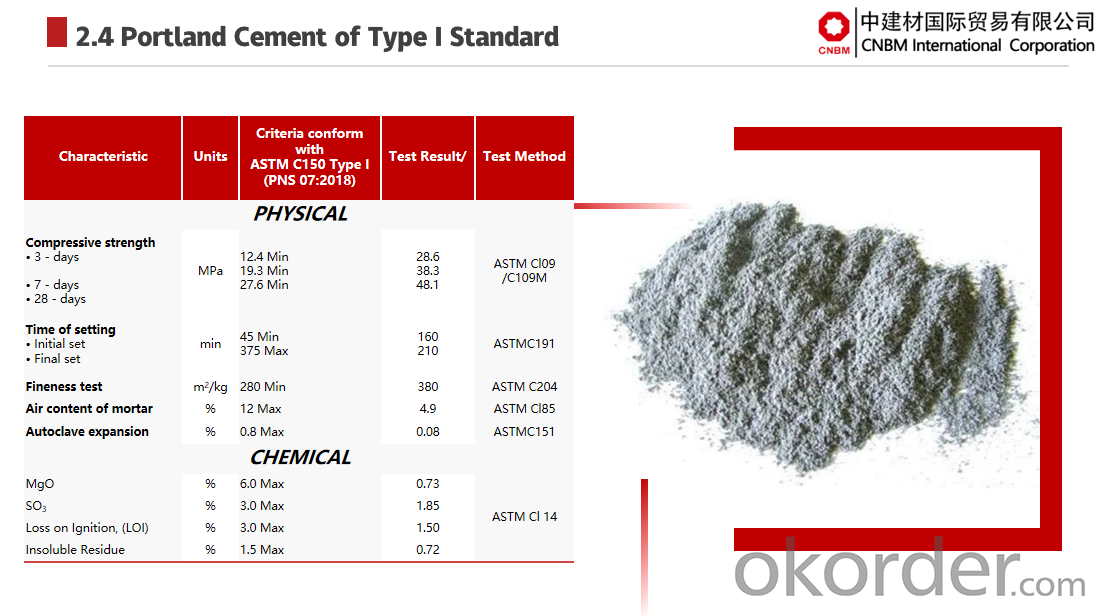

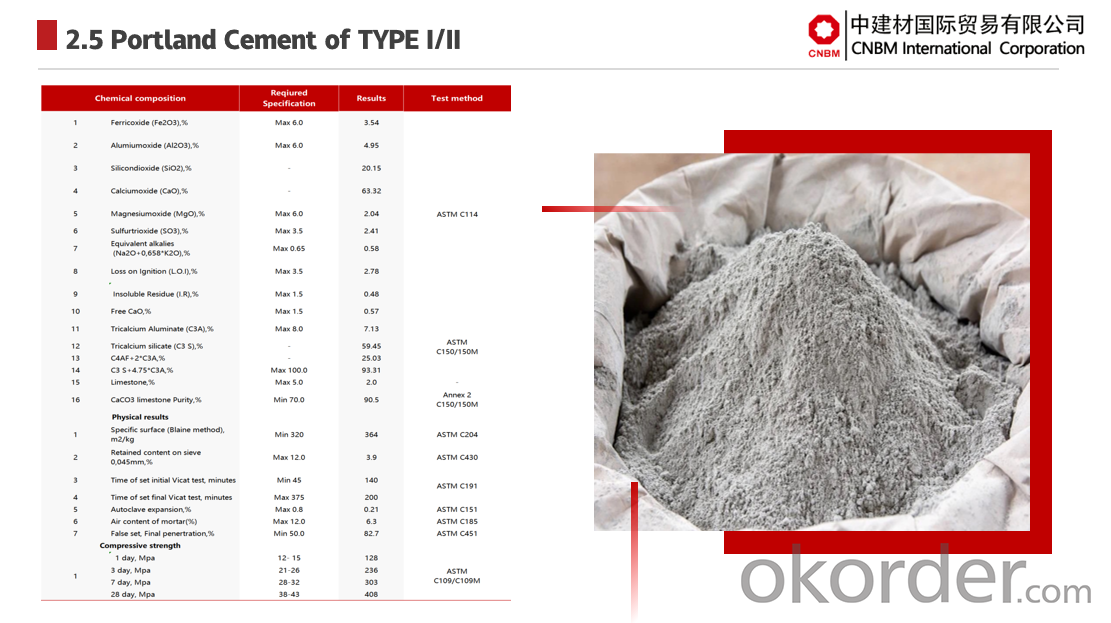

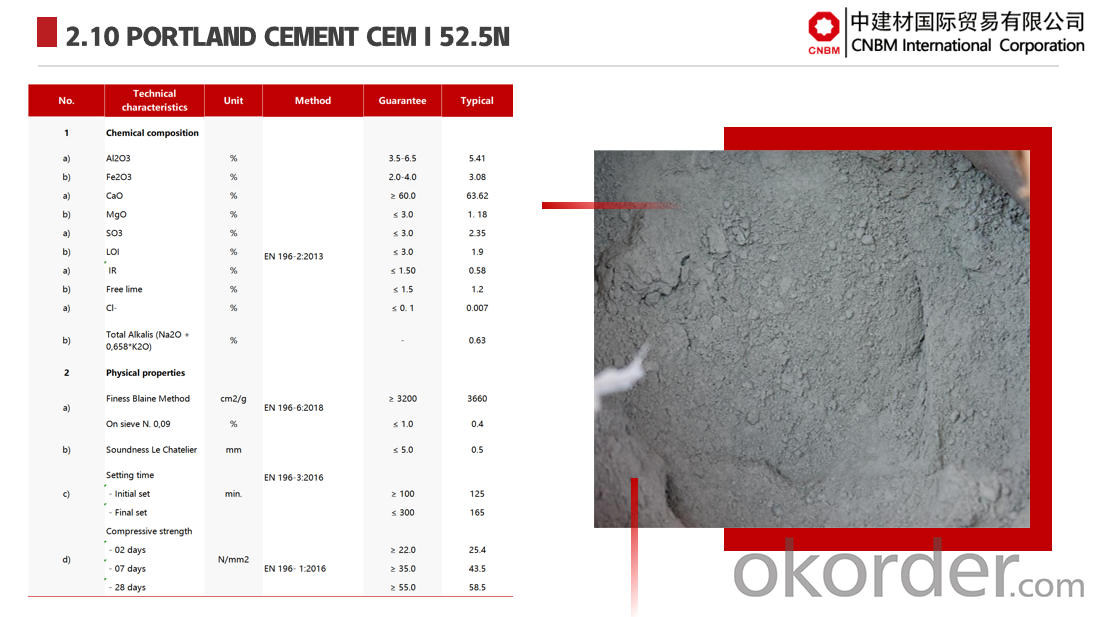

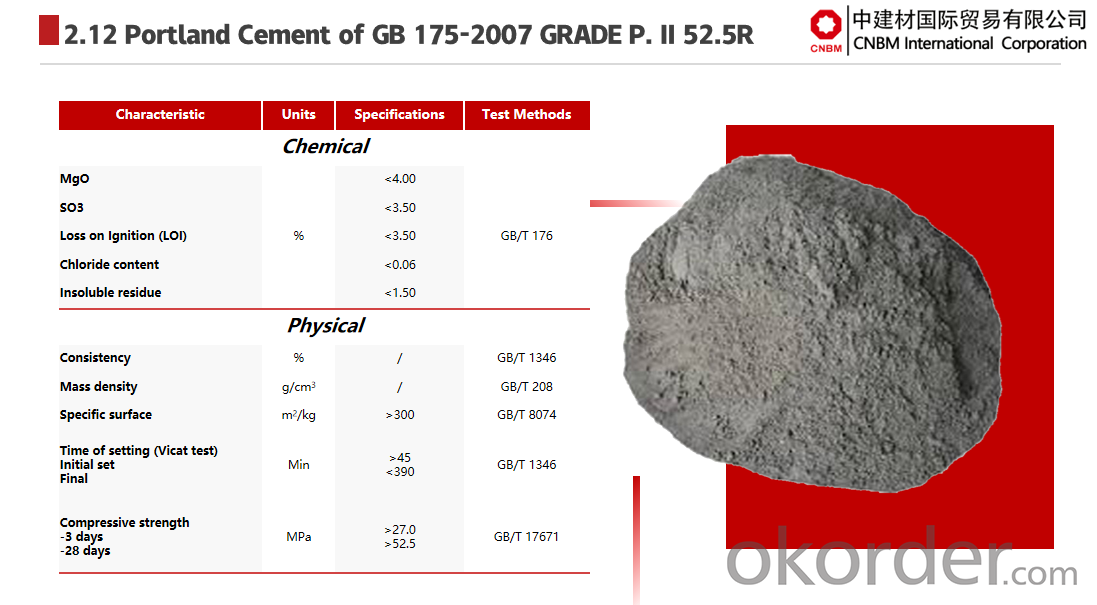

Highest quality for Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: What color is the cement they use to put a permanent crown on. When I was flossing the other day this hard white stuff came out from between my teeth where the crown is. Could that be cement, should I be worried? That tooth had a root canal and a crown and the crown is sensitive when I eat hard foods on it.

- It is definately considered early, I have a crown as well and my cement is blue, the white that the floss got out was most likely plaque or something along those lines. A tenderness is to be expected this early on

- Q: and it was lumpy can i still use it or will the lumps interfer with the leveling process, ( and how liquidy should i make it) i experimented with a little amount and it just didn't look right so i threw it out.. it's the firt time i'm using a self leveling product

- You want to mix the stuff so that it is like pancake batter. No lumps. The lumps are clumps of still dry concrete. Self leveling works like water.-which is level- So your surface that you want to have level needs a fence all around the perimeter say 3/8 x 2 wideplywood strips in a continuous border......then in the lower centre area (in many cases, the floors of houses, the heating wires get laid - - and then the leveling cement is poured onto the floor(it is runny like batter) and covers the wires and is stopped at the level of just under 3/8. Then it is left alone for a day or three. Then floor tile are dry laid ontop of the level floor....then glued down.

- Q: I was washing paint brushes in a bucket with water the bucket turned to mostley paint and then the bucket fell on my pation floor which is cement now it wont come off!!!!!!

- Why not just GO FOR IT and paint the rest of the floor?

- Q: My contractor charged me $450 for cement for laying out 600 sq ft tile on the floor. He told me he used 27 bags. This is in addition to grout. Cost seems very high. How many bags is typically needed?Thanks a lot

- Even if your floor is only 600 sq. ft but if its uneven then chances are he really consumed that much of cement bags. If your contract states, installation only then you will have to pay the contractor for the additional materials he used which was needed to complete the job.

- Q: what would happen if someone where you flush cement down the toilet? And should I do it?

- You would accidentally the whole thing. So don't do it.

- Q: Was the gulf oil leak sealed with cement as stated, or was it concrete?

- In the oil industry it is known as cement. Granted, there are non-cement constituents, but there is no aggregate as the concrete that we're most familiar with has. The cement has to flow through small gaps and can't have rock chunks in it. The cement used in the oilfield also has a number of other additives to control such things as setting time and flow characteristics (called rheology).

- Q: So I am doing a little project outside. I need to connect a pvc pipe to a rubber hose. water will be flowing between these two. I am going to use some sort of sealent along with a clamp thingy but wondering what type of sealent should i use. Is there a particular one should i use?

- you can use sealant if you want, but a hose clamp will work fine by itself. i've done this many times and the connection doesn't come apart or leak.

- Q: What is it that the dentist use to get rid of braces? Do any people who have had braces know? Apparently It's a whitey paste that also makes your teeth whiter afterwards.This reason I ask this, is because I have a top brace, but no bottom and my teeth have gone very discoloured, but the only way to keep my teeth moving is to have the bottom brace as well, and I don't want too because they will make my teeth discoloured.Does anyone know what I should do?And what is it they use to get rid of the cement? Does it really whiten your teeth? I know the whitey paste idea is not a rumour, my friend came in with no braces on, with really white teeth and she said they used a white paste to scrape off the glue.ANY IDEAS?

- Well, I still have my braces, but I've had to get the cement off a couple times, and what he'd do is take this thing that you are not allowed to look at, you have to keep your eyes shut, and he takes it off, you can't swallow otherwise you swallow the cement, it is kinda gross, I think he is filing it when he does that. I've never heard of a white paste but maybe they do something different.

- Q: whats cheaper stamped cement-tile-or a cement overlay

- If it is outdoors do cement, outdoor ceramic tile is expensive. Indoors I would do ceramic tile.

- Q: I've had braces and had a permanent lower retainer put in. Well the dentist removed it today and never scrapped the cement off of the back of my teeth. Anyone know of a way that I can get it off at home without having to go back to the dentist?

- TATE, DENTAL CEMENT MUST BE PROPERLY REMOVED WITH DENTAL INSTRUMENTS SO NO DAMAGE OCCURS TO THE TEETH. THIS CEMENT IS VERY STRONG AND ONLY CERTAIN DENTAL TOOLS AND PROPER KNOWLEDGE IS THE WAY TO GO.

Send your message to us

Highest quality for Portland cement 42.5/52.5/Type I Standard/TYPE I/II

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords