2x4 Fiberglass Ceiling Panels - Acoustic Fiberglass Ceiling Well Quality 120k Density

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Ceiling

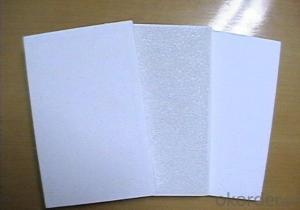

The tiles are manufactured from high density fiberglass wool.The visible face has a decorative fiberglass tissue and the back of the tile is covered with normal tissue.The four edges of the tile are sealed and have grooves. It can be jointed together without suspended system. The tiles will cover the suspension system after installation. They are are suitable for loe flap ceiling space and concrete-made, wooded-made or gymsum ceiling.

Installation method:

Use screw to fix the smooth roof. The tiles can be connected after making grooves on each two jointed edges.

Tiles are easy to trim and install

Both inches and metric grids are available

Main Characteristic:

Non-combustible

No sagging,wrapping or delaminating

Green building material

Excellent sound absorption

Application:

Halls,classrooms,offices,shopping centers.etc.

Acoustic fiberglass ceiling contains a better perfomance in tension strong, light weight, so it is easy to trim and install for interior decoration, with T-grids for suspension system or glue, nail or good material could come with fiberglass ceiling baord. Thus an excellent artical work need a high quality acoustic ceiling board, also high quality.

Energysaving is a trend for our 21' era, new product like fiberglass ceiling tile could in place of traditional products one day. Which depends on functional characters: little deflection of geometry dimention, no radiocative property, specific activity of 226Ra: Ira ≤1.0 and specific activity of 226 Ra 232 Th, 40 K: Ir ≤ 1.3. Both products and packages can be recycled.

- Q: We had a plaster ceiling that was cracking. We put new drywall up over the ceiling and finished the seams. We have finished drywall before, but only on wall. Apparently ceilings are alot harder. We have a tetured wall and really do not want a texture on the ceiling (we would never be able to match the textures anyway). We have primed and painted the ceiling with flat paint and can see the seams. We do not have alot of light in the room either. Does anyone have any suggestions to hide the seams? Thanks

- This Site Might Help You. RE: help! Finished drywall on a ceiling and you can see the seams? We had a plaster ceiling that was cracking. We put new drywall up over the ceiling and finished the seams. We have finished drywall before, but only on wall. Apparently ceilings are alot harder. We have a tetured wall and really do not want a texture on the ceiling (we would never be able to...

- Q: Fireproof fireproof glass fireproof shutter door What is it?

- You can be very intuitive to understand the fire resistance for the decorative parts, fire cut off, fire glass, fire shutter doors have in common, that is played an effective isolation; it is both functional, but also has the role of split space!

- Q: We just had our first child, and his room is right above the garage. It is noticebly colder in his room, especially the floor. I used the plastic window kits and that helped, however, the floor is still extremely cold and I would like to at least check the insulation in the garage ceiling. Right now there is drywall on the ceiling, but I have no qualms about ripping it down, not real worried what it looks like. What should I look for...I believe there is very old (50 years) fiberglass insulation but i'm not 100% sure. If there is the old insulation there...should I look to replace it? If so, with what R value...Is this a project that someone without specific experience in the field could complete? I'm pretty handy but certainly not a pro. I'm not worried at all how it looks in the garage.

- This project can be easily completed by someone with little to no experience. Since you believe the insulation is 50+ years old, your best coarse of action is to tear out the drywall and existing insulation and replace with new R-30 insulation. Fiberglass insulation starts to degrade after 50 yrs. R values vary on your location and climate, but a in general an R-30 batts would work for this application.

- Q: I'm afraid that joint compound might not adhere well to plywood.

- It will stick just fine. I have painted wood paneling this way too...by taping all the seams just like you would dry wall, and filling the grooves as well. Once it is sanded and painted it looks just like drywall.

- Q: We just bought a house and our ceiling has the cottage cheese texture to it and it is cracked and broken in many placed so my husband wants to just take it off. I have told him that it may contain asbestos but he thinks he can do it on his own. So we are going to get it tested and if it does he just wants to remove it himself. My question is, is this a job anyone can do?

- As sparkles said asbestos is a hazardous materials.. wow if hubby wants to do it himself best of british luck. To start with he is going to need complete head mask and breathing gear filters and full overalls ,, no part of body to be exposed, the material has to be dampered as its pulled out and completely wrapped in plastic and taped up and buried with minimum cover of 6ft. Wash all clothes and then burn 'em You think I joke!! I kid you not.. asbestous dust can linger and if breathed in collects on the lungs then BINGO ..Asbestosis CANCER WITH A BIGGG C. Take it from someone who has it & i guarantee u dont want it.. So sit down with a glass of wine or beer , think about it and get the experts in you only have one life and the experts have the liscence to do it & get rid of it. Take the old man for a second honeymoon and leave it to them..... that's the best advice you can get for free. ciao.. but the fine if you get caught in Aussie land would NOTcompensate for the experts...

- Q: Hi,The felt (or whatever it is made of) ceiling in my car is falling down. I have scraped most of the residual glue off the ceiling made out of fiberglass and what I can off of the carpet/felt part. I've tried a couple of different types of two sided tape and can't get it to stick. Does anyone have any ideas?Thanks in advance...

- you need to take the head liner backing down , its held up by some screws or clips, careful not to break it, then go to a good automotive store and get some HEAD LINER adhesive , its made for the job work where you have plenty of room follow the directions then put it back in the car a second person to take out & put back in is helpful

- Q: What is the best material for interior decoration

- Pure natural, environmentally friendly, little processed, is the best,

- Q: I am trying to find least expensive method to install support for spray-on closed cell foam insulation between ceiling joists in attic where there is no support beneath the rafters (only a drop ceiling). This is a large fire station that currently has fiberglass bat insulation between the rafters. Any ideas are welcome. Thanks, Bob

- The plastic might tear or sag when the weight of the foam is applied. You could staple thin sheets of underlayment or OSB to the bottom of the joists then spray the foam from the top. Basically, you are trying to keep the place warm that has no ceiling and any heat goes up and around the drop ceiling, thru the insulation and out of the building. That's how I understand your problem. Maybe you should just remove the suspended ceiling, nail up drywall and use the existing fiberglas between the joists with another fiber glass layer perpendicular to the joists on top of the old stuff. Or blown in insulation. You better test the foam for flamability. Some of that stuff can burn and emit toxic fumes that will kill a whale. The other disadvantage of foam is that moisture will not penetrate it, so you might have condensation on the ceiling. Drywall will allow moisture to pass thru and sheathing and Tyvex are also designed to breath. You don't want to trap moisture inside any place you live. That would create a whole bunch of problems. Black mold being one of them.

- Q: What signs on plastic products are non-toxic

- Material products should be above the regeneration cycle mark the triangle, there is a number, the following is PP or PE. The number is between 1-6, the greater the number that the higher the regeneration effect. Write 1 for the polyethylene terephthalate Common mineral water bottles, carbonated beverage bottles and so on. Heat to 70 ℃ easy to deformation, There is material harmful to the human body. No. 1 plastic goods with 10 months later, May release the carcinogen DEHP. Can not be placed in the car in the sun; do not pretend to wine, oil and other substances

- Q: What is the relationship between the two? Or who is engaged in the electronics industry, can give me talk about the industry's industrial chain and technical process? Thank you.

- The characteristics of glass fiber ?? The concept of glass is generally hard and fragile objects, and is not suitable as a structural material, but if it is made of silk, its strength is greatly increased and has a softness, so with the shape of the resin can finally become a good structural material. Glass fiber with its diameter smaller its strength increased. As a reinforcing fiber glass fiber has the following characteristics, these features make the use of glass fiber far more than other types of fiber to a wide range of development speed is also far ahead of its characteristics are listed below:

Send your message to us

2x4 Fiberglass Ceiling Panels - Acoustic Fiberglass Ceiling Well Quality 120k Density

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords