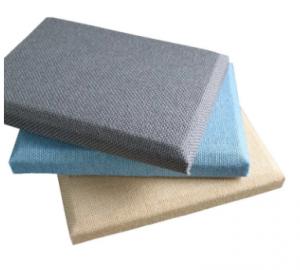

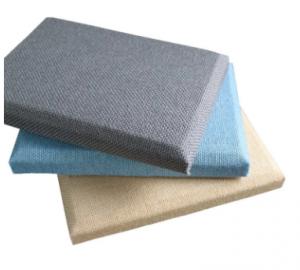

Fiberglass Wall Panel with Fabric HC-389

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 25mm, 40mm, 75mm and etc.

Size: Standard 1200*600mm, max 2700*1200mm and etc.

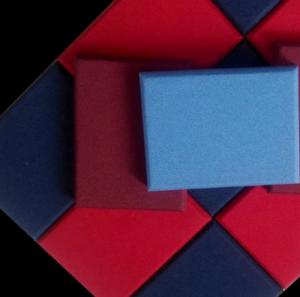

Surface: Decorative or Fiberglass Fabrics in different colors

Edge: Square, Bevel

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q: How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The composite material is mainly composed of two parts: the reinforcing material and the base material: Reinforcing material: does not constitute a continuous phase in the composite material to the main mechanical properties of composite materials, such as fiberglass in the glass fiber, CFRP (carbon fiber reinforced plastic) in the carbon fiber is reinforced. A resin in a single material, such as glass fiber reinforced plastic (GRP), which constitutes a continuous phase of a composite material, is a matrix. Y

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- If the insulation from the good, corrosion-resistant aspects to consider, then the inorganic glass fiber reinforced plastic composite panel better, for the following reasons: Inorganic glass fiber reinforced high temperature. (Under normal circumstances, the temperature of 400 degrees Celsius to keep the product is not deformed). Inorganic glass steel anti-aging, 20 years the product is not deformed. Clean air, can absorb air of carbon dioxide. high strength. Good waterproof performance. Light weight, second only to plexiglass steel. Low cost, low price of raw materials floating. Insulation, sound absorption. Not burning After disposal, it can be used for landfill. It is an ideal environmental protection material for water, soil and air.

Send your message to us

Fiberglass Wall Panel with Fabric HC-389

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords