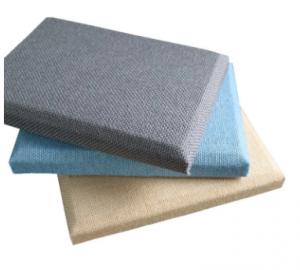

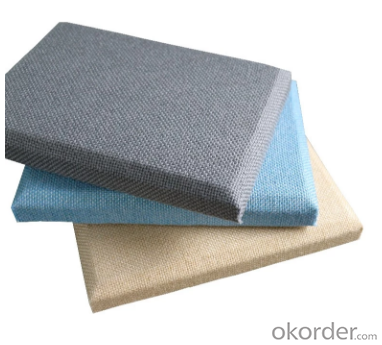

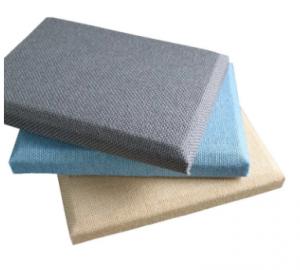

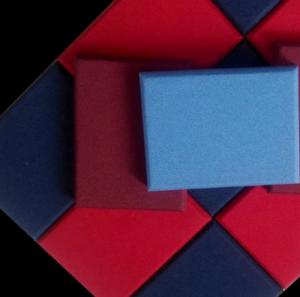

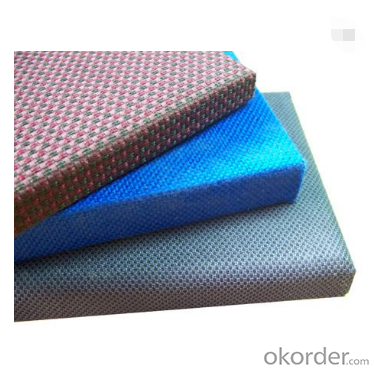

Acoustic fiber glass wall panel for bed room

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acoustic fiber glass wall panel for bed room

Specification:

Standard Size: 600mm*600mm, 600mm*1200mm…

Standard Thickness: 25, 30, 40, 50mm…

Edge Detail: Square, Bevel

Technical Data of Fiberglass Wall Panel:

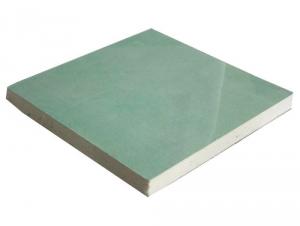

Material: Torrefaction compounded high density fiberglass wool

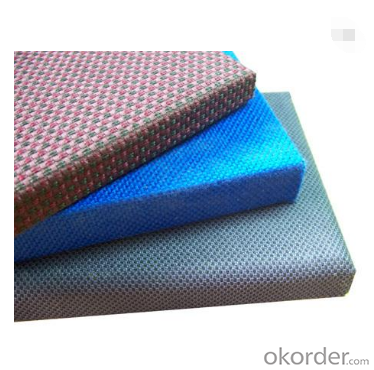

Facing: wrpped with special decorative fabric

Fire-resistant: Base board: Class A, Finished board:Class B2

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Acoustic fiber glass wall panel for bed room

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Commercial Halls,Classrooms,Offices,Libraries,Shopping Centers,Music Rooms,Auditoriums,etc.

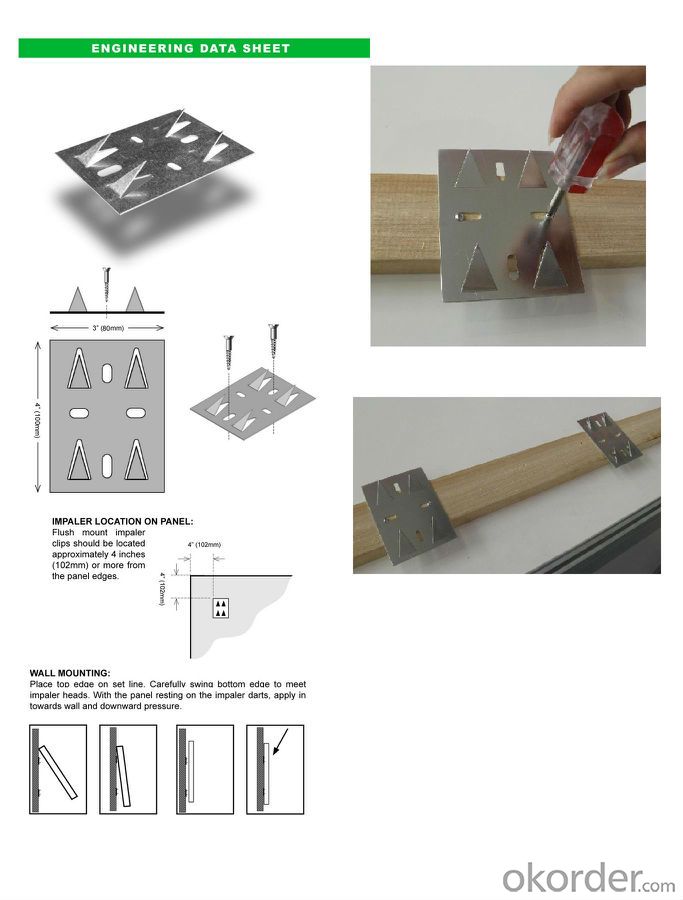

How to install:

Acoustic fiber glass wall panel for bed room

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: FRP can be used to make walls

- FRP can be used to make walls. FRP Product Category: Glass cans, glass cans, hydrochloric acid storage tanks, sulfuric acid storage tanks, reaction tanks, preservative tanks, chemical storage tanks, transport tanks, food cans, fire cans, etc. Glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, Towers: drying tower, washing tower, desulfurization tower, acid mist purification tower, exchange column; Bathroom: bathroom chassis, bathroom roof.

- Q: What should the overall wardrobe design should have?

- 1, wardrobe side panels and laminates and other places need to bear the weight of 18mm thickness of the three polyamine in the density of fiberboard, the cabinet board to the national authority of the test report, in line with national mandatory standards GB18584-2001 standard, formaldehyde release The amount of ≤ 1.5mg / L, moisture content between 5-11; backplane does not require load-bearing, you can use 5mm thick to make, this can save costs, conditions permit, the door and backplane thickness should be 9mm. For the hanging cabinet, the back plate on the need to use 18mm thickness, density standard 0.6-0.9g / cm3, to enhance the stability of the hanging cabinet; ???? 2, although the overall wardrobe is tailor-made products, but there are standard and non-standard points, the standard parts is the manufacturer in accordance with the specifications of the plate to calculate the production, you can achieve maximum use of the board, the edge is generally uniform, Black line and sawtooth printed; non-standard parts will waste a lot of sheet metal, so the price, non-price will be more expensive;

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- Fiber mesh, also known as reticular fiber, reticular polypropylene fiber, is a polypropylene as raw material, through a special process from manufacturing. The appearance of a number of fiber monofilament cross-linked from the network structure.

- Q: Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production process of glass fiber generally includes: raw material procurement, according to the formula for mixing, and then transported to the glass furnace for melting, clarification, through the operating channel flow to the drawing board, sizing agent after drawing through the drawing machine to form the original wire (Usually with yarn, weaving, chopping, puffing, twisting, etc.) or for sale (direct yarn)

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- With my experience I think FRP is better, long life, polyurethane foam and FRP is better, the price comparison is not clear, I only know that FRP: give you a unit price of 1.2 thick, 26 per square, 1.5 Thick ,,, 30 per square ;; Polyurethane foam unit price; 900 per cubic.

- Q: Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

Send your message to us

Acoustic fiber glass wall panel for bed room

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches