52 Tall Sheets of Aluminum Gutter Roof Aluminium Composite Panel 1100 3003 PE PVDF Price Manufacture Pre Painted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

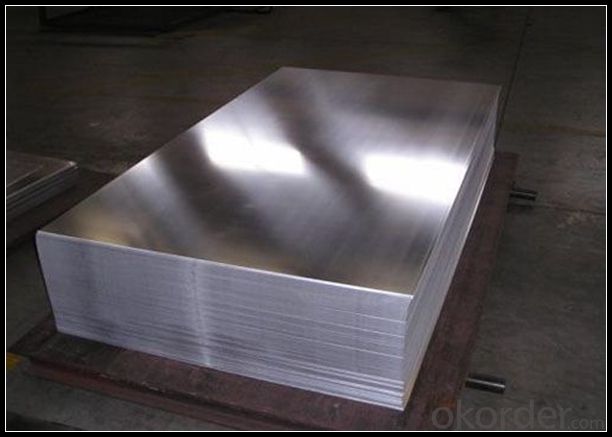

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

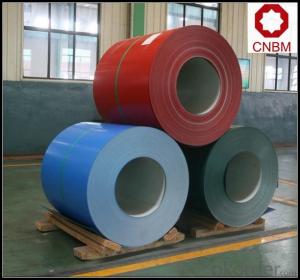

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can tolerate relies on various factors, including the composition of the alloy, thickness, and intended purpose. Generally, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, aluminum sheets can typically endure significantly higher temperatures without melting or distorting. Regarding most commercially available aluminum alloys, the maximum temperature for continuous utilization varies from 200 to 300 degrees Celsius (390 to 570 degrees Fahrenheit). Beyond this range, the material might begin to display reduced strength and heightened vulnerability to deformation or harm. Nevertheless, it is crucial to mention that the precise maximum temperature limit for a specific aluminum sheet should be determined by referring to the manufacturer's specifications or conducting specific testing. Factors like the presence of coatings or surface treatments, exposure to prolonged heat, and thermal cycling can also influence the maximum temperature tolerance of aluminum sheets.

- Q: What is an aluminum sheet?

- An aluminum sheet is a flat piece of aluminum that is typically rectangular in shape and has a consistent thickness. It is made from aluminum, which is a lightweight and versatile metal known for its corrosion resistance and high strength-to-weight ratio. Aluminum sheets are commonly used in various industries and applications, such as construction, transportation, aerospace, and manufacturing. They can be further processed, cut, shaped, or formed to meet specific requirements. Aluminum sheets are available in different grades and finishes, including smooth, brushed, and textured surfaces, providing a wide range of options for different uses.

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Yes, aluminum sheets are suitable for manufacturing electrical busbars. Aluminum is a popular choice for busbars due to its excellent electrical conductivity and lightweight properties. It can efficiently conduct high electrical currents and has low resistance, making it ideal for conducting electricity in power distribution systems. Additionally, aluminum sheets can be easily fabricated and formed into various shapes and sizes, allowing for customization and efficient installation in electrical systems.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance or provide additional protection. The process involves preparing the surface by cleaning and removing any contaminants, followed by applying a primer to improve adhesion. After the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The type of paint or coating used will depend on the intended use and the specific requirements of the application. Overall, painting or coating aluminum sheet after fabrication is a common practice and can greatly enhance its aesthetics and durability.

- Q: Are aluminum sheets resistant to impact and vibration?

- Yes, aluminum sheets are generally resistant to impact and vibration due to their inherent strength and flexibility.

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Generally, aluminum sheets exhibit resistance to corrosion from saltwater. When exposed to air or water, including saltwater, aluminum naturally develops a protective oxide layer. This layer serves as a barrier, preventing additional corrosion and safeguarding the underlying metal. Furthermore, aluminum is both lightweight and durable, making it a favored choice for numerous marine applications such as boats, shipbuilding, and offshore structures. Nevertheless, it is important to acknowledge that the level of resistance to saltwater corrosion may differ based on the specific alloy and surface treatment of the aluminum sheets. Consequently, selecting the appropriate alloy and applying protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- Yes, 101 aluminum sheets are suitable for medical equipment.

- Q: Can aluminum sheet be used for cookware?

- Yes, aluminum sheet can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity, which allows for even heat distribution and quick heating. It is lightweight, durable, and resistant to rust and corrosion. Additionally, aluminum cookware is affordable and relatively easy to clean. However, pure aluminum is a soft metal, so it is often combined with other materials, such as stainless steel or nonstick coatings, to enhance its durability and nonstick properties.

Send your message to us

52 Tall Sheets of Aluminum Gutter Roof Aluminium Composite Panel 1100 3003 PE PVDF Price Manufacture Pre Painted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords