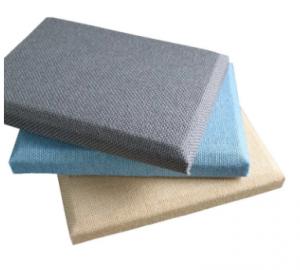

Fiberglass Wall Panel with Fabric HC-388

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 25mm, 40mm, 75mm and etc.

Size: Standard 1200*600mm, max 2700*1200mm and etc.

Surface: Decorative or Fiberglass Fabrics in different colors

Edge: Square, Bevel

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound absorption, sound insulation, insulation, ring glass board ceiling construction process

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: FRP can be used to make walls

- FRP can be used to make walls. FRP Product Category: Glass cans, glass cans, hydrochloric acid storage tanks, sulfuric acid storage tanks, reaction tanks, preservative tanks, chemical storage tanks, transport tanks, food cans, fire cans, etc. Glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, Towers: drying tower, washing tower, desulfurization tower, acid mist purification tower, exchange column; Bathroom: bathroom chassis, bathroom roof.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- Lightweight aggregate concrete partition board: is made of lightweight aggregate concrete slab, which is suitable for ordinary building grade. Lightweight aggregate concrete is made of natural light aggregate (such as pumice) or artificial light aggregate (such as ceramic) or industrial waste light aggregate (such as slag beads) plus cement and water mixed with concrete. Lightweight aggregate concrete and ordinary concrete is the difference between light aggregate concrete without stones, and some of his aggregate can float on the water.

- Q: What is grc widget

- GRC (Glass-fiber Reinforced Cement) glass fiber reinforced cement composite material abbreviation, from the European and American technology, is to alkali-resistant glass fiber, cement, sand and other composite materials according to a certain ratio of mixing, in the mold watering molding, production Modeling rich, texture and diverse products, are widely used in domestic and international characteristics of the building.

- Q: The difference between GRC lightweight partition board and ceramic plate

- GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, It is easy to avoid the wet construction, improve the construction environment, save the land resources, light weight in the building to reduce the load, (is the Clay brick 1 / 6-1 / 8 weight) to reduce the foundation and beam, Zhu reinforced concrete, reduce the total cost of the project, expand the use of area. Is the non-load-bearing parts of the building to replace clay brick the best material

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- If the insulation from the good, corrosion-resistant aspects to consider, then the inorganic glass fiber reinforced plastic composite panel better, for the following reasons: Inorganic glass fiber reinforced high temperature. (Under normal circumstances, the temperature of 400 degrees Celsius to keep the product is not deformed). Inorganic glass steel anti-aging, 20 years the product is not deformed. Clean air, can absorb air of carbon dioxide. high strength. Good waterproof performance. Light weight, second only to plexiglass steel. Low cost, low price of raw materials floating. Insulation, sound absorption. Not burning After disposal, it can be used for landfill. It is an ideal environmental protection material for water, soil and air.

Send your message to us

Fiberglass Wall Panel with Fabric HC-388

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords