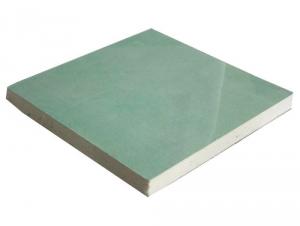

Fiberglass Wall Panels for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

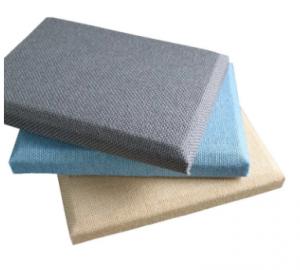

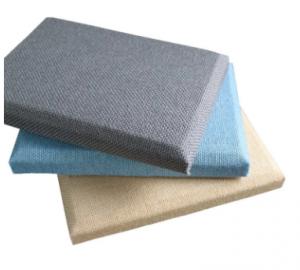

Fiberglass acoustic wall panel is made from high density fiberglass wool as the base material, with fabrics on the surface; four edges are securely glued. Suitable for the indoor wall panels of public place, such as the meeting room, school, studio room, cinema and theatre etc, effectively reduce the noise level. It is an excellent sound absorption product.

Specifications:

Density: 100kgs/m3, 120kgs/m3

Thickness: 25mm, 30mm, 40mm, 50mm, 75mm

Size: 600*1200mm, 1200*1200mm, 600*1800mm, 600*2400mm and etc.

Surface: Different kinds and colors of fabrics

Edge: Square, Bevel

Technical Data:

Fire proof: Base board Class A incombustibility, surface fabrics incombustibility can be customized.

Thermal Insulation: ≥0.5 (m2·k/w)

Damp-proof: Max 90% R/H at 40℃

Moisture content: ≤1% (JC/T670-2005)

Environment friendly: Product and package can be recycled.

Clean: wipe with soft fabric

Features:

1. Excellent performance of sound absorption, effectively reduce noise levels.

2. Various decorative fabric and colors can be applied, produces an effect of luxury and elegant.

3. Stable dimension under the high temperature and humidity.

4. Good thermal insulation performance, energy saving.

5. Easy installation and adjustment.

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- In any case, when the batch wall putty, is not the use of steel wire mesh, and if it is leveling with cement mortar, then you should use the wire mesh.

- Q: What is the quality of the light barrier now?

- . Increased use of building area: the wall can increase the use of an area of 8-10% or more, is the property development buyers and sellers are happy to accept.

- Q: FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q: What are the lightweight wallboard materials?

- The traditional brick wall has some limitations, and now the building has begun to speak lightweight wall materials used in the external walls, the effect is good, in the partition wall material selection, lightweight partition material can And bricks to match. And the new lightweight partition material, energy saving and environmental protection, light and easy to use, according to the current development situation, the use of brick wall material is still more. This is mainly the people affected by the traditional, the use of traditional materials feel more at ease. More solid.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The current state to promote the third generation of environmentally friendly energy-saving partition board, with moisture, earthquake noise, fire insulation, small footprint, good strength, fast construction and other advantages.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- Fiberglass is a glass fiber reinforced plastic commonly known as it is a glass fiber reinforced material, synthetic resin as the base material of the composite products. FRP has a good anti-corrosion properties. Especially the water and dilute the concentration of acid Liquid, and can show its superiority, and FRP lightweight high strength specific gravity of 1.7-1.8 is a quarter of steel.For the insulation: you can use polyurethane foam. With light weight. High strength. Low thermal conductivity. Non-absorbent and other characteristics. Has been widely used in travel. Building. Cold storage. Refrigerator. Petrochemical. Indoor air conditioning.

Send your message to us

Fiberglass Wall Panels for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords