6061 Aluminum Coil Manufacture Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

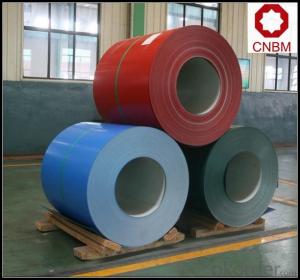

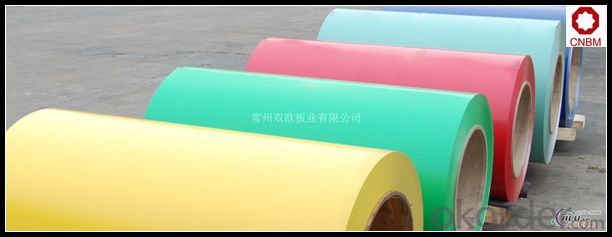

5. Image of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

6. Package and shipping of Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for architectural applications?

- Yes, aluminum coils are suitable for architectural applications. Aluminum is a highly versatile and durable material that is commonly used in the construction industry for various architectural applications. Aluminum coils offer several advantages for architectural use, including their lightweight nature, corrosion resistance, and ability to be easily formed into desired shapes and sizes. These coils can be used in architectural applications such as roofing, cladding, facades, and gutters, among others. Additionally, aluminum coils can be coated with different finishes, providing a wide range of aesthetic options for architects and designers. Overall, aluminum coils are an excellent choice for architectural applications due to their strength, durability, and flexibility.

- Q: Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

- Q: Aluminum metal is oxidized in aqueous base with water serving as the oxidizing agent. Al(s) + H2O(1) → Al(OH)4- + H2(g) (basic solution) Write a balanced equation for this reaction in basic solution.

- You need to add OH- ions on the left. 2Al + 2OH- + 6H2O ---- 2Al(OH4)- + 3H2

- Q: How do you store aluminum coils to prevent damage?

- To store aluminum coils and prevent damage, there are several important steps you can follow. First, it is crucial to ensure that the storage area is clean, dry, and free from any moisture or humidity. This is because moisture can lead to corrosion and damage the aluminum coils over time. Second, you should store the coils in an upright position, preferably on pallets or racks, to prevent any bending or warping. By keeping them upright, you minimize the risk of coil deformation and maintain their shape for future use. Furthermore, it is advisable to cover the coils with a protective material such as plastic or tarp to shield them from dust, dirt, and other contaminants. This protective layer will also isolate the coils from any potential chemical exposure that could accelerate corrosion. Additionally, it is essential to handle the coils with care during storage, as rough handling or dropping them can lead to dents or scratches. To prevent any physical damage, use appropriate lifting equipment, such as forklifts or cranes, when moving or stacking the coils. Lastly, it is recommended to periodically inspect the coils during storage to ensure there are no signs of damage or corrosion. Regular visual checks will allow you to identify any issues early on and take necessary steps to prevent further damage. By following these storage practices, you can effectively prevent damage to aluminum coils, ensuring their longevity and preserving their quality for future use.

- Q: What kind of sensor is appropriate for aluminum coil thickness measurement?

- Use two sensors of ZLDS10X series to make a thickness gauge

- Q: Why does the heat preservation aluminum roll bend when it is cooled?

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part or thick walled parts of the twists and turns of the phenomenon.

- Q: Are there any limitations on the bending or forming of aluminum coils?

- The bending or forming of aluminum coils does have limitations. Despite being a relatively malleable metal, aluminum does possess certain constraints in terms of bending or forming. Firstly, one limitation lies in the occurrence of cracks or fractures during the bending process. Unlike other metals, aluminum exhibits lower ductility, making it prone to cracking or breaking under excessive stress or strain. As a result, it is crucial to carefully manage the bending process to prevent over-stressing the aluminum coils and causing damage. Another limitation involves the spring-back effect. When aluminum is bent or formed, it naturally tends to slightly return to its original shape. This poses a challenge in achieving precise and accurate bends or forms, especially with complex shapes or tight tolerances. Moreover, the thickness and grade of the aluminum can impact its bendability. Thicker aluminum coils may necessitate more force or specialized equipment for bending, while different mechanical properties of specific aluminum alloys can influence their formability. To address these limitations, various techniques and tools can be employed. For instance, the use of specialized bending equipment like press brakes or roll forming machines can help control the bending process and minimize the risk of cracking or spring-back. Additionally, preheating the aluminum coils can enhance their ductility, making them more pliable for bending or forming. Considering these limitations and operating within defined parameters is essential for successful bending or forming of aluminum coils. Seeking advice and assistance from experts or manufacturers well-versed in aluminum processing can provide valuable guidance in effectively overcoming these limitations.

- Q: Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- For painted metal, supports, grips, vinyl seat, tires and spokes, use a solution of 1-part Simple Green to 30-parts water — spray onto soiled areas. Wipe immediately with damp cloth to rinse, followed by dry towel — making sure to completely dry the area cleaned. My point is to show that you are supposed to cut the Simple Green with 30 parts of water. MOST people don't do this step. Simple Green (and many other cleaners) are very concentrated. NEVER clean a bicycle with this kind of cleaner without proper dilution. Read labels. Follow directions. Full strength Simple Green has enough butyl solvent to corrode bare aluminum on brake surfaces on wheels and if the wheel is too wet it can actually melt the glue of the rim strip by seeping in the spoke holes. I have seen this at bike shops a lot. The cleaner (if sprayed full strength around bearings) over spray has the potential to break down the grease -- after all it is a degreaser. Always dampen a cloth or sponge in your cleaning solution and wipe down a bike. Don't spray it.

- Q: Is it safe to use aluminum coils in various applications?

- <p>Yes, aluminum coils are generally safe to use. They are widely used in various industries due to their excellent thermal conductivity, corrosion resistance, and lightweight properties. Aluminum coils are non-toxic and do not emit harmful substances, making them safe for applications such as food packaging and construction. However, safety can depend on specific uses and manufacturing processes, so it's important to ensure that the coils meet the required safety standards for their intended application.</p>

- Q: Can aluminum coils be used in signage applications?

- Yes, aluminum coils can be used in signage applications. Aluminum is a popular material for signage due to its durability, corrosion resistance, and lightweight nature. It can be easily formed into various shapes and sizes, making it suitable for different types of signage such as outdoor signs, billboards, trade show displays, and more. Additionally, aluminum coils offer excellent weather resistance, ensuring that the signage remains intact and vibrant even in harsh environmental conditions. The versatility and longevity of aluminum make it a preferred choice for signage applications in various industries.

Send your message to us

6061 Aluminum Coil Manufacture Gutter Roof Aluminum Composite Panel 1100 3003 PE PVDF Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords