Floor Tile for Building Project Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Floor Tile For Building Project Cement Tile

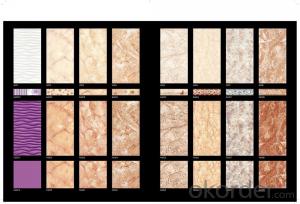

1.Glazed cement tile

2.W.A:lass than 0.5%

3.600x600,300x600,300x300mm

4.used:floor,wall

5.glossy glaze

Details of Floor tile for building project cement tile

Item No | P60621 |

Material | porcelain |

Finish | 3d printing |

Water absorption | 0.5 |

Size |

600x600.600x300,300x300,etc |

Thickness | about 9.5mm |

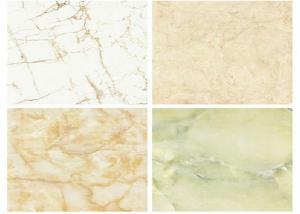

Color | white,pink,green and many color are available |

Packing | carton with wooden pallet,seaworthy |

usage | floor and wall |

Tenique | Glazed Tiles |

Test report:

Packing details:

size | pcs/ctn | kg/ctn | sqm/ ctn | ctn/plt |

300x300 | 11 | 22 | 0.99 | 62 |

300x600 | 8 | 32 | 1.44 | 40 |

600x600 | 4 | 32 | 1.44 | 40 |

- Q: cement render finishesAbout us:We are factory with professional Ramp;D team and perfect after-sales service team, We are a manufacturer with national certificate, Each machine is inspected strictly before delivery. You are welcome to visit our factory anytime.cement render finishes

- video rendering machine cement render machine how to cement plaster a wall mortar rendering machine cement wall plastering machine plastering machine for wall auto wall rendering machine gypsum plaster machine spray plastering machine india concrete plastering machine

- Q: The cement industry is an example of an undifferentiated oligopoly. The automobile industry is a differentiated oligopoly.

- does it matter to you what 'brand' of cement the builder of your appt block used? Or does it matter moer what brand is your car/dream car? Certainly the auto industry is more likely to advertise to the general public. Afterall the target of the cement companies is more likely to be developers, builders... Hence they would advertise in specialised journals rather than papers for the general public. Hence, I'd say that the auto industry is mor elikely to advertise using different media, whereas the cenment industry woud probably focus on industry publications.

- Q: the big pieces came from a old cement gold fish pond in my yard .

- best bet sledge hammer easy way eletric jack hammer home depo rents them good luck

- Q: I'm writing an essay on cement, one of the requirements is to define technology, but i don't just want a definition in the middle of my essay, so i need to make one paragraph relating technology with cement. any advice, pointers, ideas, would be greatly appreciated!

- Well, you see, good cement/technology is strong, and much better and more useful things can be bulit upon it, but weak cement/technology doesn't last long, and nothing good can be built on it.

- Q: Are they just two different terms for the same thing?

- Cement is made from ground and fired limestone and gypsum. It is a fine dry powder and when water is added can be a glue-type material. Concrete is a combination of cement, sand, gravel and water. When combined in specific proportions this combination makes concrete.

- Q: What is the history of cement? How is it manufactured? What are the types of cements?My nephew wants to be a cement man in the future, and needs those info. He needs my contacts to help him evaluate if he actually likes the cement man idea in particular and the cement industry in general. Thanks for your help.

- Just how long have condoms been around? The answer might surprise you. Most people think that condoms have been around and in use for a few hundred years, but they are wrong. On a cave wall in France is a painting of a man using a condom. This painting is between 12,000 and 15,000 years old, so condoms have been around for thousands of years, not hundreds. Condoms have been made out of a variety of materials over the years including linen, animal intestines, oiled paper, latex, and polyurethane. Currently only latex, polyurethane, and animal tissue condoms are available on the US market, but only the latex condoms have been shown to be effective in preventing the spread of STDs.

- Q: when putting down cement backboard on the floor for tiling, can you just nail it down and skip mortar or adhessive?

- I always use screws to hold down the backer board.

- Q: A bag of cement weighing 350 N hangs in equilibrium from three wires as suggested in the figure below. Two of the wires make angles θ1 = 61.0° and θ2 = 41.0° with the horizontal. Assuming the system is in equilibrium, find the tensions T1, T2, and T3 in the wires.T1 = T2 = T3 =

- The tension in the third wire is equal to the weight of the bag of cement. The sum of the vertical components of the tension in each of the other wires is equal to the tension in the third wire. So, the sum of the vertical components of the tension in each of the other wires is equal the weight of the bag of cement. Vertical component = T * sin θ For the left wire, vertical component = T1 * sin 61 For the right wire, vertical component = T2 * sin 41 Eq#1: T1 * sin 61 + T2 * sin 41 = 350 Since the system is in equilibrium, the magnitude of the horizontal components of the tension in each of the other wires is equal. Horizontal component = T * cos θ Eq#2: T1 * cos 61 = T2 * cos 41 T1 = T2 * cos 41/cos 61 Substitute (T2 * cos 41/cos 61) for T1 in Eq#1, and solve for T2. T2 * cos 41/cos 61 * sin 61 + T2 * sin 41 = 350 T2 * (cos 41/cos 61 * sin 61 + sin 41) = 350 T2 = 350 ÷ (cos 41/cos 61 * sin 61 + sin 41) = 173.4741944 N This is approximately 173.5 N Substitute 173.4741944 for T2 in Eq#1 and solve for T1. Eq#1: T1 * sin 61 + 173.4741944 * sin 41 = 350 T1 = (350 – 173.4741944 * sin 41) ÷ sin 61 = 270.0495844 N This is approximately 270 N. To check this answer, substitute both answers in Eq#2: T1 * cos 61 = T2 * cos 41 270 * cos 61 = 173.5 * cos 41 131 = 131 This proves that the tensions are correct! I hope that my work has helped you understand how to solve this type of problem.

- Q: We want to remove the carpet and install wooden vinyl flooring. We were thinking about putting cement board in order to make the floor flat.We were thinking that it would be a better option as oppose to laying the flooring on the wood. Would it be a good idea to lay down cement board?Should we just lay the vinyl on the wood?

- as long as you're putting the cement board over a solid surface and not joists. Make sure the smooth side is up and all the joints are tight.

- Q: I have a small problem I wish to dispose of........

- damn it do i have to help you again? i'll stop and get the cement so i can show you i'll be right over 9 beers up

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$15 million |

| Main Markets | Asia, Middle East |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese;Arabic |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Floor Tile for Building Project Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords