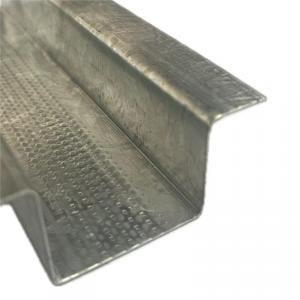

Aluminum Angle Plate

Aluminum Angle Plate Related Searches

Aluminum Angle Aluminum Diamond Plate Angle Angle Aluminum Aluminum Triangle Plate Aluminum Metal Plate Bending Aluminum Plate Aluminum Round Plate Aluminum Wall Plate Aluminum Grill Plate Aluminum Surface Plate Aluminum Cooking Plate Aluminum Profile Plate Aluminum Flat Plate Aluminum Square Plate Aluminum Caul Plate Aluminum Spinning Plate Aluminum Plate Panels Aluminum Angle Iron Aluminum Dimond Plate Aluminum Base Plate Bending Plate Aluminum Aluminum Pressure Plate Aluminum Mold Plate Aluminum Tool Plate Aluminum Bent Plate Aluminum Vin Plate Aluminum Gland Plate Aluminum Paper Plate Aluminum Oxide Plate Aluminum Hot PlateAluminum Angle Plate Supplier & Manufacturer from China

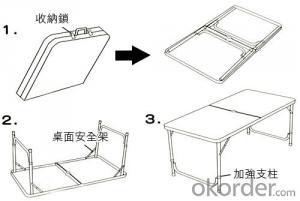

Aluminum Angle Plate is a type of metal product made from aluminum, which is known for its lightweight, corrosion resistance, and high strength. These plates are commonly used in various industries due to their durability and versatility. They can be found in construction, automotive, aerospace, and many other applications where a strong yet lightweight material is required. The product is available in different sizes, thicknesses, and finishes, catering to the diverse needs of various projects.Aluminum Angle Plate is widely used in structural applications, such as framing, bracing, and support systems. Its lightweight nature makes it an ideal choice for applications where weight is a critical factor, such as in the aerospace and automotive industries. Additionally, its corrosion resistance makes it suitable for outdoor applications and in environments where exposure to moisture and chemicals is common. The product's high strength-to-weight ratio also makes it a popular choice for load-bearing applications, where a strong yet lightweight material is essential.

Okorder.com is a leading wholesale supplier of Aluminum Angle Plate, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminum Angle Plate they supply meets the highest standards of performance and reliability. Their extensive inventory allows customers to find the exact specifications they require, making Okorder.com a one-stop solution for all Aluminum Angle Plate needs.

Hot Products