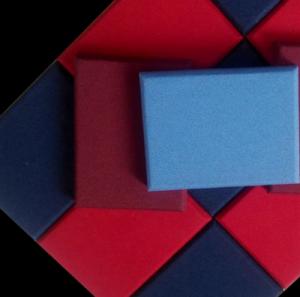

Acoustic fiberglass suspended decorative wall panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acoustic fiberglass suspended decorative wall panels

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

CMAX

Ceiling Tile Shape:

Square

Ceiling Tile Type:

Fiberglass Ceilings

Product name:

fiberglass wall panelling for sale

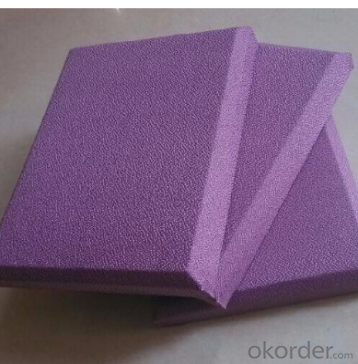

Material:

Glass fiber

Standard size:

600*600 mm, 600*1200 mm, 600*1800 mm

Thickness:

12mm, 15mm, 20mm,25 mm

Advantage:

Heat/sound insulation, sound absorption, environmental protection

Application:

KTV, Hotel, Hanquet hall,Gymnasium, Multi-function

Packing:

15 PCS/CTN or as required

Certification:

ISO9001

MOQ:

100 sqm

Payment:

T/T, Trade assurance, L/C at sight,

Packaging & Delivery

Packaging Details

Packed in cartons for acoustic decorative fiberglass wall panelling for sale

Port

Shanghai, Qingdao,Lianyungang,Ningbo China

Lead Time :

15 days after deposit

Product Description

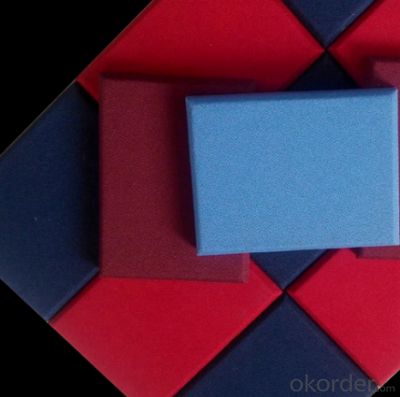

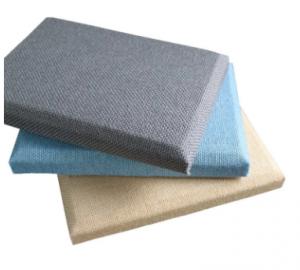

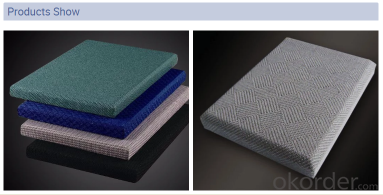

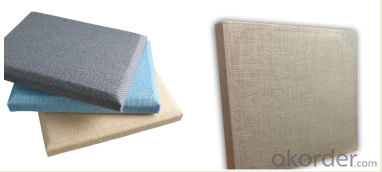

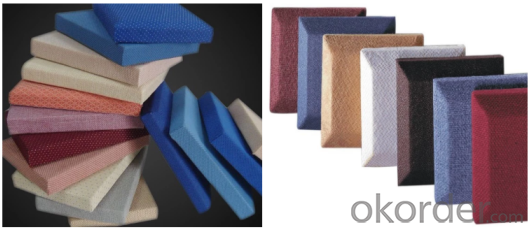

Acoustic Wall Panel Series

Soften space, constant temperature warm effect, the integration of decoration and whole frequency sound absorption. Optional colors and fabrics, meeting the varied acoustic and decorative requirement

Product Name | ISO certificate decorative fabric wrapped fiberglass acoustic wall panel |

Material | Glass fiber |

Frame | flame-retarded resin, wooden, aluminium |

Volume weight | ≥70~100 kg/m³ |

Fire performance | B1 |

Environmental performance | class E1 |

Thickness | 12 mm, 15 mm, 20 mm, 25 mm or 50 mm Customized |

Certification | ISO 9001, ISO 14000 |

Application | KTV, Hotel, Hanquet hall, Gymnasium, Multi-function room, Audio-video room, other acoustic required places |

Product features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

Packing & Delivery

Packing Details : Standard Package

Loading information for regular size:

Size | Thickness | Packing ( PCS /CTN ) | Quantity( 40 HQ ) |

600mm*600mm | 12 | 25 | 13300 PCS /532 CTNS /4788㎡ |

600 mm*1200mm | 12 | 25 | 6650 PCS /266 CTNS /4788㎡ |

600mm*600mm | 15 | 20 | 10640 PCS /532 CTNS /3830.4㎡ |

600 mm*1200mm | 15 | 20 | 5320 PCS /266 CTNS /3830.4㎡ |

600mm*600mm | 20 | 15 | 7980 PCS /532 CTNS /2872.8㎡ |

600 mm*1200mm | 20 | 15 | 3990 PCS /266 CTNS /2872.8㎡ |

600mm*600mm | 25 | 12 | 6384 PCS /532 CTNS /2298.2㎡ |

600 mm*1200mm | 25 | 12 | 3192 PCS /266 CTNS /2298.2㎡ |

- Q: How to do with glass fiber wall anti-crack

- For glass fiber is also used to see you are used in the external walls or interior walls, wall materials are different, a lot of things are not applicable once. Do not apply their own norms. And a slap to shoot the whole law

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: FRP can be used to make walls

- FRP can be used to make walls. FRP Product Category: Glass cans, glass cans, hydrochloric acid storage tanks, sulfuric acid storage tanks, reaction tanks, preservative tanks, chemical storage tanks, transport tanks, food cans, fire cans, etc. Glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, Towers: drying tower, washing tower, desulfurization tower, acid mist purification tower, exchange column; Bathroom: bathroom chassis, bathroom roof.

- Q: What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q: What should the overall wardrobe design should have?

- 1, wardrobe side panels and laminates and other places need to bear the weight of 18mm thickness of the three polyamine in the density of fiberboard, the cabinet board to the national authority of the test report, in line with national mandatory standards GB18584-2001 standard, formaldehyde release The amount of ≤ 1.5mg / L, moisture content between 5-11; backplane does not require load-bearing, you can use 5mm thick to make, this can save costs, conditions permit, the door and backplane thickness should be 9mm. For the hanging cabinet, the back plate on the need to use 18mm thickness, density standard 0.6-0.9g / cm3, to enhance the stability of the hanging cabinet; ???? 2, although the overall wardrobe is tailor-made products, but there are standard and non-standard points, the standard parts is the manufacturer in accordance with the specifications of the plate to calculate the production, you can achieve maximum use of the board, the edge is generally uniform, Black line and sawtooth printed; non-standard parts will waste a lot of sheet metal, so the price, non-price will be more expensive;

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- Fiberglass is a glass fiber reinforced plastic commonly known as it is a glass fiber reinforced material, synthetic resin as the base material of the composite products. FRP has a good anti-corrosion properties. Especially the water and dilute the concentration of acid Liquid, and can show its superiority, and FRP lightweight high strength specific gravity of 1.7-1.8 is a quarter of steel.For the insulation: you can use polyurethane foam. With light weight. High strength. Low thermal conductivity. Non-absorbent and other characteristics. Has been widely used in travel. Building. Cold storage. Refrigerator. Petrochemical. Indoor air conditioning.

Send your message to us

Acoustic fiberglass suspended decorative wall panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords