Frequency Inverter VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

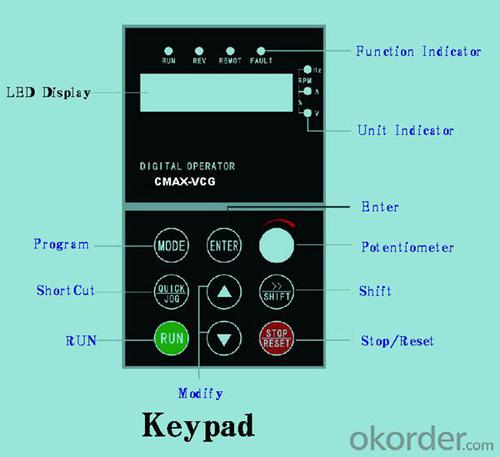

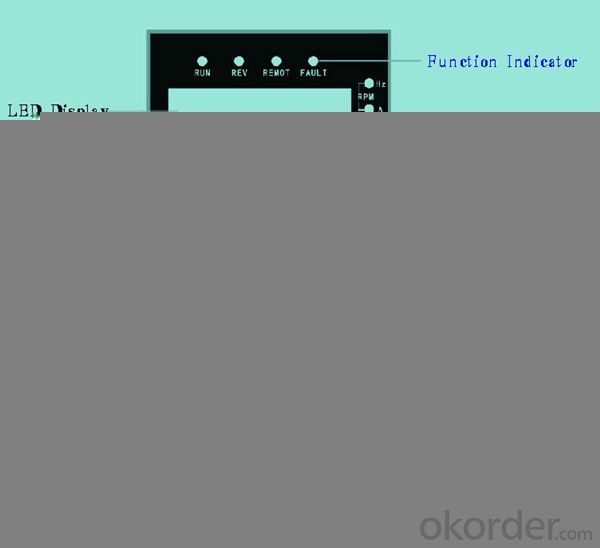

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: Frequency converter, fault, contact action

- Frequency converter is the application of frequency conversion technology and micro electronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment. The frequency converter is mainly composed of rectifier (AC DC converter), filter, inverter (DC AC converter), brake unit, drive unit, detection unit, micro processing unit and so on. Inverter by internal IGBT drive voltage and frequency off to adjust the output power, the power supply voltage required to provide according to the actual needs of the motor, so as to achieve the purpose of speed, energy saving, in addition, there are a lot of protection drive, such as over-current, over-voltage, overload protection and so on. With the continuous improvement of the degree of industrial automation, inverter has also been widely used.

- Q: Why does the frequency converter cause interference?

- Shielded interference source: shielded interference source is an effective way to suppress interference. Usually the inverter itself with iron shielding, can not let the leaked electromagnetic interference, but the output line frequency converter is best to use steel shielding, in particular to an external signal (4~20mA signal output from the controller) control of inverter, the control signal line is as short as possible (usually less than 20m), and must use the shielded twisted pair and the main power line and the control line (AC380) and (AC220V) completely separated. In addition, the circuit of electronic sensitive equipment in the system also adopts shielded twisted pair, especially the pressure signal. All signal lines in the system must not be placed in the same pipe or slot as the main electrical line and control line. To make the shield effective, the shield must be grounded reliably.

- Q: Ask, what is the ratio of frequency converter?

- Three inverter operation indicator light, the output frequency from 0.0Hz to potentiometer set frequency and the output frequency ratio is 1:1.5:2, adjust the tone potentiometer, change the motor speed and the speed of three units, according to the proportion of linkage. The output frequency of the three inverters can be adjusted with three Trimming Potentiometer respectively.

- Q: What is called vector converter?

- The vector is what we (the mainland) says. The vector is generally used in the literature of Hong Kong and Taiwan. The meaning is roughly the same as that of Bush and bush. Vector control is mainly a concept of decoupling of motor models

- Q: How much is the motor 90KW and the frequency converter selected?Colleagues suggest 110W?The cost will be higherIs it okay to choose 90KW?

- Should be able to, in the design of the inverter in consideration of the corresponding motor power matching. Choose a large capacity, a little waste Oh! Our company choose frequency converter is one-to-one correspondence, did not choose the large capacity.

- Q: Can the motor with frequency converter directly wave the insulation?

- Frequency converter with motor, is a high-power three stage tube, C, E in the output, you directly shake insulation, measuring the pressure of the transistor. So you can't measure it.

- Q: The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- The input is AC 50Hz sine wave output frequency variable, but still want to be sinusoidal. But due to various reasons such as the efficiency and control it is not directly output sine wave. It is the original inverter with high frequency sine wave modulation is Fang Bo, will be on the radio. As the modulation principle this is also called the square wave carrier. Between hundreds to thousands of HZ. In the range of our hearing. When it can be produced by mechanical vibration equipment such as reactors will sound when conducting ]. We hear is the sound.

- Q: What are the basis of the frequency converter to choose?

- 1. the power of the inverter is selected according to the load power. How many power motors should be chosen for a multi power motor?. Size one is ok.2. frequency converter model, different uses, choose different frequency converter. For example, there are general frequency converter, fan, water pump dedicated inverter, a machine tool spindle dedicated inverter. Wait。3. when the load is large, the braking unit and the braking resistor should be selected simultaneously.4. check the motor nameplate current rating (no nameplate rated current). The rated current of the inverter is greater than the maximum running current of the motor

- Q: What is the main harmonic produced by a transducer? How about the degree?

- Indirect frequency conversion has three different structure forms: (1) using controllable rectifier to change voltage, frequency conversion with inverter, voltage regulation and frequency modulation are carried out in two aspects respectively, and the two should coordinate with each other in control circuit. (2) with uncontrolled rectifier rectifier chopper inverter transformer, inverter, filter the inverter rectifier, voltage with pulse width (3) with uncontrolled rectifier rectifier, PWM inverter and inverter, this inverter device fully controlled only by controlled shutdown (such as IGBT) can output waveform is very realistic sine wave.

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- Because the motor consumes active power and consumes reactive power, and the reactive power is also occupied, the motor with 70KW can only be usedThe power is known to everyone

Send your message to us

Frequency Inverter VFD

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords