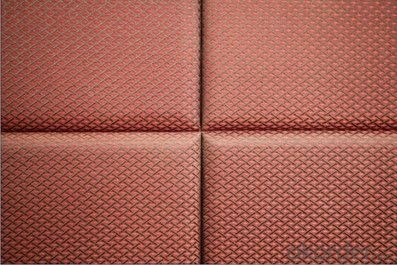

Fiberglass Acoustc Wall Panels with Different Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

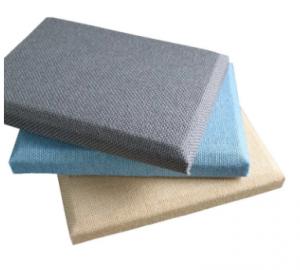

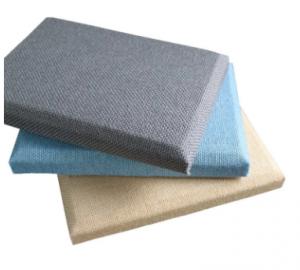

Fiberglass acoustic wall panel is made from high density fiberglass wool as the base material, with fabrics on the surface; four edges are securely glued. Suitable for the indoor wall panels of public place, such as the meeting room, school, studio room, cinema and theatre etc, effectively reduce the noise level. It is an excellent sound absorption product.

Specifications:

Density: 100kgs/m3, 120kgs/m3

Thickness: 25mm, 30mm, 40mm, 50mm, 75mm

Size: 600*1200mm, 1200*1200mm, 600*1800mm, 600*2400mm and etc.

Surface: Different kinds and colors of fabrics

Edge: Square, Bevel

Technical Data:

Fire proof: Base board Class A incombustibility, surface fabrics incombustibility can be customized.

Thermal Insulation: ≥0.5 (m2·k/w)

Damp-proof: Max 90% R/H at 40℃

Moisture content: ≤1% (JC/T670-2005)

Environment friendly: Product and package can be recycled.

Clean: wipe with soft fabric

Features:

1. Excellent performance of sound absorption, effectively reduce noise levels.

2. Various decorative fabric and colors can be applied, produces an effect of luxury and elegant.

3. Stable dimension under the high temperature and humidity.

4. Good thermal insulation performance, energy saving.

5. Easy installation and adjustment.

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The softness of the mesh cloth does not depend on the quality of the mesh cloth. Depending on how much glue is applied. Used in the wall, of course, is a lot of glue, and can increase the degree of alkali resistance. Now there is a kind of urine glue, painted out really hard But this is not alkaline.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q: What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is GRC and can I paint it?

- GRC popular understanding of it, refers to the FRP to do the components of profiles. Can be made into any shape, such as sculpture, murals, decorative lines, etc., generally have a good finished product for you to choose. The advantage is high hardness and light weight and the price is not expensive. Is now a large number of decorative materials used. Can be based on your request, do oily or metallic paint, using the basic are spraying process. Another: custom need to open a separate mold costs, so if a small amount of custom, it is more expensive friends.

- Q: What is grc widget

- GRC (Glass-fiber Reinforced Cement) glass fiber reinforced cement composite material abbreviation, from the European and American technology, is to alkali-resistant glass fiber, cement, sand and other composite materials according to a certain ratio of mixing, in the mold watering molding, production Modeling rich, texture and diverse products, are widely used in domestic and international characteristics of the building.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- Interior wall whitewashed shear wall need to hang fiber mesh, can make the paint more stable wall, inhibit the formation and development of cracks.

- Q: Wall material that kind of environmental protection?

- Diatom mud soft bag wallpaper floor wall is now a lot of latex paint is also very environmentally friendly

- Q: Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

Send your message to us

Fiberglass Acoustc Wall Panels with Different Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords