1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

| Aluminum Alloy: | AA1100, 1050, 1060, 3003, 3004, 3005, 3103, 3105, 5005, 5052, 5083, 5754, 6061, 8011 |

| Temper: | O, H16, H18, H22, H24, H26, H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08, 0.18, 0.28, 0.38, 0.48, 0.6, 0.8, 1 mm) |

| (0.1, 0.15, 0.25, 0.35, 0.45 mm) | |

| Coil Width: | 30~1520mm china price color coated aluminium coil |

| Core Diameter: | 150/ 405/ 505mm |

| Coil Weight: | 1~2.5 tons each coil for 3003 colorful aluminium coil for acp |

| Coating Type: | PE, PVDF, back coatting, ACRYLIC, feve |

| Surface Type: | Smooth, Embossed, Mill finish, Coated, Brushed, etc. |

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE: more than 18 +-1micron |

| PVDF: more than 25+-1micron | |

| Back Coating: 8~10+-1micron | |

| Coating Color: | Color A: pure white, ivory, white matte, yellow white, opal, light gray, aluminum natural color etc. |

| Color B: blue, yellow, gray, black, dark gray etc. | |

| Color C: white silver gray, flash silver, champagne etc. | |

| Color D: violet, pure orange, orange, bright red, china red, dark blue, brown, green, laker blue, flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Advantage: | 1.High temperature resistant 3003 colorful aluminium coil for acp |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton, strong polar fumigation wooden pallet, steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, ASTM |

| Application: | acp, aluminum composite panel, roof, gutter, ceiling, facade, wall cladding, gutter,aluminum honeycomb panel,roller shutter, rolling shutter, truck body, rolling shutter door, etc. |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

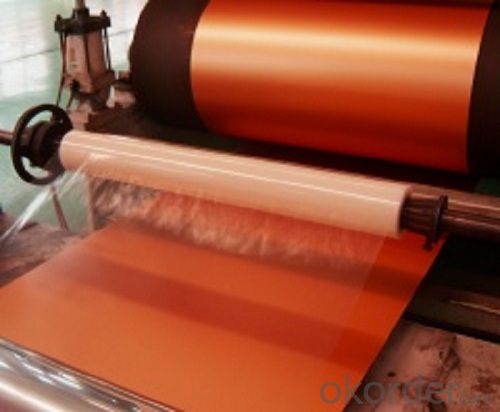

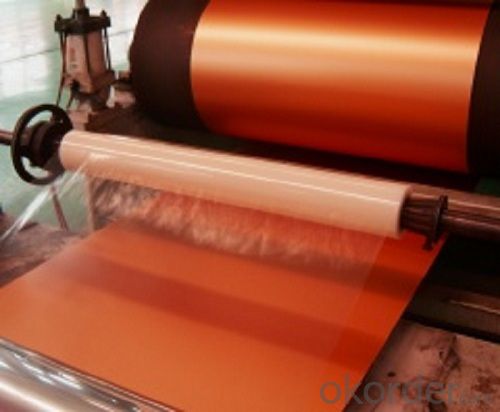

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Is it possible to use a magnet to determine if an aluminum coil has magnetic properties?

- <p>No, you cannot use a magnet to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not have magnetic properties and will not be attracted to a magnet. Magnets are used to test ferromagnetic materials like iron, nickel, and cobalt. To test for magnetic properties, you would need to use a different method, such as an electromagnetic induction test, which can detect magnetic fields generated by electrical currents in a coil.</p>

- Q: Can aluminum coils be used in corrosive gas environments?

- Corrosive gas environments can indeed accommodate the use of aluminum coils. Aluminum is widely recognized for its exceptional resistance to corrosion, particularly under atmospheric conditions. An oxide layer naturally develops on the metal's surface, acting as a safeguard against further corrosion. Nevertheless, it is crucial to acknowledge that aluminum is prone to vulnerability in the presence of specific corrosive gases, such as chloride and sulfur compounds. In such instances, it may be imperative to adopt supplementary protective measures, such as surface treatment or coating, to guarantee the durability and efficacy of the aluminum coils within corrosive gas environments.

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils are used in the production of sporting goods primarily for their lightweight and durable properties. They are commonly used in the manufacturing of sports equipment such as baseball bats, tennis rackets, and bicycles. The coils are shaped, formed, and molded into the desired product, providing strength and flexibility while reducing overall weight. This allows athletes to have better control, enhanced performance, and reduced fatigue during sports activities.

- Q: 1mm how much is one square meter for aluminum rolls?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.

- Q: How do aluminum coils contribute to sustainable packaging?

- Aluminum coils play a significant role in promoting sustainable packaging practices. Firstly, aluminum is an infinitely recyclable material, meaning it can be recycled repeatedly without losing its properties or quality. This feature enhances the sustainability of packaging as it reduces the need for extracting and processing virgin materials, thereby conserving natural resources and minimizing the environmental impact associated with mining and production. Moreover, aluminum coils offer exceptional barrier properties, effectively protecting the packaged goods from external factors such as moisture, light, and oxygen. This barrier function helps to extend the shelf life of products, reducing food waste and preventing the need for additional packaging or preservatives. By keeping products fresh for longer periods, aluminum coils contribute to sustainable packaging by supporting efforts to combat food loss and promote resource efficiency. Furthermore, aluminum is lightweight, making it an ideal material for packaging. Its low weight allows for reduced transportation costs and energy consumption during shipping, contributing to overall carbon emissions reduction. The lightweight nature of aluminum coils also makes them convenient for end consumers, reducing the environmental impact associated with disposal and recycling. Additionally, aluminum is highly durable and resistant to corrosion, ensuring the integrity of the packaging throughout its lifecycle. This durability means that aluminum coils can be reused or repurposed, further reducing waste and extending the material's lifespan. In summary, the use of aluminum coils in packaging promotes sustainability in multiple ways. It contributes to a circular economy by being infinitely recyclable, reduces food waste through effective barrier properties, lowers carbon emissions through lightweight design, and encourages reuse and repurposing due to its durability. By incorporating aluminum coils into packaging solutions, we can make significant strides towards achieving a more sustainable and environmentally friendly packaging industry.

- Q: Can the displacement sensor be used for real-time measurement of the aluminum coil thickness?

- You are suggested to use eddy current displacement sensor KD2306 to measure aluminum.

- Q: Are there any specific guidelines for the installation of aluminum coils?

- Yes, there are specific guidelines for the installation of aluminum coils. When installing aluminum coils, it is important to follow manufacturer's instructions and adhere to industry standards. Some specific guidelines for the installation of aluminum coils include: 1. Proper handling: Aluminum coils should be handled with care to prevent damage. It is recommended to use gloves and avoid dropping or dragging the coils during installation. 2. Compatibility: Ensure that the aluminum coils are compatible with the HVAC system you are installing. Consider factors such as coil size, capacity, and refrigerant type. 3. Coil orientation: Pay attention to the correct orientation of the coil during installation. This includes ensuring that the airflow direction matches the system's requirements. 4. Alignment: Proper alignment of the aluminum coil is crucial for efficient operation. Make sure the coil is level and securely attached to the mounting brackets. 5. Condensate drainage: Ensure that the condensate drain pans and lines are properly installed and functioning. This helps in preventing water leakage and potential damage. 6. Electrical connections: Follow electrical guidelines provided by the manufacturer to ensure proper wiring and connections for the aluminum coil. 7. Insulation: Insulate the refrigerant lines and ductwork as required to prevent condensation and improve energy efficiency. 8. Clearances: Maintain adequate clearances around the aluminum coil for proper airflow and service access. This includes ensuring that there is enough space for cleaning and maintenance. 9. Testing: After installation, perform necessary tests and inspections to ensure the aluminum coil is functioning properly. This may include checking for refrigerant leaks, verifying proper airflow, and testing the system's performance. It is important to consult the manufacturer's installation instructions and any applicable building codes or regulations before installing aluminum coils. Following these specific guidelines will help ensure a successful installation and optimal performance of the aluminum coils.

- Q: How are aluminum coils typically stored and transported?

- Aluminum coils are typically stored and transported in a way that ensures their protection and prevents any damage. They are usually stored in a warehouse or storage facility where they are kept in a vertical position. This vertical storage helps to prevent any bending or warping of the coils. When it comes to transportation, aluminum coils are often transported using specialized coil trailers or flatbed trucks. These trailers are designed to securely hold the coils in place during transit. The coils are typically secured using straps or bands to prevent any movement or shifting while on the road. Additionally, it is common for aluminum coils to be wrapped in protective materials such as plastic or cardboard to provide an extra layer of protection against moisture, dirt, and other potential hazards during transportation. It is important to handle aluminum coils with care to avoid any damage, as even small dents or scratches can affect their performance. Therefore, proper storage and transport methods are crucial to ensure that the coils arrive at their destination in optimal condition.

- Q: I go on a trip once a year with a group of lets say 10 people, we go for 7 nights and consume on average approx 120 cans of beer each (throughout the week). We have a fire burning the whole time in a hole that we dig approx 1ft deep, then we dispose of each can in the fire and let them melt down never thinking about them again. That's approx 1,200 cans that melt in the one fire hole.Will the aluminum have an affect on the soil? does anyone know what sort of damage this can cause? and for what distance / area around the fire might be affected?The theory amongst the group is that cans do not hurt anything so that's why they take cans instead of glass.Thanks

- Aluminum is very reactive in air and will form a layer of aluminum oxide around the outside of any piece. This oxide layer is very stable which is why aluminum doesn't corrode. Since your block of aluminum will be totally oxidized being in a fire, it's inert and just going to sit in the hole for the foreseeable future. The burning paint might not be healthy to breath but that's about the only hazard. Most common soil is a mixture of aluminum, carbon and silica compounds anyways so you aren't even adding anything particularly exotic. Alternatively, you could bring along a couple fifths of whiskey. It's lighter and has less packaging so it's the environmentally friendly way to get drunk.

- Q: Is it possible to use aluminum coil for crafting decorative items?

- <p>Yes, you can use aluminum coil to make a decoration piece. Aluminum is a versatile material that is lightweight, durable, and easy to manipulate. It can be bent, twisted, or cut into various shapes to create unique decorative items. Common uses include making sculptures, wall art, and even jewelry. Due to its malleability and resistance to corrosion, aluminum coil is an excellent choice for decorative purposes, especially for outdoor decorations where weather resistance is important.</p>

Send your message to us

1060 Aluminum Coil Gutter Roof Aluminium Coil PE PVDF Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords